Liquid-gas coexistence type buffering device and buffering device array

A buffer device and liquid-gas technology, applied in the direction of gas-liquid shock absorbers, springs, shock absorbers, etc., can solve the problems of increasing the degree of injury to people inside the vehicle, making it difficult to protect the life safety of the vehicle, and reducing the impact force of impacts, etc., to achieve Increase the scope of application, increase the scope and flexibility of application, and reduce the effect of destructive force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

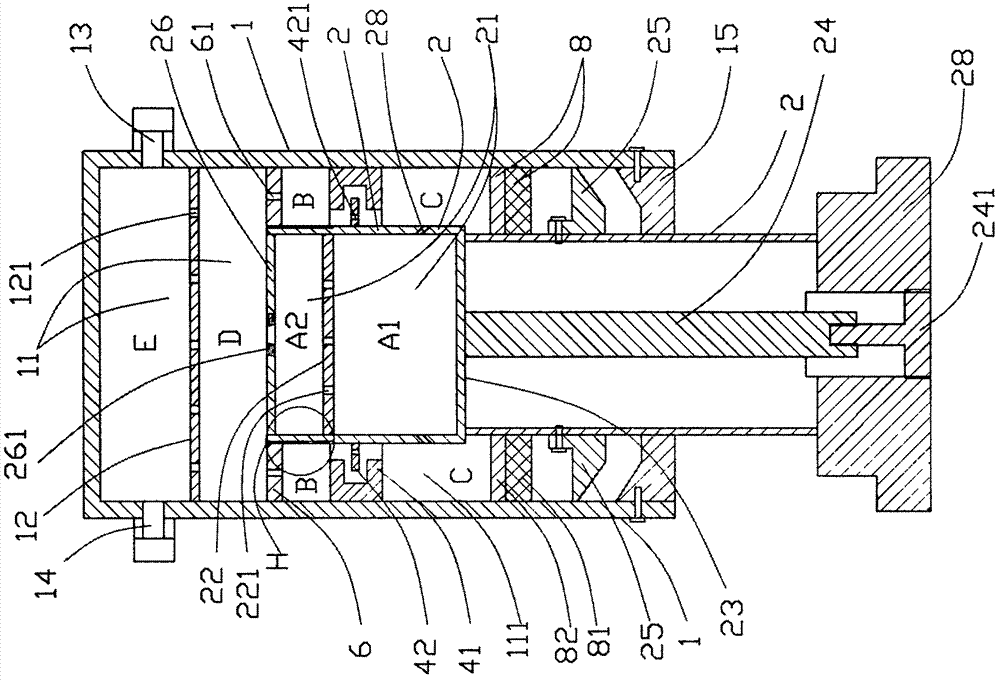

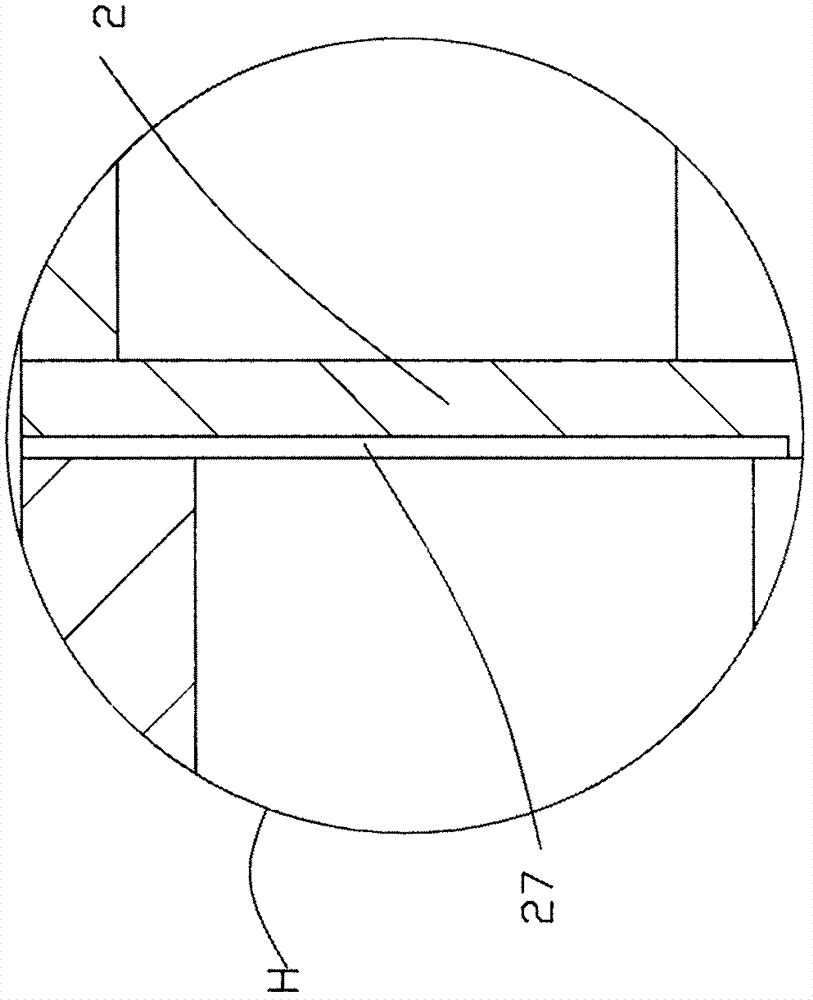

[0037] Such as Figure 1-2 As shown, a buffer device for coexistence of liquid and gas includes an outer cylinder 1 and an inner cylinder 2, and the outer cylinder 1 and the inner cylinder 2 are in a cylindrical structure as a whole (that is, have an outer wall and a bottom plate, and an inner cavity with an opening ), the outer cylinder 1 is provided with an outer cylinder cavity 11 for containing buffer liquid and gas and installing the inner cylinder 2, and the outer cylinder cavity 11 is divided into a gas cavity (such as figure 1Shown E chamber) and liquid chamber (D chamber); Inner cylinder 2 is provided with the inner cylinder lumen 21 that is used for containing buffered liquid.

[0038] On the outer cylinder 1, an outer cylinder restrictor plate 12 (can be more than one) is fixedly installed in the inner cavity 11 of the outer cylinder, and the outer cylinder restrictor plate 12 is used to control the speed at which the buffer liquid flows from the liquid chamber to t...

Embodiment 2

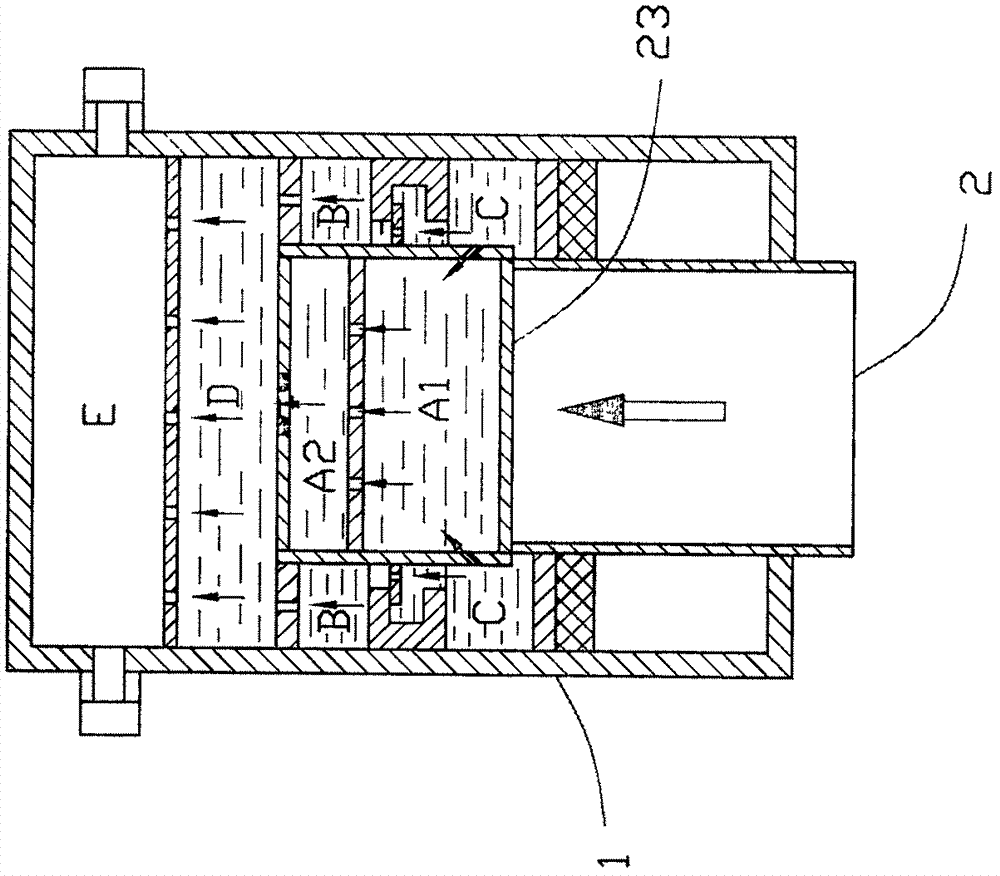

[0053] Such as Figure 4-5 As shown, a buffer device for the coexistence of liquid and gas includes an outer cylinder 1 and an inner cylinder 2. Both the outer cylinder 1 and the inner cylinder 2 have a cylindrical structure as a whole. The outer cylinder inner cavity 11 of the inner cylinder 2, the outer cylinder inner cavity 11 is divided into a gas cavity (such as figure 1 Shown E chamber) and liquid chamber (D chamber); Inner cylinder 2 is provided with the inner cylinder lumen 21 that is used for containing buffered liquid.

[0054] The main difference between it and Embodiment 1 is that the outer tube restrictor plate 12 is curled into a tubular shape, and one end thereof is installed on the bottom plate of the outer tube 1; the inner piston 26 is installed on the other end of the outer tube restrictor plate 12, and the outer circumference of the inner piston 26 is The inner wall of the inner cylinder 2 is movably socketed, that is, the inner piston 26 is movably sleeve...

Embodiment 3

[0056] Such as Figure 6 Shown, a kind of buffer device array that liquid gas coexists, by two (or more than two) embodiment 1 (as Figure 6 shown) or embodiment 2 (the accompanying drawings do not show this combination structure), two or more buffer devices are arranged side by side and connected as a whole, specifically it may be: Also comprise public base 16 and public anti-collision beam 17, the bottom plate of the outer tube 1 of each buffer device is all connected on the common base 16, and the impact protection plate 28 of the outer tube 1 of each buffer device is all connected on the public anti-collision beam 17 The public anti-collision beam 17 is provided with an air bag 18; the cascading nozzles 13 of the outer cylinder 1 of each buffer device are connected in turn, so that the pressure is balanced during the collision, and the shrinkage of the inner cylinder 1 can be consistent.

[0057]The outer cylinder 1 at both ends of the buffer device array is symmetrically...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com