Multidirectional micro-nano force measurement device and method

A measurement device and measurement method technology, applied in the field of force measurement, can solve the problem of not meeting the high requirements of micro-nano Newton-level force value measurement, unable to measure micro-nano force value, etc., to overcome the non-vertical direction micro-nano force Value measurement, reduce measurement costs, meet high requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

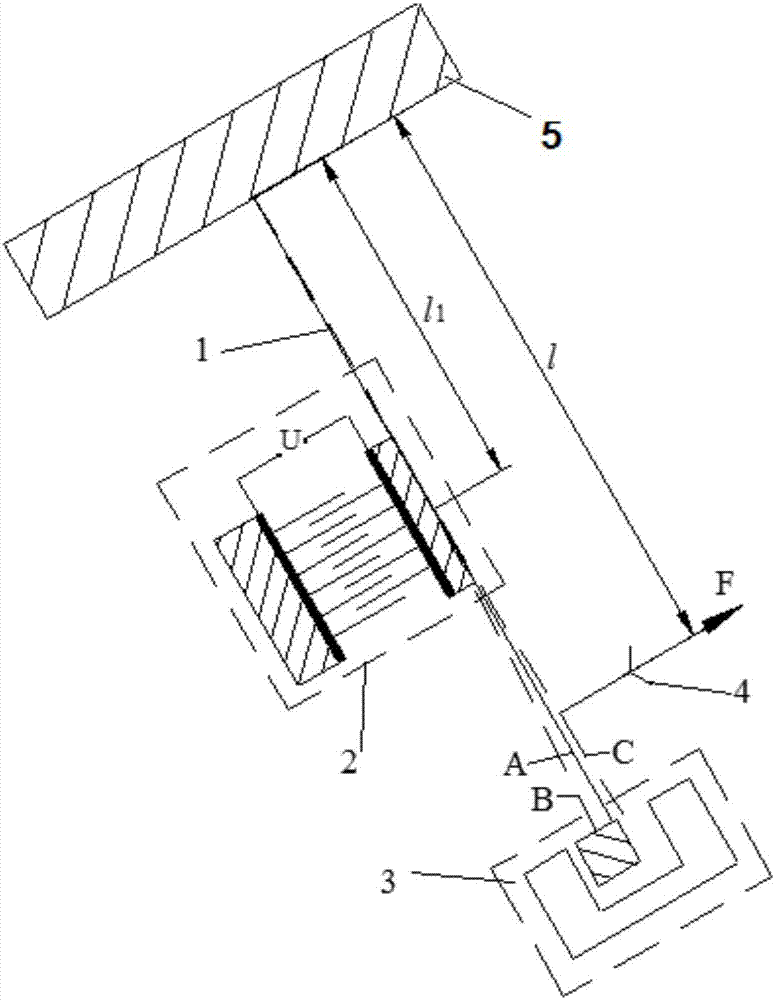

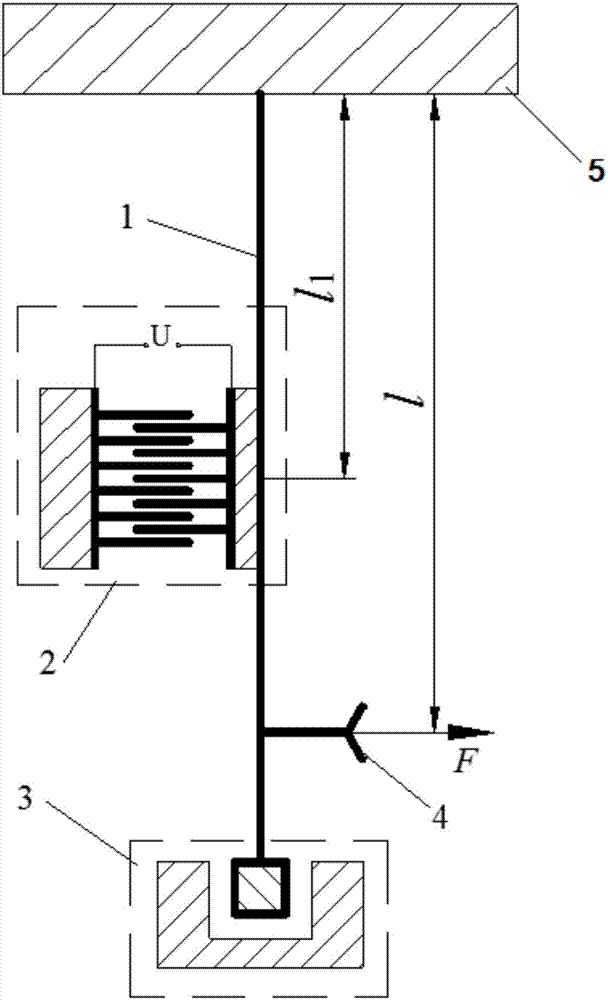

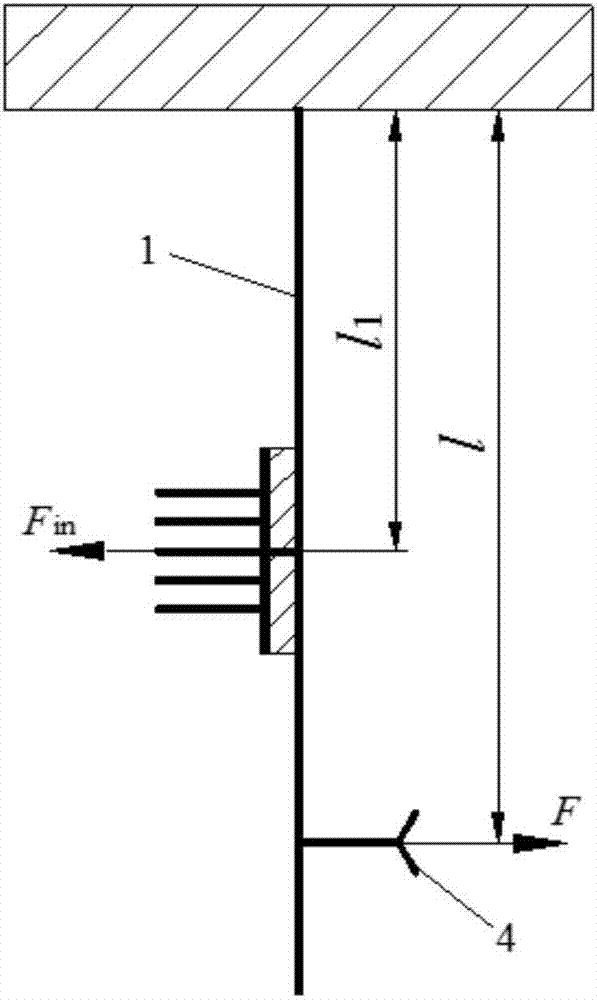

[0069] Taking the measuring device of the present invention when measuring the micro-nano force in the horizontal direction as an example, the measuring device is mainly composed of five parts, 1 is an elastic support mechanism, which is mainly used to receive the micro-nano force value and the standard micro-nano force value applied by the outside world And a small deformation occurs; 2 is the standard micro-nano force value generating device, which is mainly used as a force source to generate a standard micro-nano force value that is balanced with the measured micro-nano force value; 3 is a position measurement device, mainly used to determine the elastic support mechanism 1 4 is the loading mechanism, which is used to load the measured micro-nano force value; 5 is the fixed plate, which is used to fix the front end of the elastic support mechanism.

[0070] Among them, the elastic support mechanism 1 of the present invention can adopt figure 2 elastic devices of the shape,...

no. 2 example

[0086] When the micro-nano force measuring device of the present invention measures the micro-nano force in any direction in space, its working principle is as follows: figure 1 shown.

[0087] Taking the standard micro-nano-force value generating device as an interdigitated capacitor device as an example, due to the existence of the micro-nano-force measuring device's own weight, the elastic support mechanism 1 will be slightly deformed, and its position will change from position A to position B. At the same time, the slight deformation of the elastic support structure 1 causes a slight change in the position between the two fingers of the standard electrostatic micro-nano force generating device 2 . At this point, the initial equilibrium position of the micro-nano force measuring device of the present invention is the position where the elastic support mechanism 1 is slightly deformed (such as figure 1 Indicated by the dotted line B), that is to say, when the micro-nano for...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com