Electric valve and assembly method thereof

A technology of electric valves and spools, applied in the direction of valve devices, valve operation/release devices, valve lifts, etc., to achieve the effect of suppressing size deviation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

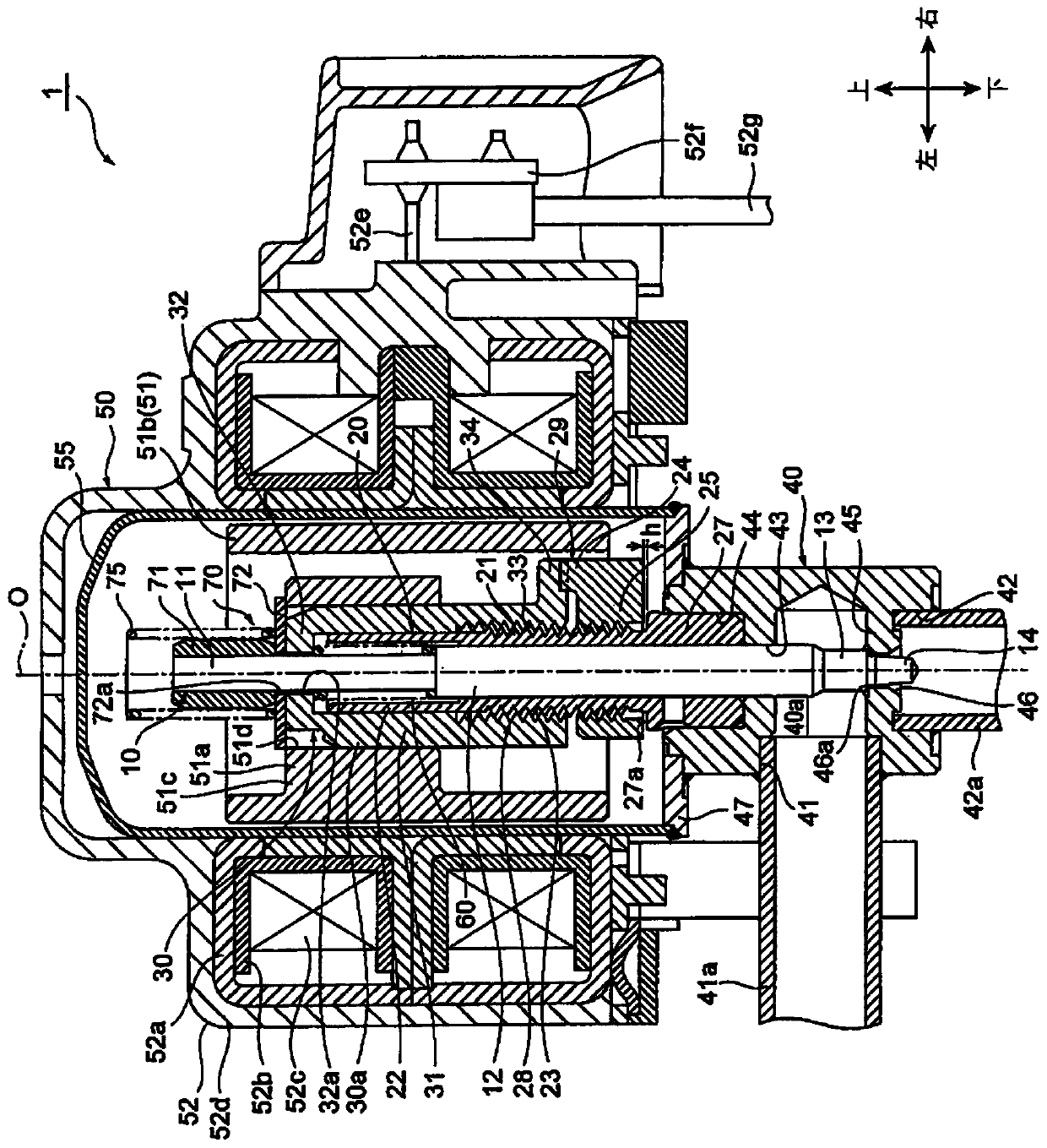

[0064] Hereinafter, specific embodiments of the electric valve and its assembly method according to the present invention will be described with reference to the drawings. In addition, in order to facilitate understanding of the invention and in consideration of drawing convenience, in each figure, gaps formed between components and separation distances between components may be exaggeratedly drawn. In addition, in this specification, it indicates positions such as up and down, left and right, and the description of directions is based on figure 1 The direction arrows in the middle indicate the reference, not the position and direction in the actual use state.

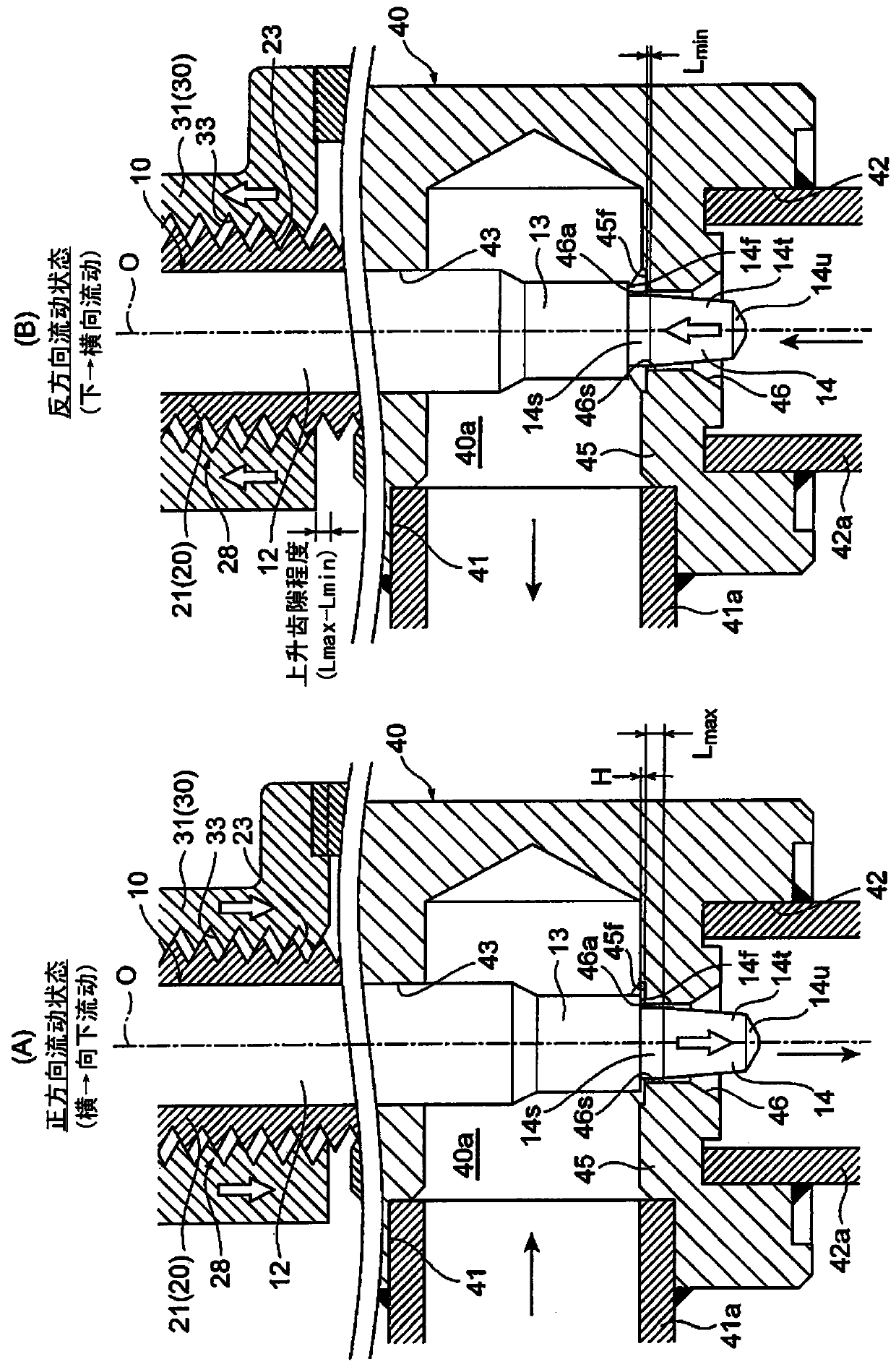

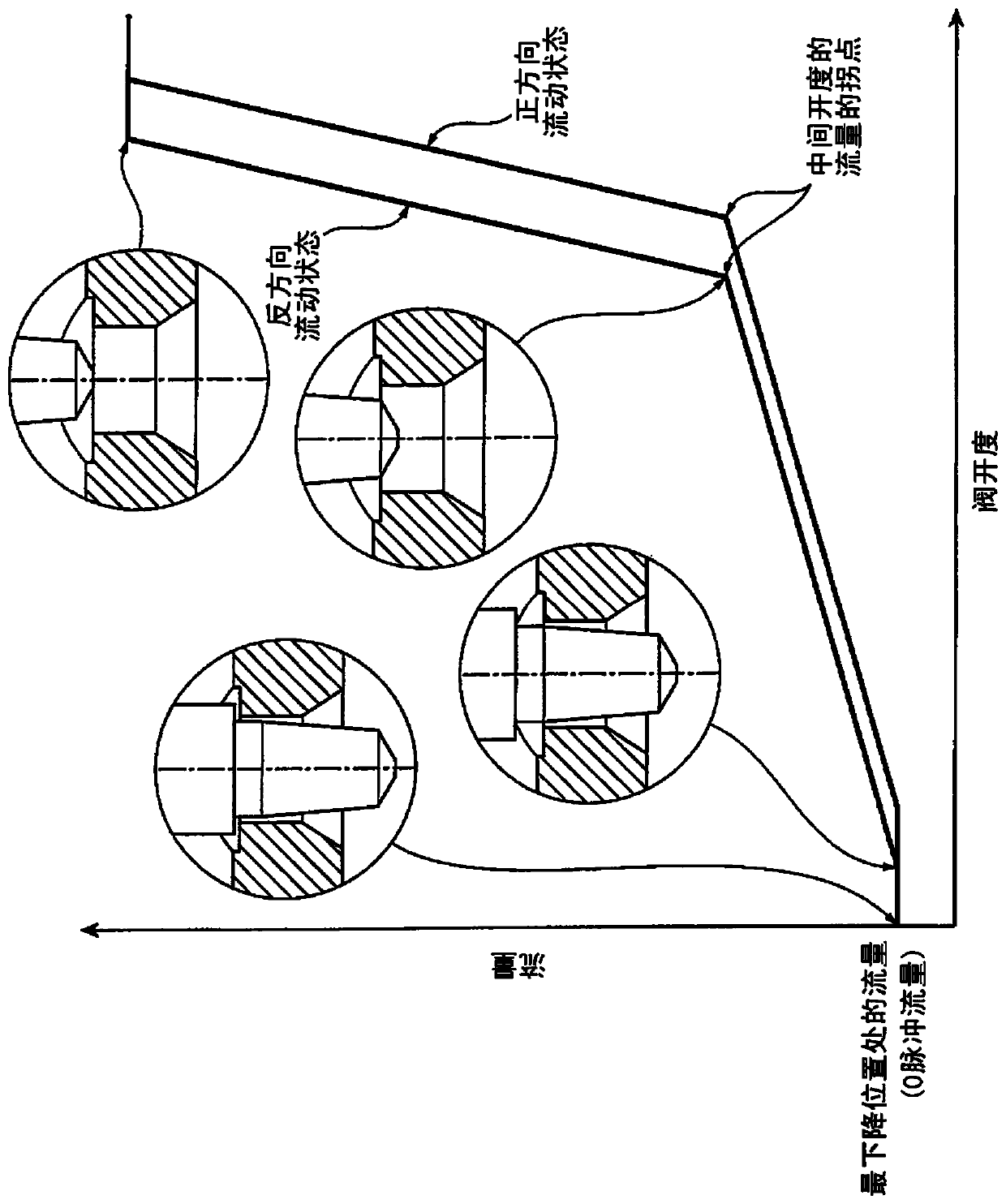

[0065] Also, in this specification, the direction from the first conduit to the second conduit via the valve chamber and the valve port orifice is taken as the "positive direction", and the direction from the second conduit to the first conduit via the valve port orifice and the valve chamber is taken as the "positive...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com