Pitot tube velocity meter or flowmeter being free from influence of flow velocity in non-measuring direction

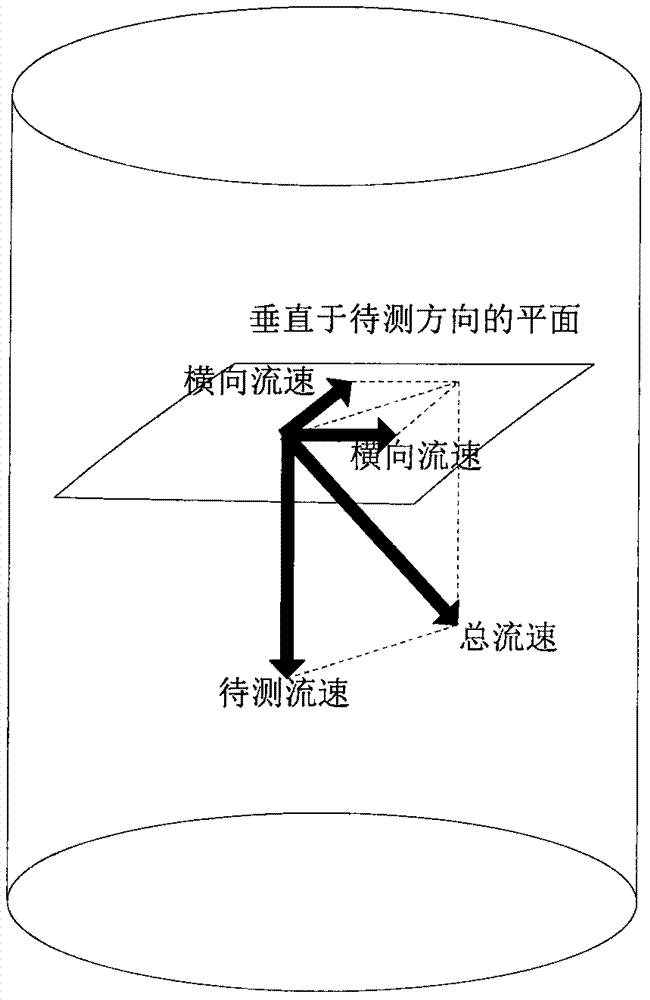

A technology of pitot tube and flow meter, which is applied in the direction of volume/mass flow generated by measuring pressure difference to detect fluid flow and mechanical effects, which can solve the measurement uncertainty, the inability to determine the direction of flow velocity, and the inability of pitot tube to identify the direction of flow velocity, etc. problem, to avoid the impact of

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] In order to facilitate the understanding of the present invention, the embodiments of the present invention will be described below in conjunction with the accompanying drawings. Those skilled in the art should understand that the following description is only for the convenience of explaining the present invention, not as a specific limitation on its scope.

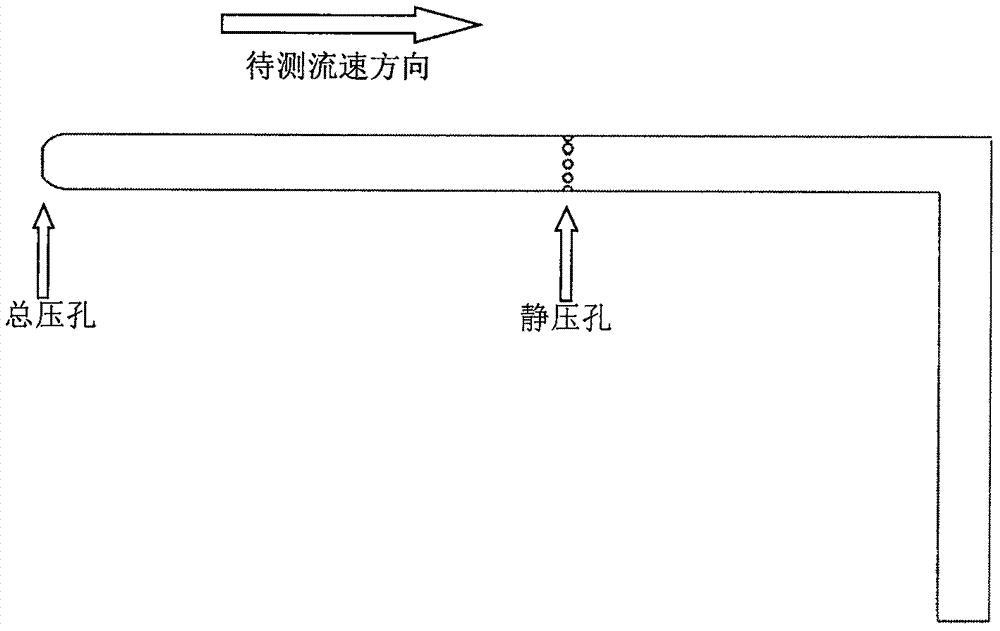

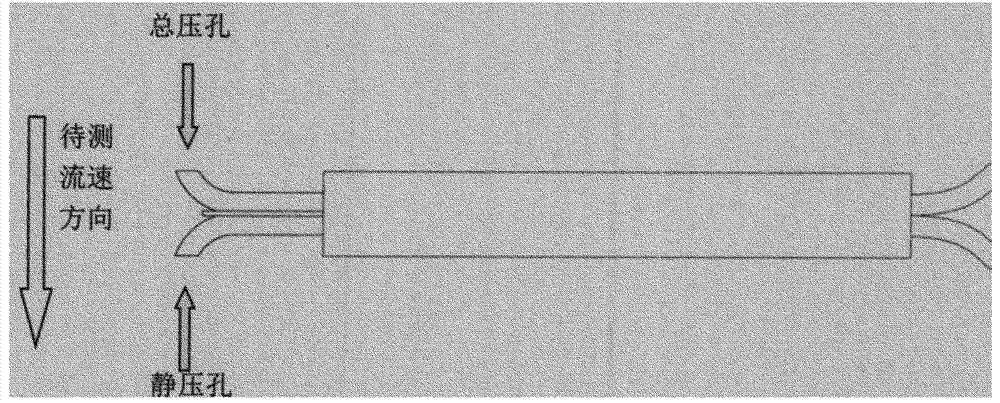

[0039] The Pitot tube flowmeter or flowmeter which is not affected by the non-measurement direction flow velocity (transverse flow velocity) of the present invention measures two pressure values, using the pressure average value of one hole or a plurality of connected holes or a plurality of disconnected holes Measure the total pressure of the fluid (for different shape designs, this pressure value is not necessarily equal to the total pressure), and use the average pressure of another hole or multiple connected holes or multiple disconnected holes to measure the hydrostatic pressure (for different The shape design...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com