Mechanical gear progress fine adjustment device

A technology of fine-tuning devices and gears, which is applied in the direction of conveyor objects, transportation and packaging, etc. It can solve the problems of multiple objects being confused, not working properly, and the upper operating device cannot be aligned.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

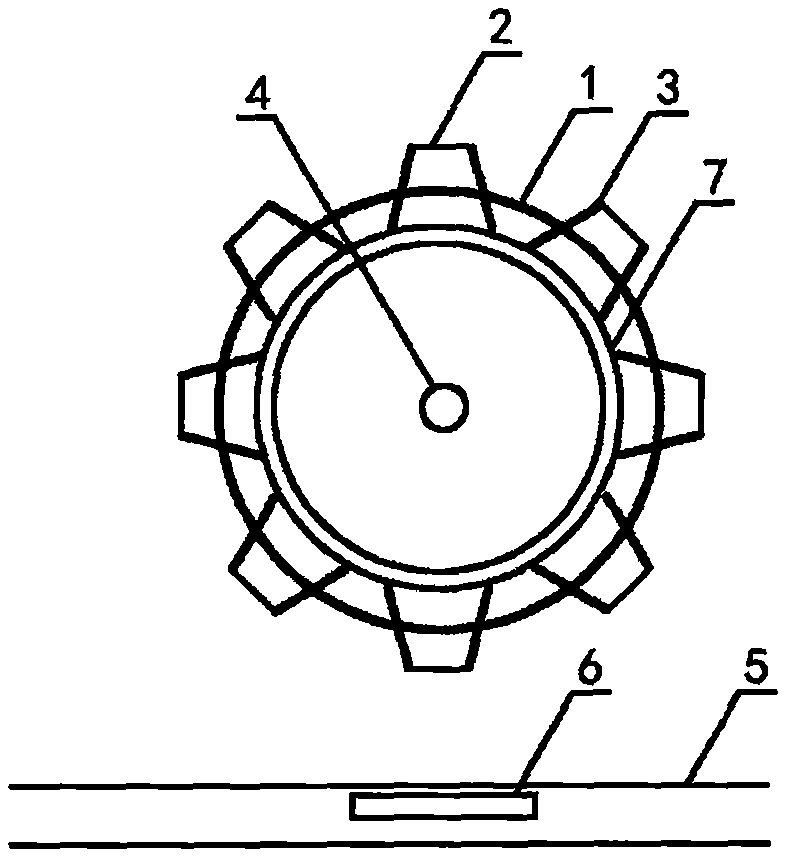

[0012] Embodiment: as shown in the accompanying drawing. The mechanical gear progress fine-tuning device includes a disc (1), and a plurality of gears (2) are evenly arranged on the circumference of the disc. The gears are embedded in the circular turntable, and the gears are moved through the tracks (3) set on both sides of the gears. Protrusion and retraction adjust the work progress of the operation.

[0013] Mechanical gear progress fine-tuning device, the rotating shaft (4) is arranged in the center of the disc, and the gears on it are driven by circular rotation.

[0014] The mechanical gear progress fine-tuning device is provided with an assembly line device (5) under the operation gear, and various operation parts are assembled.

[0015] The mechanical gear progress fine-tuning device is provided with a speedometer (6) on the assembly line device to measure the real-time speed of the object operation on the assembly line.

[0016] The mechanical gear progress fine-tu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com