Doping type lithium battery anode material

A technology of positive electrode materials and doped materials, which is applied to battery electrodes, circuits, electrical components, etc., can solve problems such as insufficient capacity, decreased battery discharge capacity, and low voltage, and achieve the effect of improving working time and service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

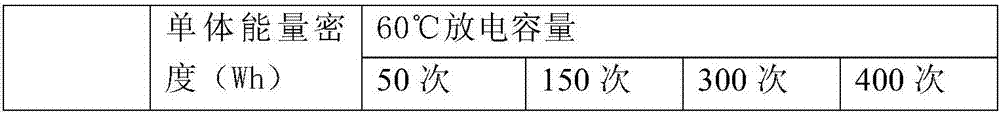

Image

Examples

Embodiment 1

[0015] The anode material of the doped lithium battery of the present invention is composed of the following components: 92wt% ternary material and 8wt% doping material.

[0016] In the ternary material: the weight ratio of lithium nickelate, lithium manganate and lithium cobaltate is 1:0.5:0.5.

[0017] The doping material is a mixture of ferrous sulfide and manganese sulfide, wherein the weight ratio of the ferrous sulfide to the manganese sulfide is 1:4.

Embodiment 2

[0019] The positive electrode material of the doped lithium battery of the present invention is composed of the following components: 93wt% ternary material and 7wt% doping material.

[0020] In the ternary material: the weight ratio of lithium nickelate, lithium manganate and lithium cobaltate is 1:0.75:0.75.

[0021] The doping material is a mixture of ferrous sulfide and manganese sulfide, wherein the weight ratio of the ferrous sulfide to the manganese sulfide is 1:1.

Embodiment 3

[0023] The anode material of the doped lithium battery of the present invention is composed of the following components: 94wt% ternary material and 6wt% doping material.

[0024] In the ternary material: the weight ratio of lithium nickelate, lithium manganate and lithium cobaltate is 1:0.6:0.9.

[0025] The doping material is a mixture of ferrous sulfide and manganese sulfide, wherein the weight ratio of the ferrous sulfide to the manganese sulfide is 4:1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com