Analysis method for critical rotational speed of rotor based on probability box frame

A critical speed and analysis method technology, applied in special data processing applications, instruments, electrical digital data processing, etc., can solve problems that cannot reflect the physical structure, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

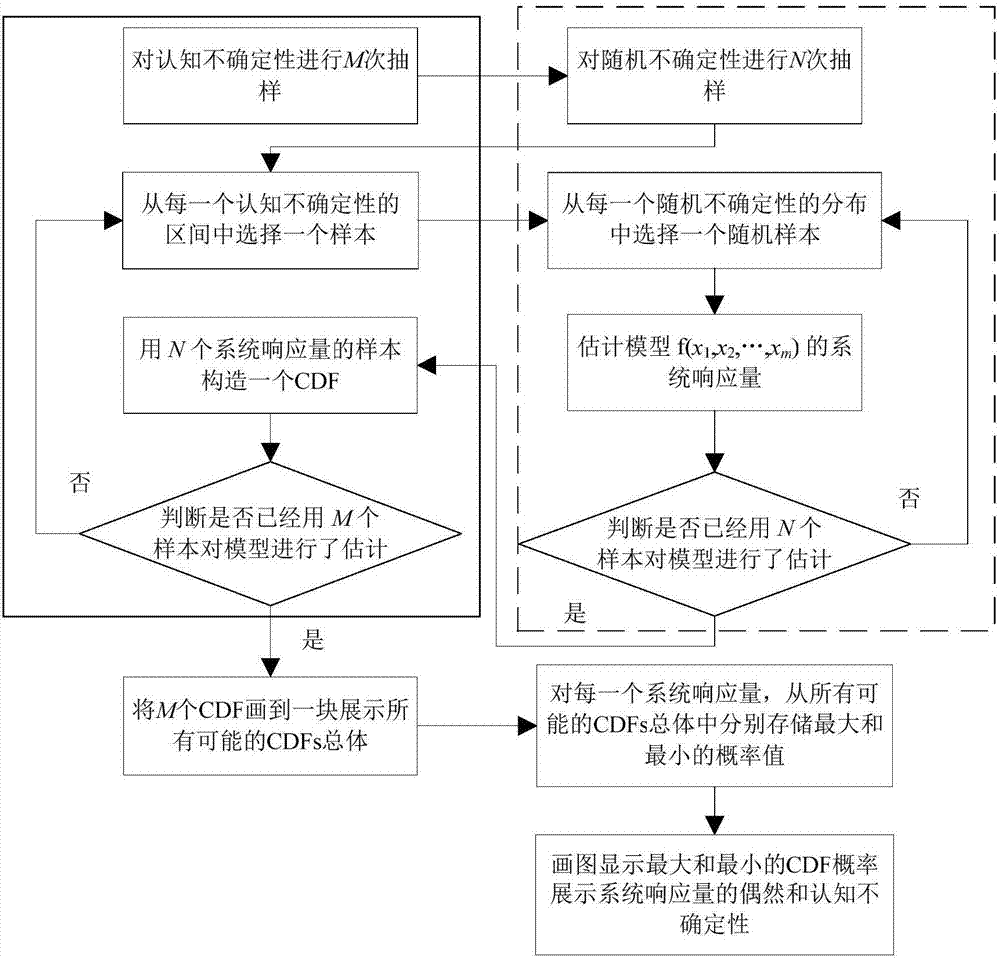

[0069] The specific implementation steps of critical speed analysis include:

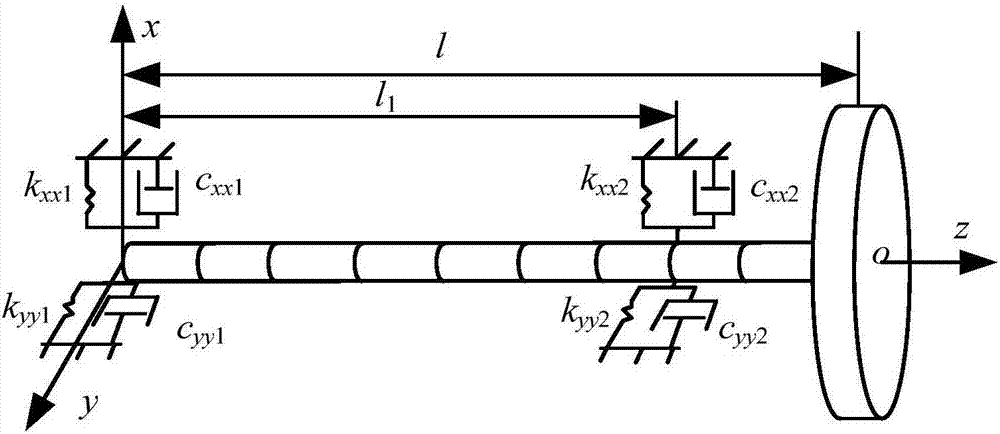

[0070] 1. Transformation of rotor support. exist figure 1 In the illustrated embodiment, each rotor support is shown with spring rates and damping in both directions, respectively.

[0071] 2. The finite element model of the bearing-rotor system is established by using the commercial finite element software Patran and Nastran. Consider an asymmetric single disc bearing-rotor system (xyz) such as figure 1 As shown, l 1 =2.40m, is the distance between two bearings; l=3.0m, is the total length of the rotor; k xx1 , c xx1 , k yy1 , c yy1 ; k xx2 , c xx2 , k yy2 , c yy2 are the radial stiffness and damping parameters of the two bearings, respectively. figure 1 Among them, the diameter of the rotor is d=0.16m, the initial value of the elastic modulus of the rotor material is E=210GPa, and the density is 7850kg / m 3 , Poisson's ratio 0.3. The diameter of a single disc is 1.5m and the thickness...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com