Differential-free system for roving frame

A roving frame, servo motor technology, applied in textiles and papermaking, etc., can solve the problems of troublesome maintenance and replacement, oil leakage from seal damage, low work efficiency, etc., and achieves convenient and simple production, installation and maintenance, reliable work, and reduced labor skills. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

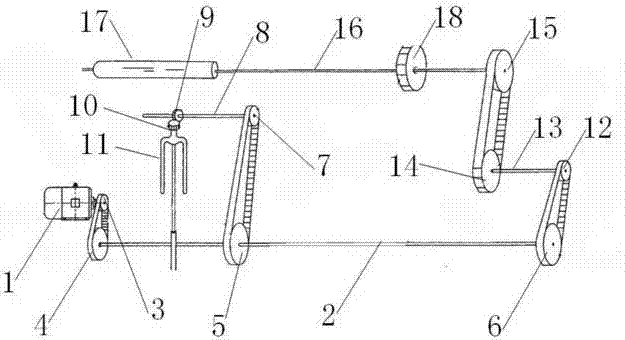

[0029] Such as figure 1 As shown, a non-differential speed system for a roving frame according to the present invention includes a motor (1) and a main shaft (2), the motor (1) is provided with a main output pulley (3), and the main output pulley (3) Connect the driving pulley (4) by 8M synchronous belt;

[0030] The main driven pulley (4) is fixed on the main shaft (2), and the main shaft (2) is provided with a first driven pulley (5) and a second driven pulley (6);

[0031] The first driven pulley (5) is connected to the third pulley (7) through an 8M synchronous belt, and the third pulley (7) is arranged on the flyer drive shaft (8), and the flyer drive shaft (8) The first gear (9) is fixedly arranged, and the first gear (9) is meshed with the second gear (10), and the second gear (10) is connected to the roving wing spindle (11);

[0032] The second driven pulley (6) is connected to the first intermediate pulley (12) through an 8M synchronous belt, the first intermediate...

Embodiment 2

[0043] Such as figure 1 As shown, a non-differential speed system for a roving frame according to the present invention includes a motor (1) and a main shaft (2), the motor (1) is provided with a main output pulley (3), and the main output pulley (3) Connect the driving pulley (4) by 8M synchronous belt;

[0044] The main driven pulley (4) is fixed on the main shaft (2), and the main shaft (2) is provided with a first driven pulley (5) and a second driven pulley (6);

[0045] The first driven pulley (5) is connected to the third pulley (7) through an 8M synchronous belt, and the third pulley (7) is arranged on the flyer drive shaft (8), and the flyer drive shaft (8) The first gear (9) is fixedly arranged, and the first gear (9) is meshed with the second gear (10), and the second gear (10) is connected to the roving wing spindle (11);

[0046] The second driven pulley (6) is connected to the first intermediate pulley (12) through an 8M synchronous belt, the first intermediate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com