Production method of a strip steel split tension leveling coil inspection unit

A production method and subdivision technology, applied in the direction of manufacturing tools, metal rolling, metal rolling, etc., can solve the problems of large investment, inability to include the complete function of the finishing unit, and inability to complete the finishing production, etc., to achieve improvement The effect of utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0058] The present invention will be further described in detail below in conjunction with specific embodiments, which are explanations of the present invention rather than limitations.

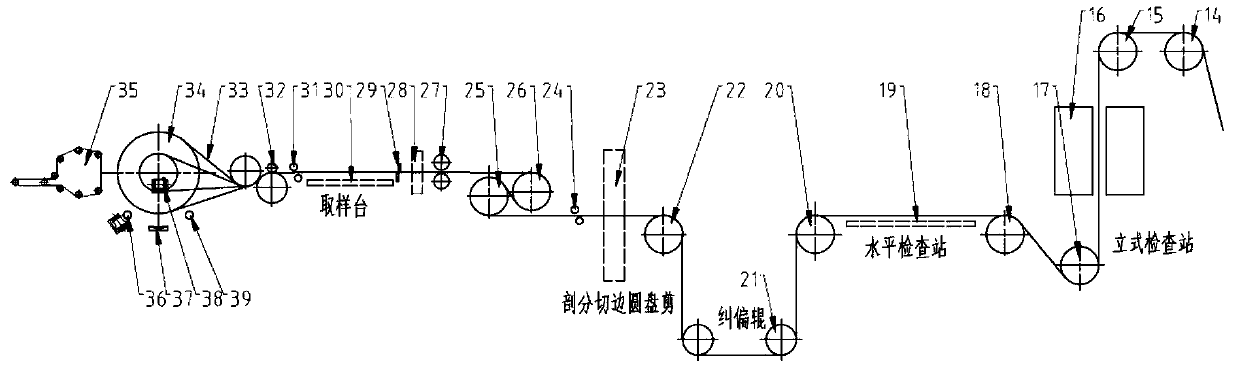

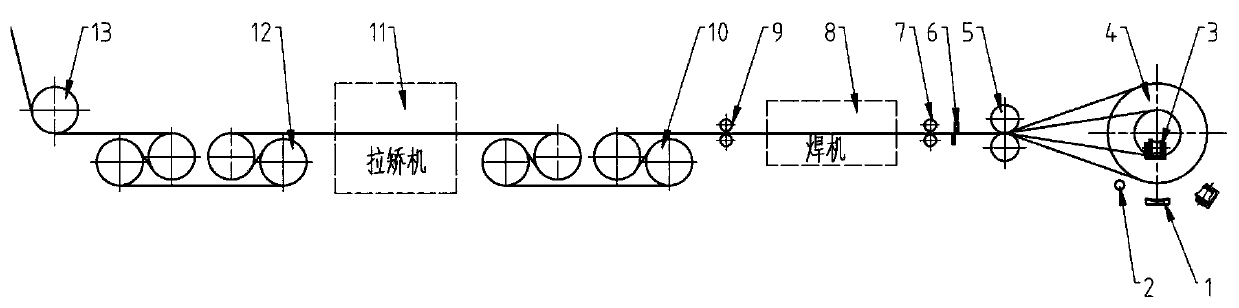

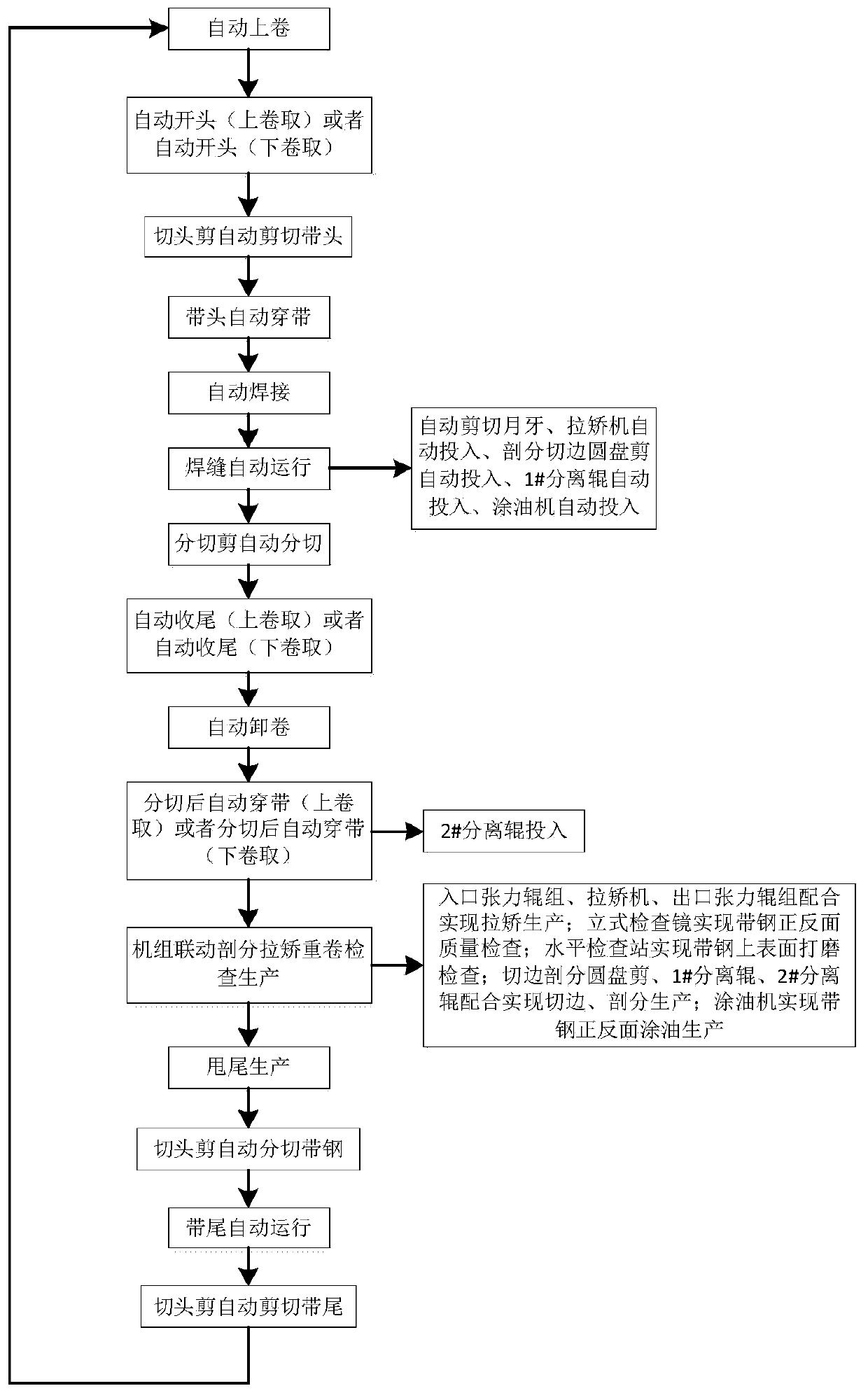

[0059] The production method of the strip steel splitting, tensioning and weighting coil inspection unit provided by the present invention is completed by the equipment shown in Figure 1, and the equipment along the line includes a coiling trolley 1, an uncoiling lower pressure roller 2, an uncoiling shaft head support 3, and an uncoiler 4 , Opening machine 5, head cutting shear 6, pinch roller before welding 7, welding machine 8, pinch roller after welding 9, entrance tension roller group 10, tension leveler 11, exit tension roller group 12, vertical inspection station No. One turning roller 13, the second turning roller 14 of the vertical inspection station, the third turning roller 15 of the vertical inspection station, the vertical inspection mirror 16, the fourth turning roller 17 of the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com