Horizontal band saw cutting machine

A saw cutting machine and horizontal technology, applied in the field of horizontal segmented band saw cutting machines, can solve the problems of high cost, large material loss, complicated equipment debugging, etc., to reduce loss, reduce material loss rate, and compact structure. practical effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

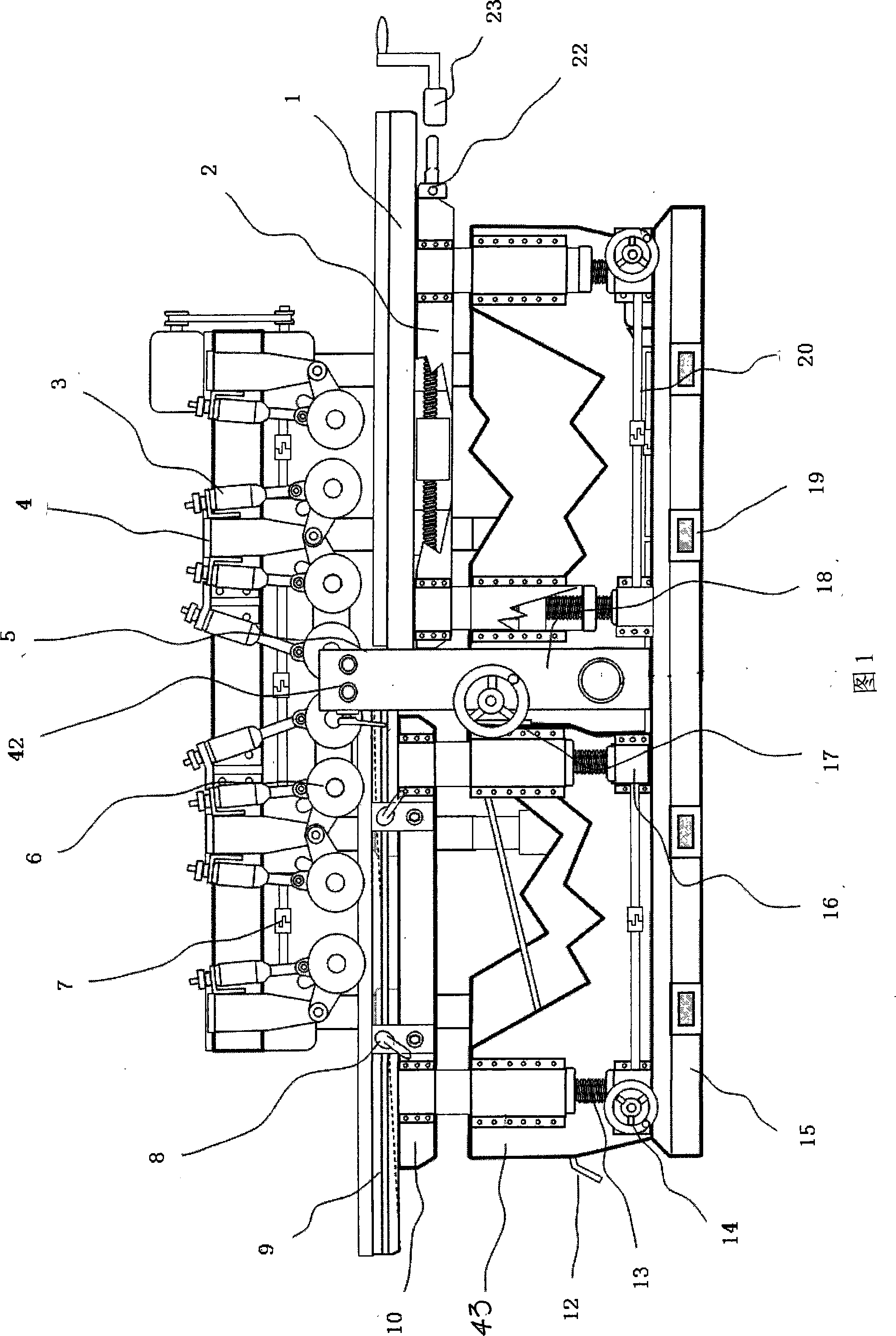

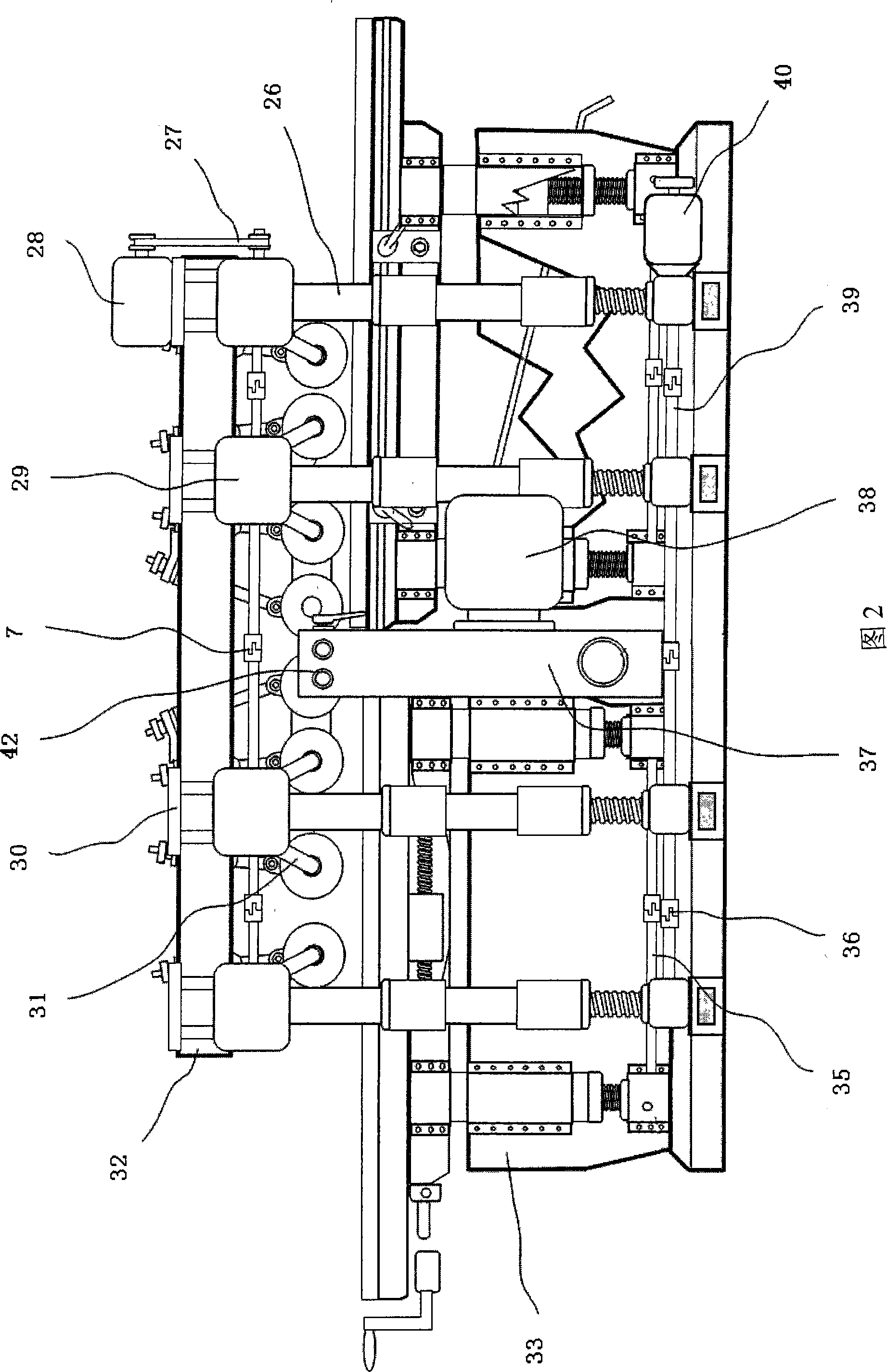

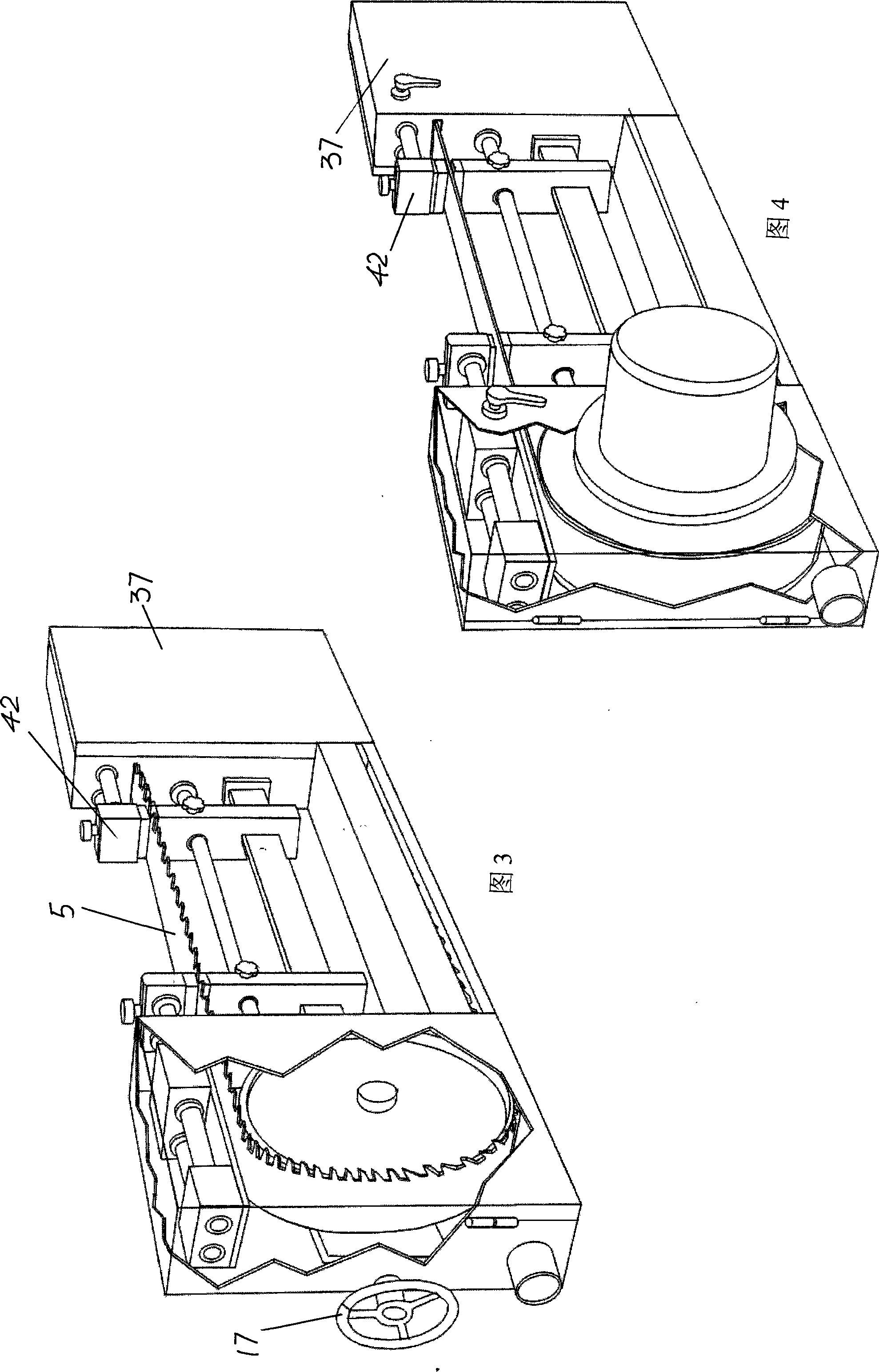

[0012] The present invention mainly includes a chassis 15 and front and rear bases 33, 43 arranged on the chassis, and is characterized in that a cutting device is embedded between the front and rear bases, and two The saw wheel is connected by a band saw blade 5, and the front and rear bases on both sides of the cutting device are respectively provided with front and rear workbench bases 2,10, respectively on the front and rear workbench bases. There are slidable workbench 1 before feeding and workbench 9 after discharge. The working surface of the band saw blade is kept at the same level as the workbench after discharge. Equipped with conveying device. The lifting pillar of the conveying device is connected to the chassis by a base crossbeam 19, and the crossbeam of the base can stably maintain the level of the conveying pressure roller and the workt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com