Novel claw type break valve

A claw-type, pull-off valve technology, applied to valve details, safety valves, balance valves, etc., can solve the problems of difficult reset operation, high manufacturing cost, complex structure, etc., and achieve a practical and compact structure, easy operation, medium cut reliable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention is further described in conjunction with the following examples.

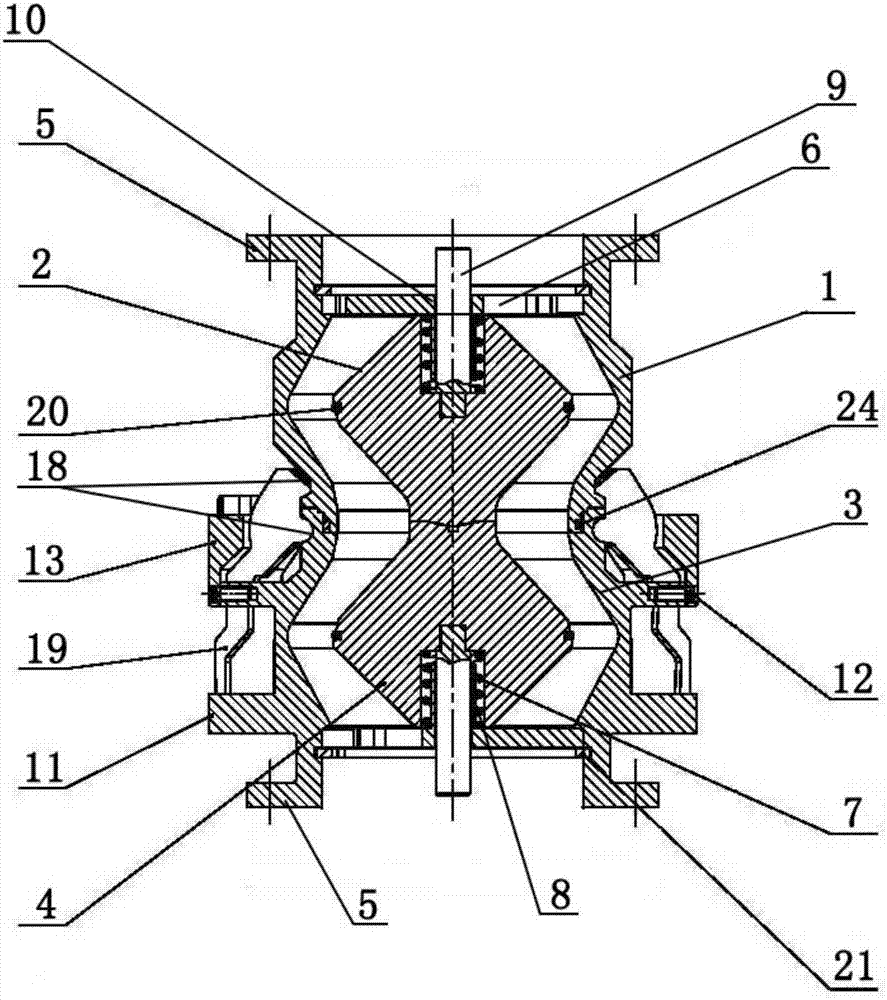

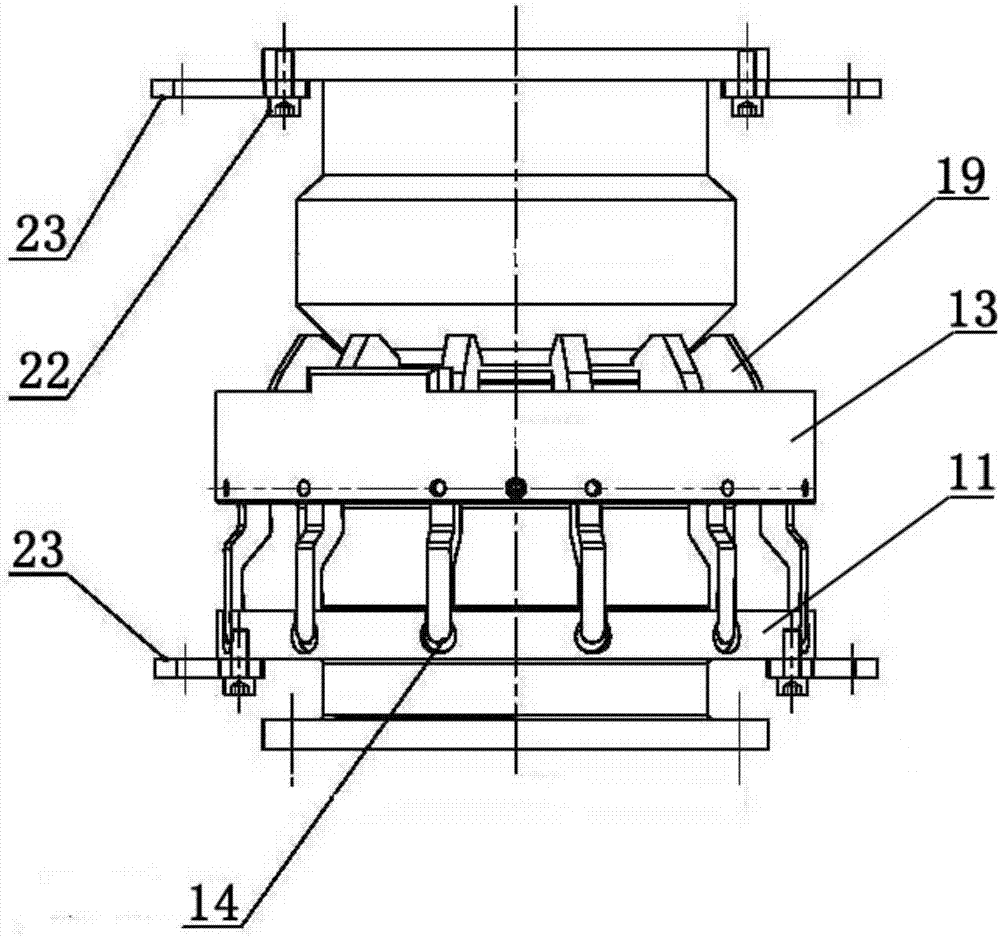

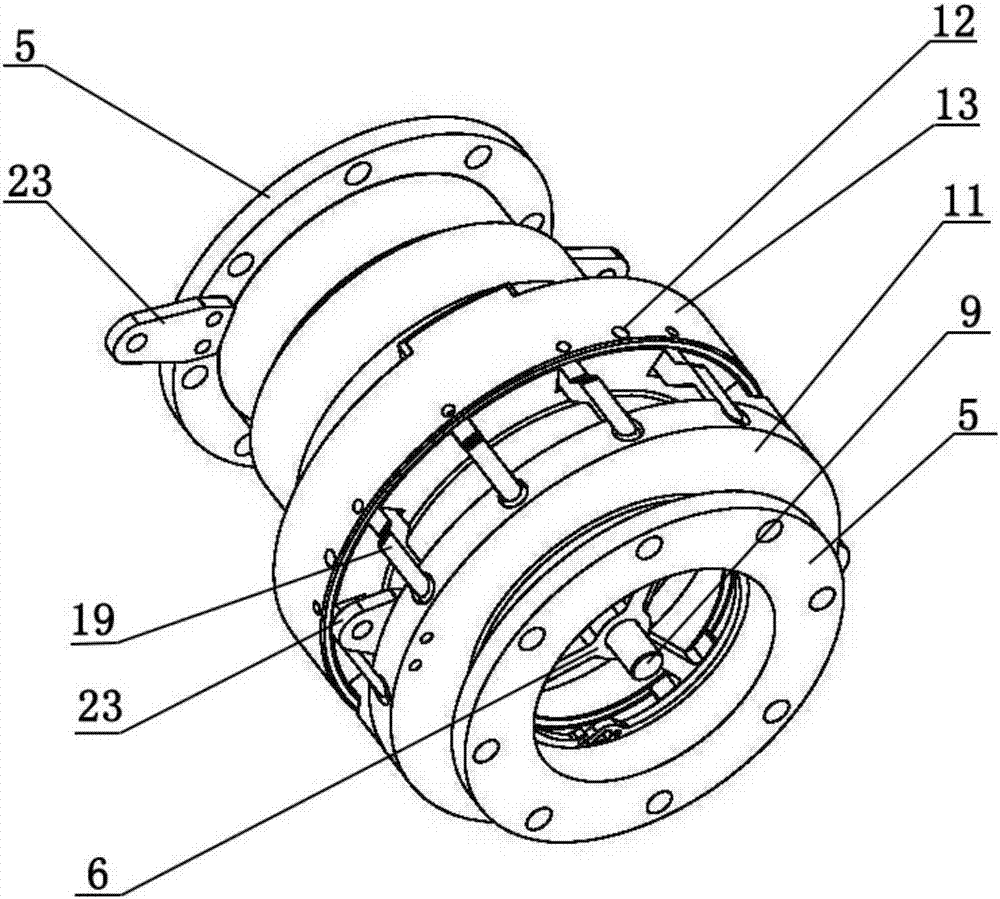

[0021] See eg Figure 1-3 A new claw-type pull-off valve is shown, including a first valve body 1, a first valve core 2, a second valve body 3 and a second valve core 4, and the first valve body 1 and the second valve core that are engaged with each other The valve body 3 is connected with the fluid pipeline through flanges 5 at both ends. The outer ends of the first valve body 1 and the second valve body 2 are fixed with a positioning plate 6, the side of the first valve core 2 and the second valve core 3 close to the positioning plate 6 is provided with a spring groove 7, and the spring groove 7 is placed There is a compression spring 8 , and the compression spring 8 passes through a positioning column 9 affixed to the first valve core 2 or the second valve core 4 , and the positioning column 9 passes through the positioning hole 10 on the positioning disc 6 . The setting of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com