Polarizing plate, polarizing film, and method for manufacturing polarizing plate

A manufacturing method and polarizer technology, applied in polarizing components, instruments, optics, etc., can solve the problems of uneven thickness distribution of polarizers, uneven thickness distribution of polarizers, etc., and achieve the effect of reducing unevenness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

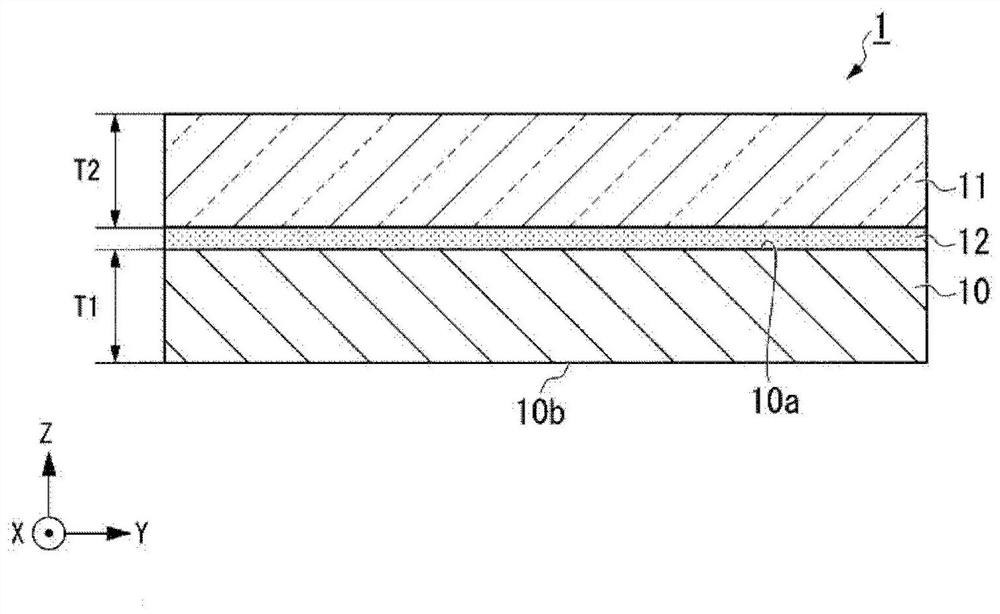

[0146] The planarization of the coating liquid for resin layers with respect to the heat-shrinkable shape of a base film among the causes of the large thickness distribution of a polarizing plate in the thin polarizing plate manufacturing method was verified. Figure 9 It is a cross-sectional view showing a verification laminate 2 produced as a verification example. It should be noted that, in Figure 9 In , the same reference numerals are assigned to the same configurations as those in the above-mentioned embodiment.

[0147] The laminated body 2 for verification is equipped with the base film 20, the primer layer 32, and resin layer 134a, 134b. The resin layer 134a is formed on the upper surface 20a of the base film 20 via the primer layer 32 . The resin layer 134b is formed on the lower surface 20b of the base film 20 via the primer layer 32 . The upper surface of the resin layer 134a and the lower surface of the resin layer 134b are flat surfaces.

[0148] In this veri...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com