Commutation torque fluctuation suppression method of brushless DC motor driven by non-inductive boost topology

A brushed DC motor and fluctuation suppression technology, applied in torque ripple control, electronic commutator and other directions, can solve the problem of many power switches of the front-stage DC-DC converter, increase the volume and cost of the drive system, and prolong the commutation process time. and other problems, to achieve the effect of shortening the commutation process time, less power devices, and simple topology structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

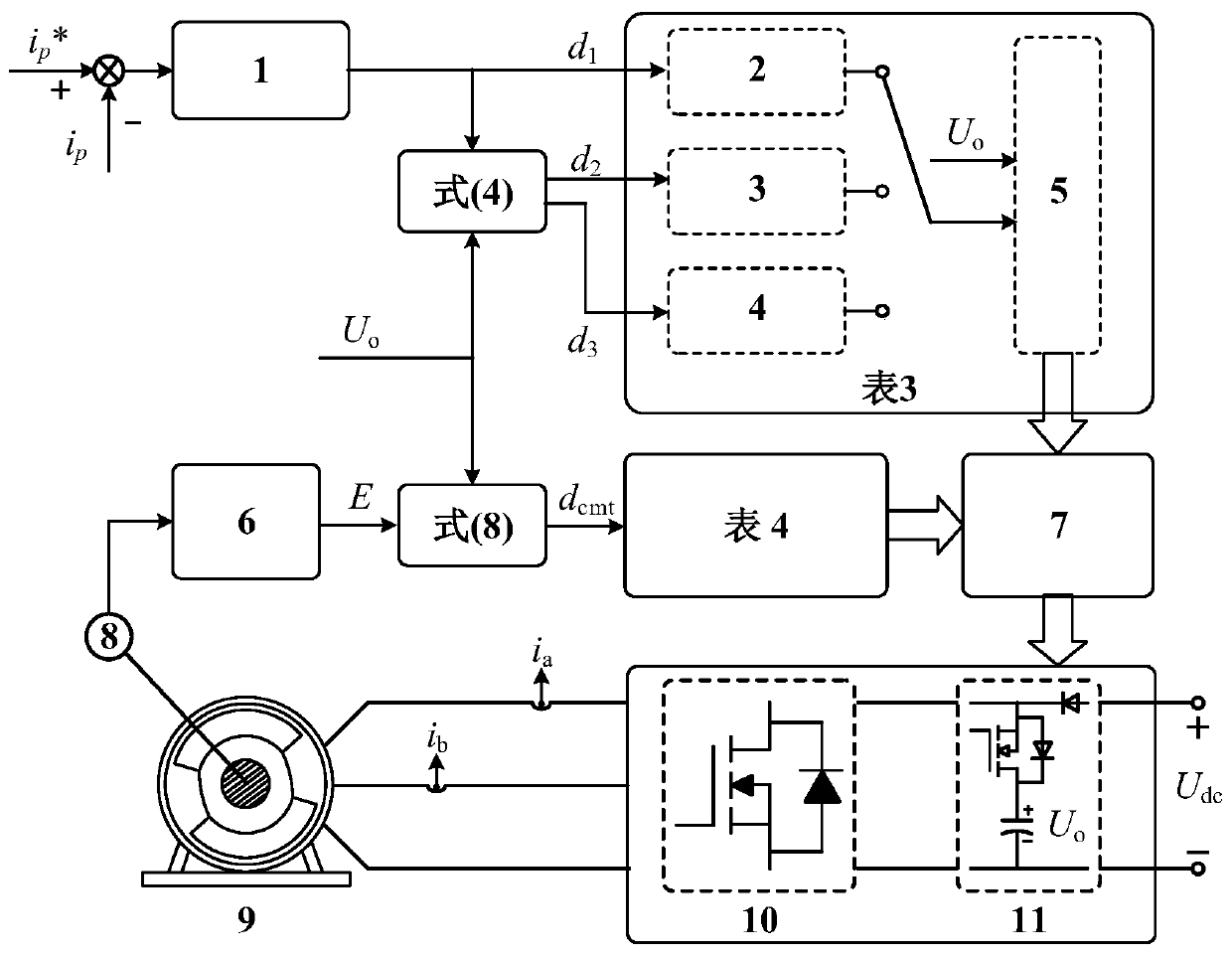

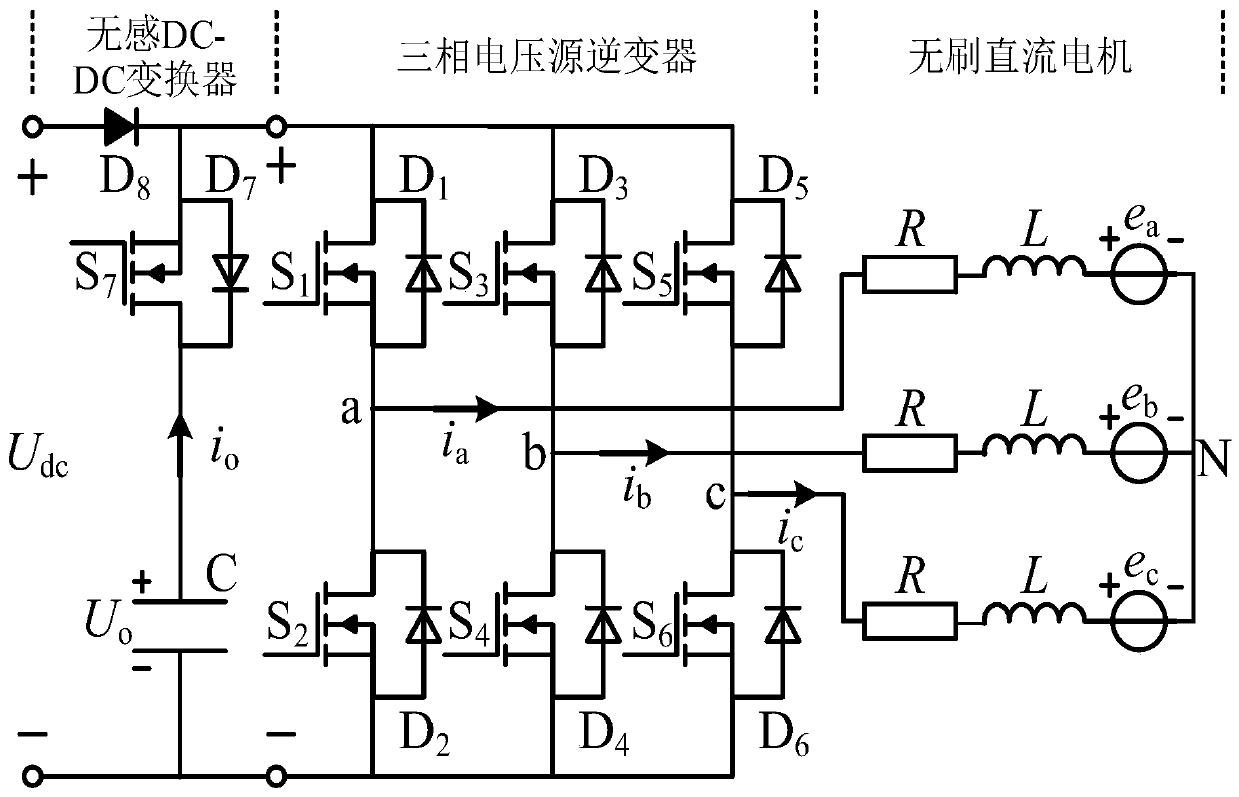

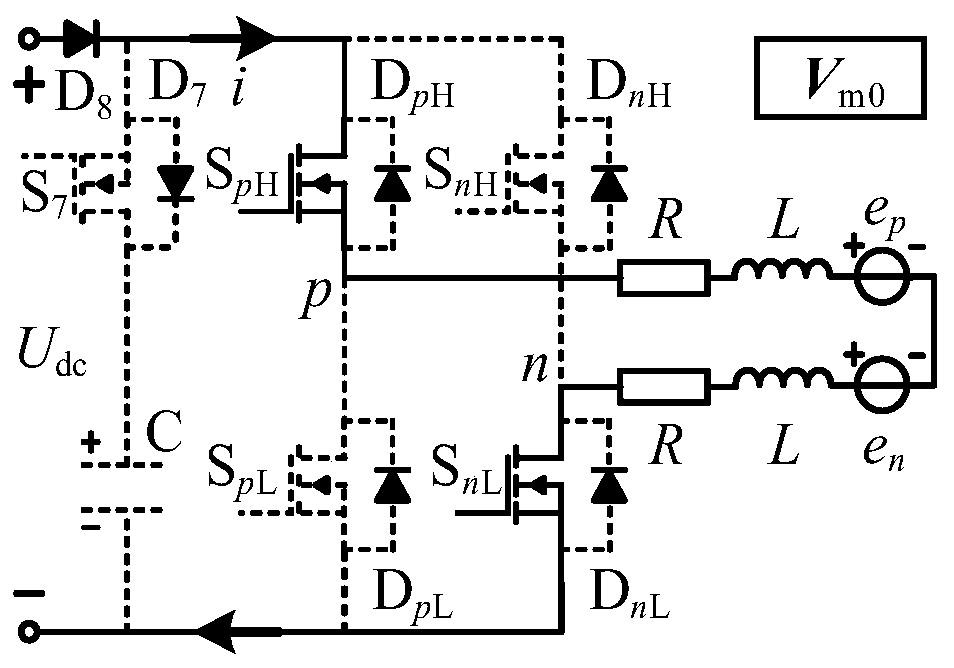

[0043] The method for suppressing the commutation torque fluctuation of the brushless DC motor driven by the non-inductive boost topology of the present invention will be described in detail below with reference to the embodiments and the accompanying drawings.

[0044] like figure 1 shown. The method for suppressing the commutation torque fluctuation of the brushless DC motor driven by the non-inductive boost topology of the present invention is a control method for selecting a non-commutation area or a commutation area by judging the working area. In the non-commutation area, the output voltage of the non-inductive DC-DC boost topology is adjusted under the premise of ensuring the normal speed regulation of the motor by selecting the working mode reasonably. In the commutation area, the output voltage of the non-inductive DC-DC boost topology is used, and a unified switching vector is used to suppress the commutation torque fluctuation and shorten the commutation time.

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com