Acrylic board model machining device

A processing device, acrylic sheet technology, applied in the direction of flat products, household appliances, other household appliances, etc., can solve the problem of not being unique enough, and achieve the effect of convenient molding, strong expansibility, and enhanced use value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

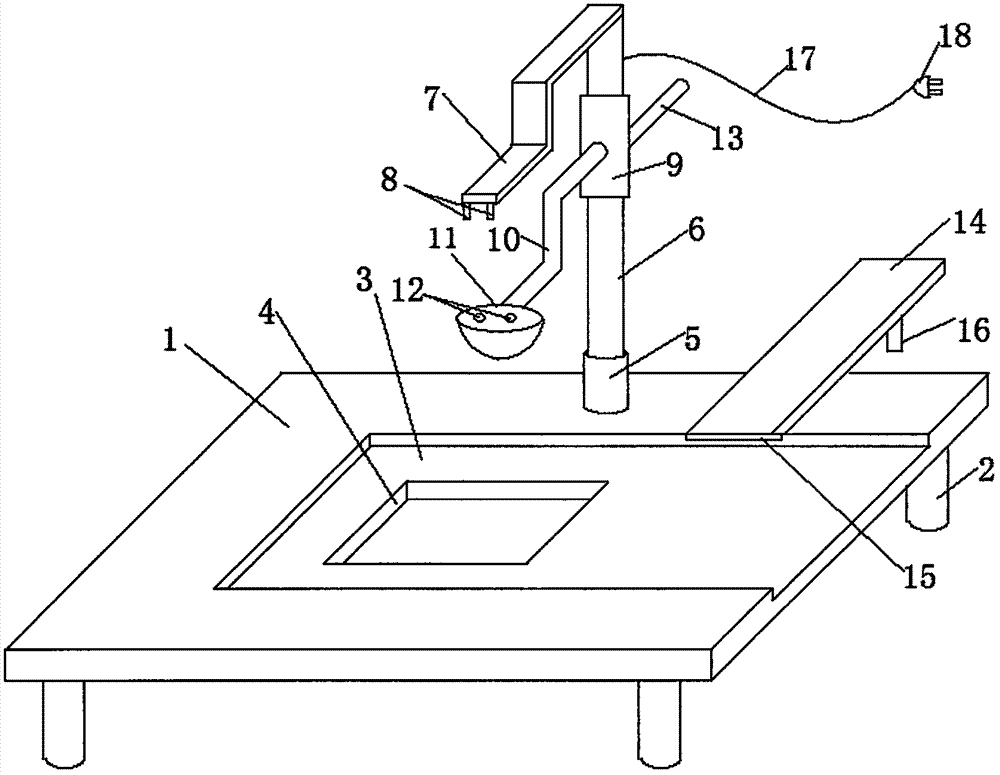

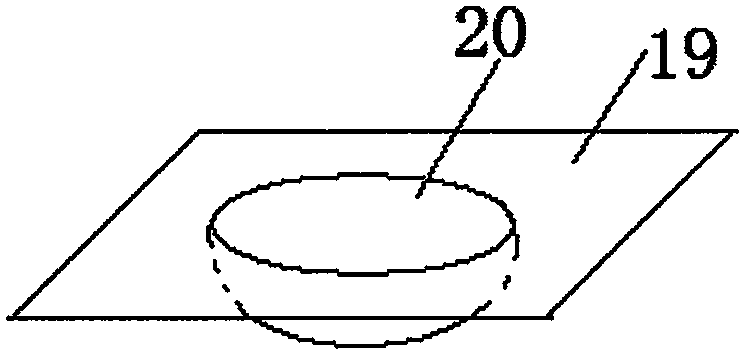

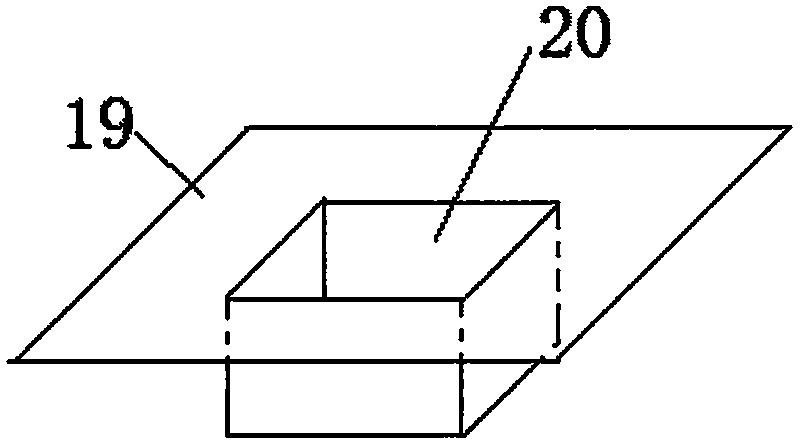

[0017] Comply with the above technical solutions, such as Figure 1 to Figure 3 As shown, the present invention discloses a molding and processing device for an acrylic plate, which includes a bottom plate 1, a bracket 2 is distributed on the bottom of the bottom plate 1, a processing groove 3 is opened on the upper surface of the bottom plate 1, and one end of the processing groove 3 passes through one of the bottom plate 1. Side; the processing groove 3 is provided with a through groove 4 that runs through the bottom surface of the bottom plate 1, and the through groove 4 is detachably equipped with a template 19, and the template 19 is provided with a model groove 20; the top of the bottom plate 1 is provided with a metal material, or the indenter 11 of a material that is easy to conduct heat, and a heating wire is arranged inside the indenter 11 , and the indenter 11 can move in a direction perpendicular to the bottom plate 1 .

[0018] In the present invention, the surfac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com