External automatic dust removal assembly of equipment

A technology of dust removal components and equipment, which is applied in the direction of chemical instruments and methods, cleaning methods using gas flow, cleaning methods and utensils, etc., and can solve problems such as complex structures of large equipment, abnormal operation of equipment, and inconvenient cleaning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

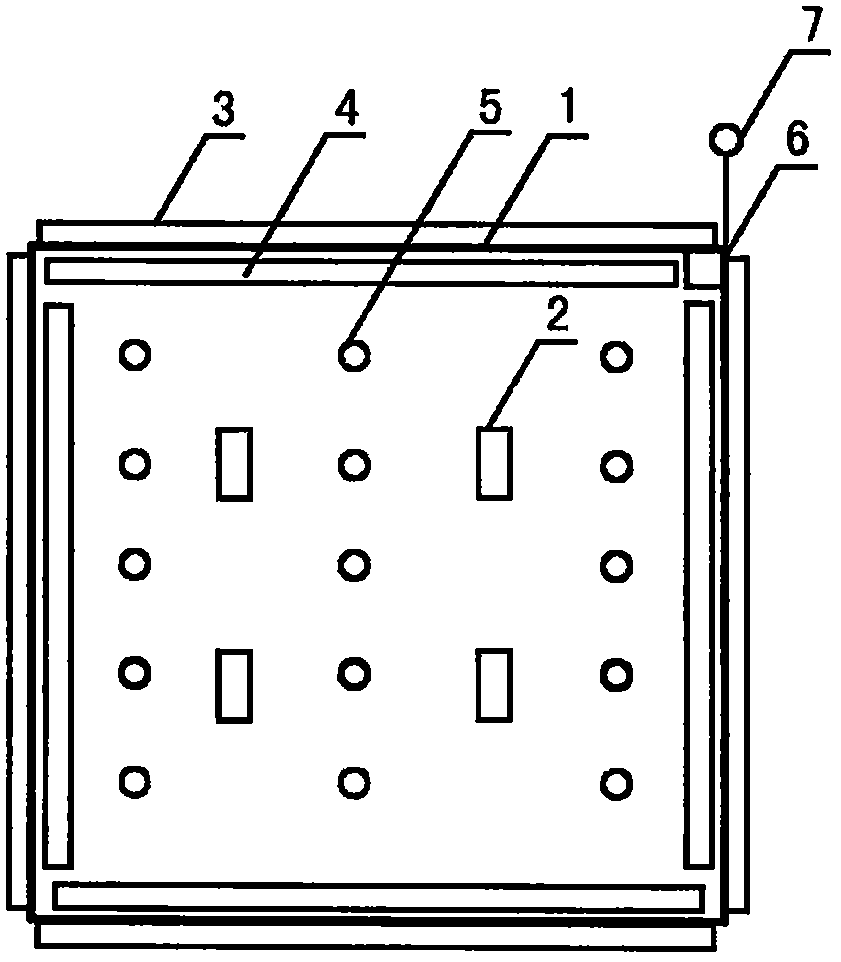

[0012] Embodiment: as shown in the accompanying drawing. The equipment is externally connected to an automatic dust removal component, including a cover (1), which is made of soft material and can hang down naturally. Four fixing modules (2) are evenly arranged in the middle of the inside of the cover to fix the cover on the outside of the equipment, and set heavy objects on the four sides of the cover (3), so that the four sides are not blown up when the outer cover is fixed on the equipment.

[0013] The equipment is externally connected with an automatic dust removal component, and air blowing components (4) are arranged on the four sides of the outer cover, and in the outer cover inside the heavy object, air is injected into the inside when starting.

[0014] The equipment is externally connected with an automatic dust removal component, and a plurality of ventilation holes (5) are evenly arranged on the outer cover to discharge internal gas and dust outward.

[0015] The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com