Fin-cooled motor for BCP pump

A self-heating, pump-use technology, applied in the direction of electrical components, electromechanical devices, electric components, etc., can solve the problems that cannot be fully realized, and achieve the effect of saving power costs and improving service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] In order to have a further understanding and understanding of the structural features of the present invention and the achieved effects, the preferred embodiments and accompanying drawings are used for a detailed description, as follows:

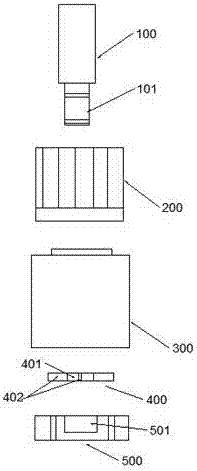

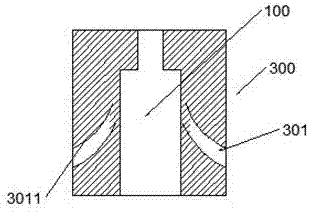

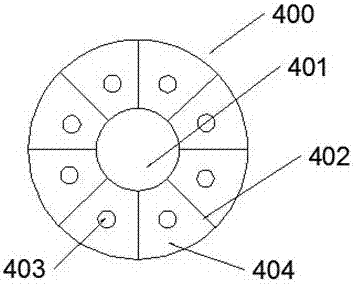

[0015] as attached Figure 1~4 As shown, a self-radiating motor for a BCP pump includes a stator 200, a rotor 100, and an outer cover 500. A drive shaft 101 is provided in the center of the inner shaft of the rotor 100, and the stator 200 is provided on the periphery of the rotor 100. The rotor 200, the drive shaft 101 and the stator 200 are coaxially arranged, and the stator 200 is provided with a motor casing 300, and the motor casing 300 is provided with an air guide port 301 communicating with the rotor 100; the air guide port The inner wall of 301 is a high-temperature-resistant ceramic coating 3011; the mass parts of the high-temperature-resistant ceramic coating 3011 are: 20-25 parts of silicon carbide, 20-26 parts of aluminum ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com