Making machine used for production of air column bags for packaging

An air column bag and bag making machine technology, which is applied in packaging, bag making operations, transportation and packaging, etc., can solve the problems of high production cost and low efficiency, and achieve time and energy saving, convenient operation and high feeding efficiency high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] Below in conjunction with accompanying drawing, the present invention will be further described.

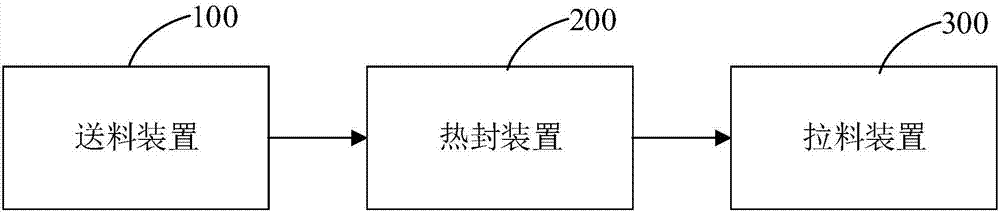

[0041] Such as figure 1 As shown, a bag making machine for producing air column bags for packaging includes a conveyor belt, and a feeding device 100 , a heat sealing device 200 and a pulling device 300 arranged in sequence along the moving direction of the conveyor belt.

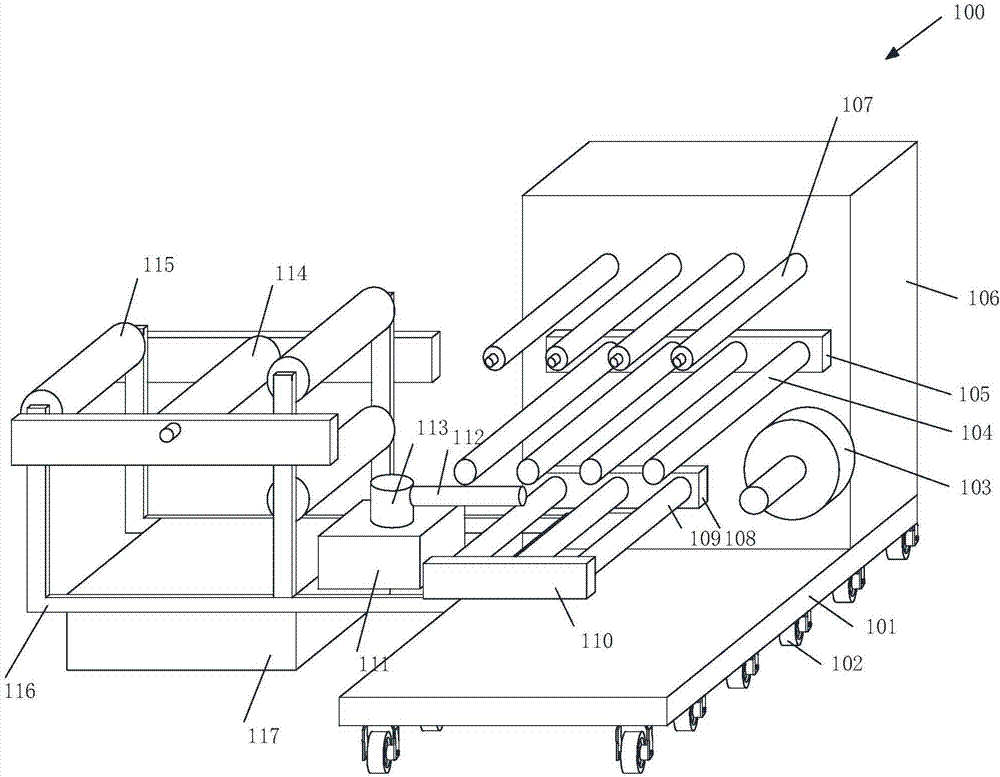

[0042] Such as figure 2 As shown, the feeding device 100 includes a feeding base 101. The feeding base 101 is made of 304 stainless steel, which is easy to clean, durable and has a long service life. One side of the first connecting seat 105 and the second connecting seat 108 are provided, and a row of first rotating rollers 104 is rotatably connected on the first connecting seat 105, and two rotating rods 109 are rotatably connected on the second connecting seat 108, two A fixed frame 110 is provided on the side of the rotating rod 109 away from the second connecting seat 108, a second rotating roll...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com