An electronic combination lock touch panel assembly process

An electronic password lock and touch panel technology, which is applied in the fields of electrical digital data processing, instruments, calculations, etc., can solve problems such as easy loosening of the touch panel, low production efficiency, reduced service life and safety of the electronic password lock, and achieve light guide Uniform and stable, improve production efficiency, easy to unlock the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with accompanying drawing:

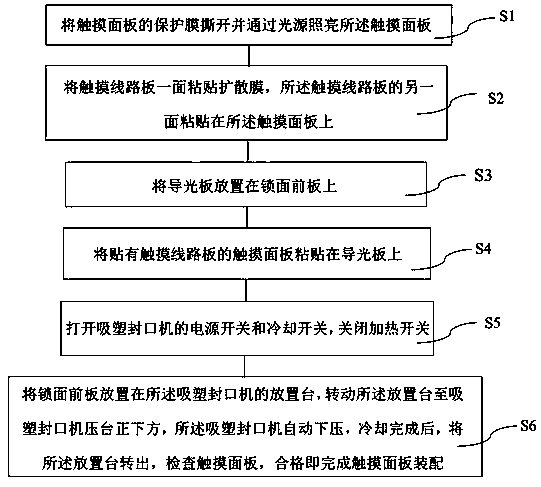

[0024] Such as figure 1 As shown, a kind of electronic combination lock touch panel assembly process proposed by the present invention comprises the following steps:

[0025] S1, take a touch panel with a good appearance, tear off the protective film of the touch panel, and illuminate the touch panel through a light source, so that the numbers on the panel can be clearly distinguished, preventing the number on the touch panel from being blocked when the touch circuit board is pasted on the touch panel, So that the numbers on the touch panel are unclear and affect the user to unlock.

[0026] S2, take the diffusion film and paste it on the touch circuit board, the holes of the touch circuit board are all covered, and the edges are neat, the diffusion film includes a base material layer and two diffusion layers, the base material layer is coated with optical astigmatism part...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com