Train wing plate reduction device based on worm gear transmission

A technology of reduction gear and worm drive, which is applied in the direction of pneumatic brake, transportation and packaging, railway car body parts, etc. It can solve the problems of harsh installation position selection, large driving force for opening the flap, and occupying the inner space of the car body, etc., to achieve processing Easy to install, ensure safety and reliability, and facilitate installation and maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with the embodiments shown in the accompanying drawings.

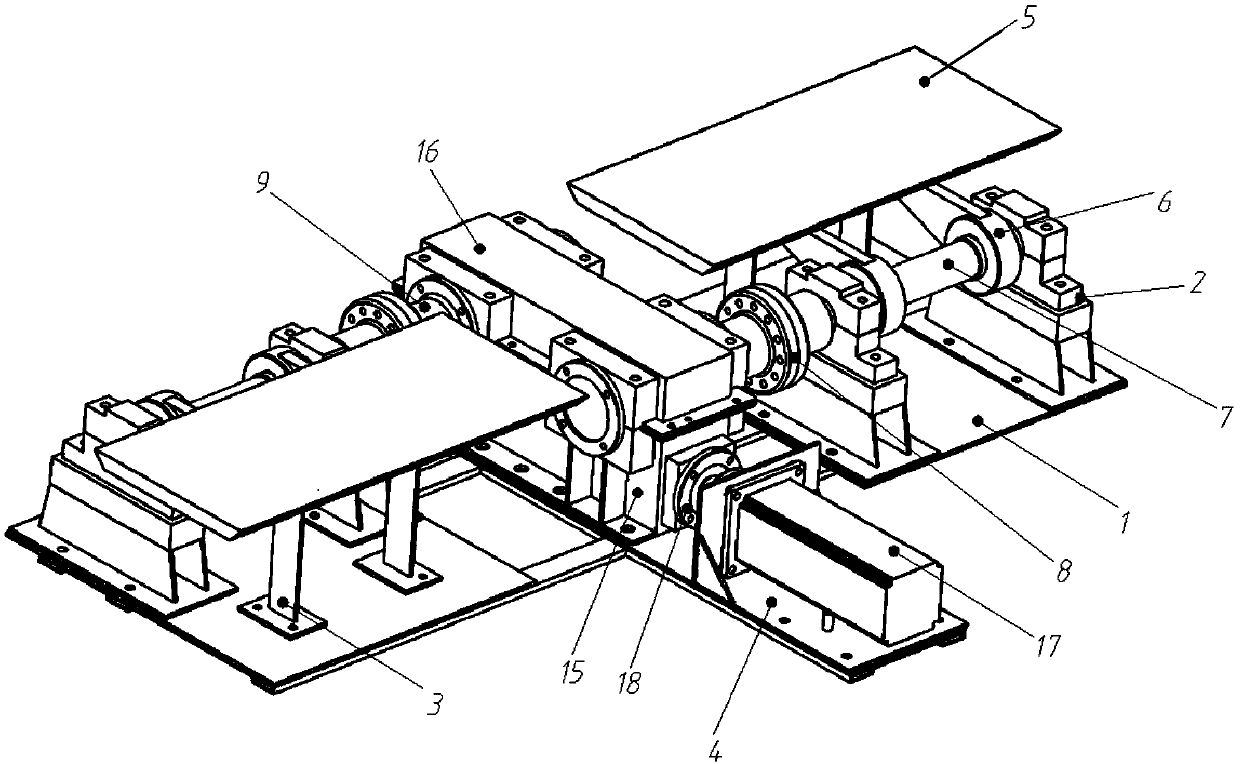

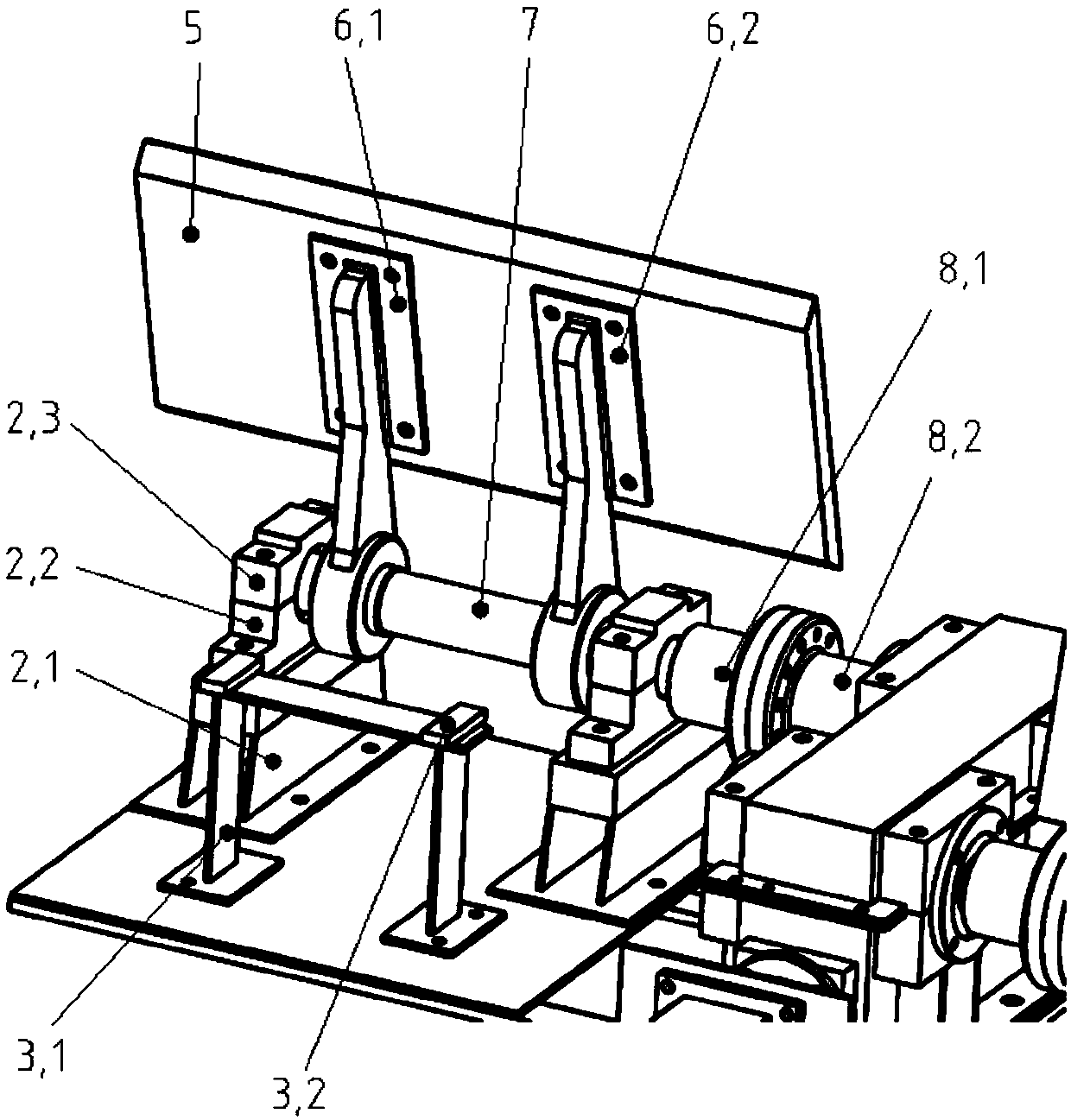

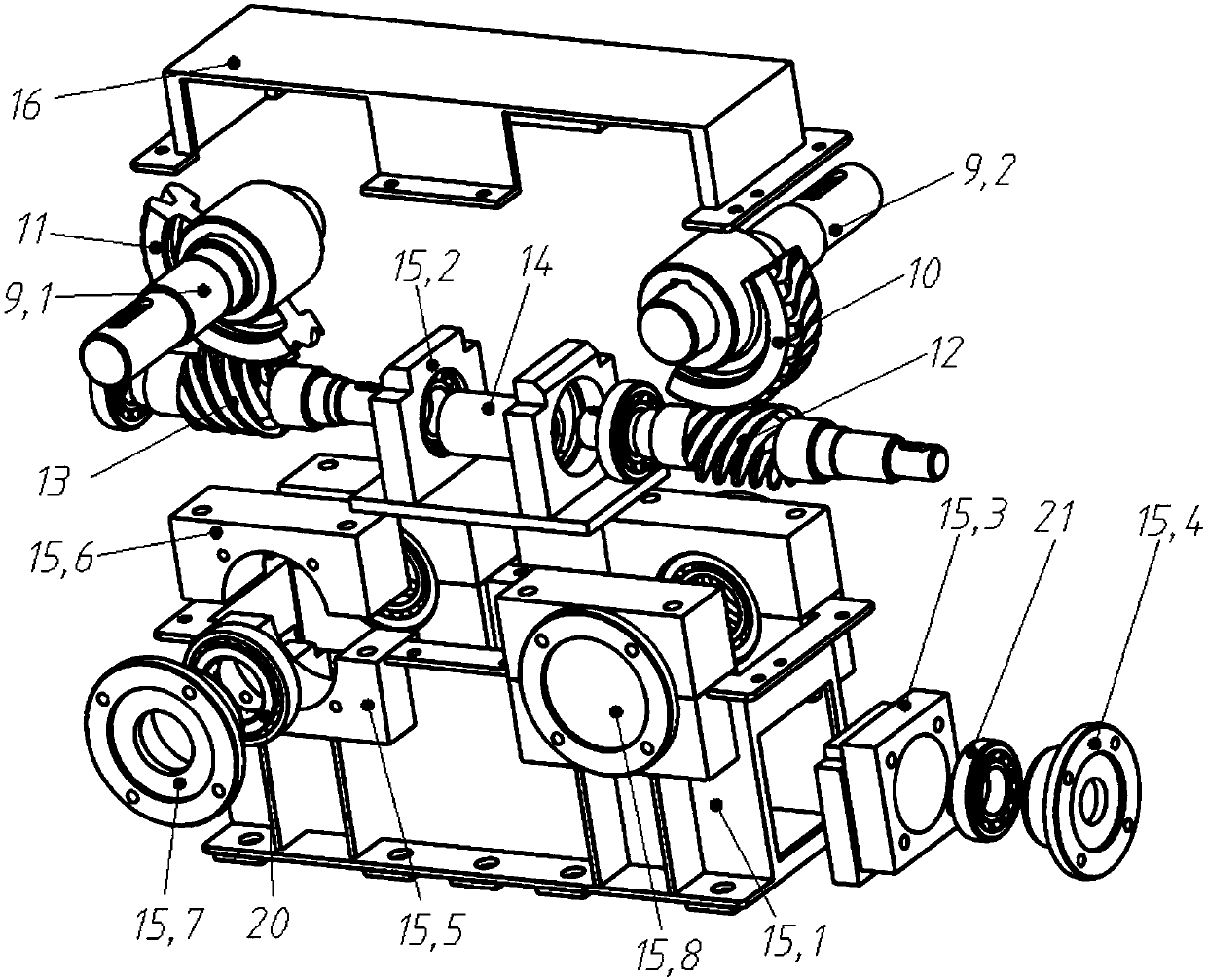

[0027] Such as figure 1 and figure 2 As shown, the present invention firstly provides a train wing plate reduction device based on worm and gear transmission, which includes four main parts: a positioning mechanism, a wing plate mechanism, a worm and gear mechanism and a driving mechanism.

[0028] Specifically, it mainly includes a mounting base 1, a wing plate bearing seat and a bracket 2 (that is, the above-mentioned rotating shaft support), an electromagnet and a bracket 3, a motor mounting frame 4, a wing plate surface 5, a wing plate rotating arm 6, and a wing plate Rotary shaft 7, wing plate-worm gear coupling 8 (that is, the above-mentioned wing plate rotating shaft coupling), worm gear shaft 9, left-handed worm wheel ring 10, right-handed worm wheel ring 11, left-handed worm shaft 12, right-handed worm shaft 13, worm - Worm coupling...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com