An energy-saving and long-life ultraviolet curing furnace and its control method

A curing furnace and ultraviolet light technology, applied in the field of optical fiber production, can solve the problems of internal temperature affecting the service life of components, low heat dissipation efficiency of curing furnace, unstable curing quality, etc., to ensure continuous stability, reduce maintenance time, improve The effect of cooling efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

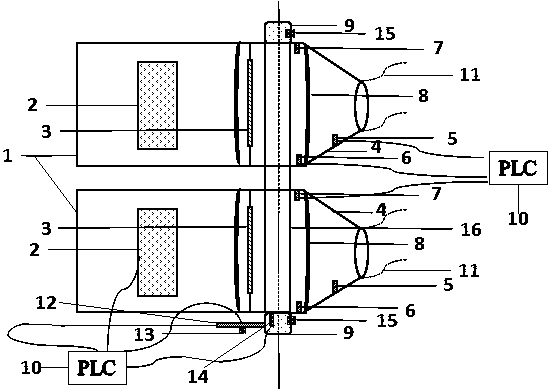

[0049] as attached figure 1 , the curing furnace adopts the upper and lower combination of two curing furnaces 1, the main structure of the temperature control part in the furnace is designed as a trapezoidal heat dissipation cover 4, the tail of the trapezoidal heat dissipation cover 4 is connected with the heat dissipation return air pipe 11, and the front part of the trapezoidal heat dissipation cover 4 is connected with The main body of the curing furnace 1 is connected, and the metal wall at the front of the trapezoidal heat dissipation cover is at an angle of 45-60° with the vertical direction of the main body of the curing furnace to enhance the smoothness of the heat dissipation airflow and reduce the pollution degree of the reflective auxiliary cover.

[0050] A wind speed sensor controller 5 is arranged in the middle of the wall of the trapezoidal cooling cover 4 , and the wind speed sensor controller 5 feeds back the wind speed flow data to the PLC controller 10 of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com