A modular test support clamping device

A technology for supporting clamping and guide rails, applied in the direction of measuring devices, instruments, measuring instrument components, etc., it can solve the problems such as the inability to flexibly attach the heat dissipation surface and the cold plate, the heat dissipation effect cannot meet the requirements, and the damage to the surface of the module, so as to reduce the number of scratches. Damage, strength should not be deformed, and the effect of reducing installation tolerance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

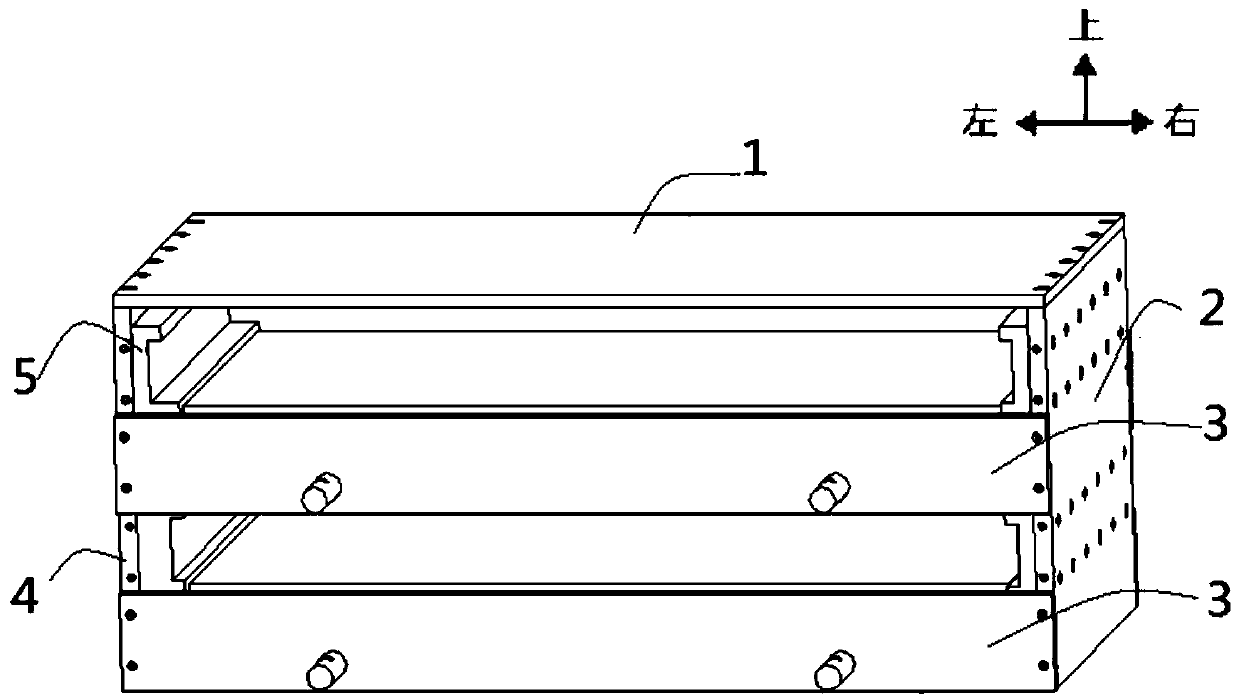

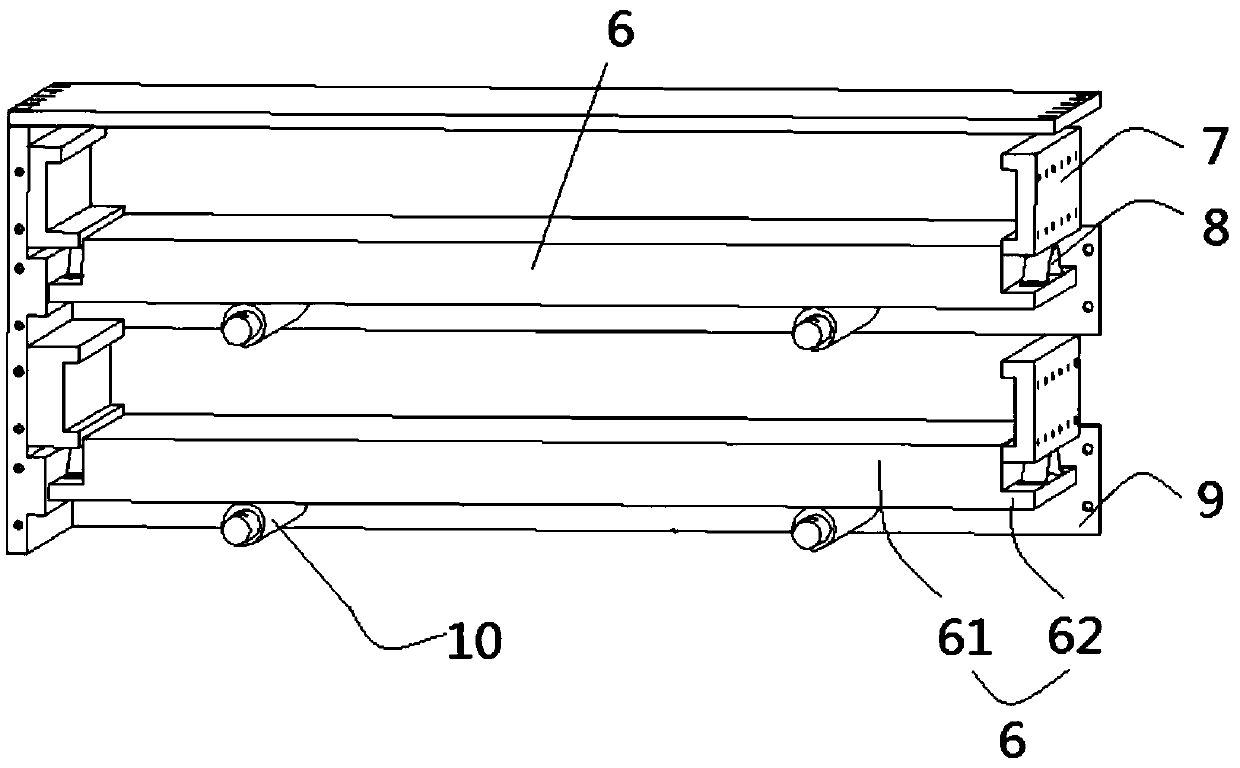

[0033] Such as figure 1 with 2 As shown, the present invention provides a modular test support clamping device, comprising:

[0034] The shell, the shell includes an upper plate 1, a left side plate 4, a right side plate 2, a front baffle 3 and a rear baffle 9, the upper plate 1, the left side plate 4, the right side plate 2, the front baffle 3 and tailgate 9 siege square frame;

[0035] The first guide rail 5, the first guide rail 5 is connected with the inner wall of the left side plate 4;

[0036] The second guide rail 7, the second guide rail 7 is connected to the inner wall of the right side plate 2, the second guide rail 7 is arranged opposite to the first guide rail 5, and the first guide rail 5 and the second guide rail 7 are composed for placing The slideway of the module, the slideway and the front baffle 3 are arranged in a staggered manner;

[0037] The eccentric rod 10, the eccentric rod 10 is a stepped straight axis whose axes are parallel but not coincident....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com