Crawler unit

A walking mechanism and crawler technology, which is applied in the field of machinery, can solve the problems of not meeting the requirements of climbing and walking, derailment and overturning of the crawler belt, and low grip of the crawler belt, so as to prevent the risk of derailment and tipping of the crawler belt, and reduce vibration and impact , The effect of increased track grip

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

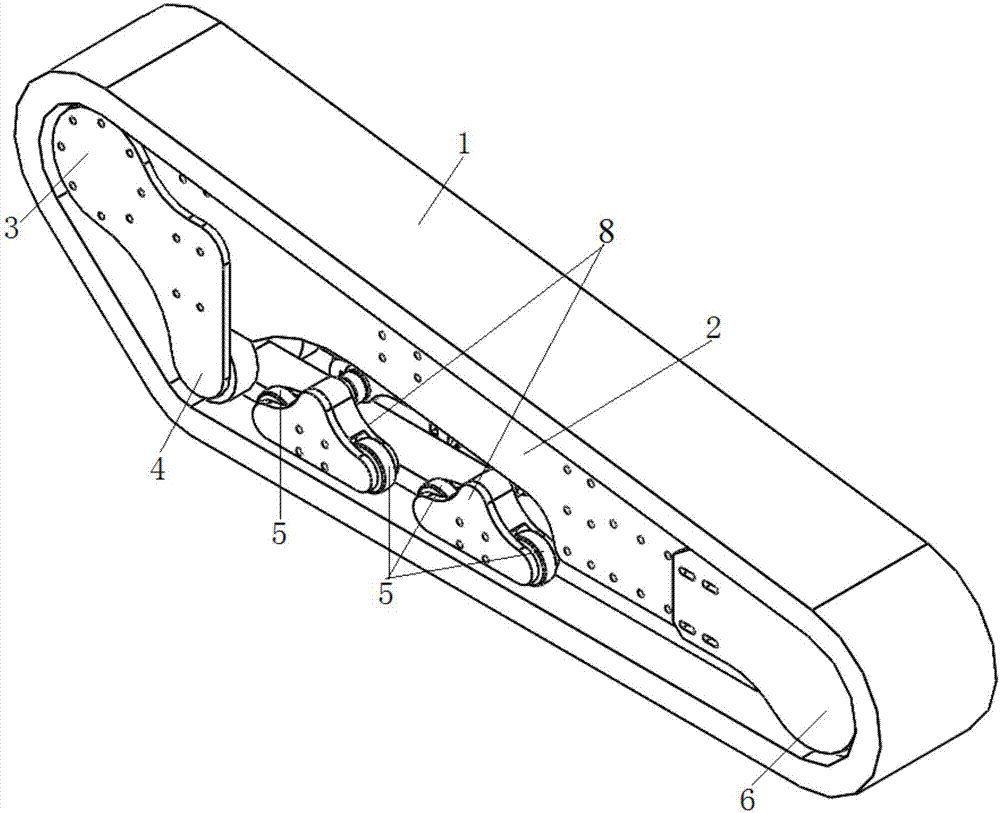

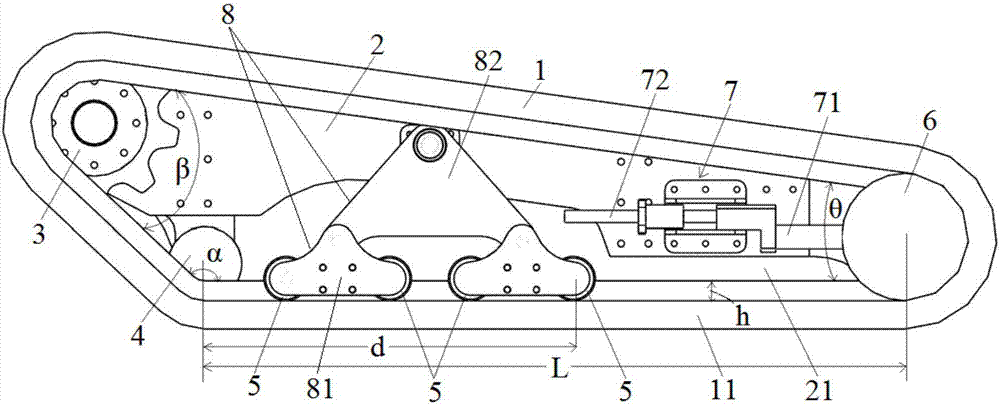

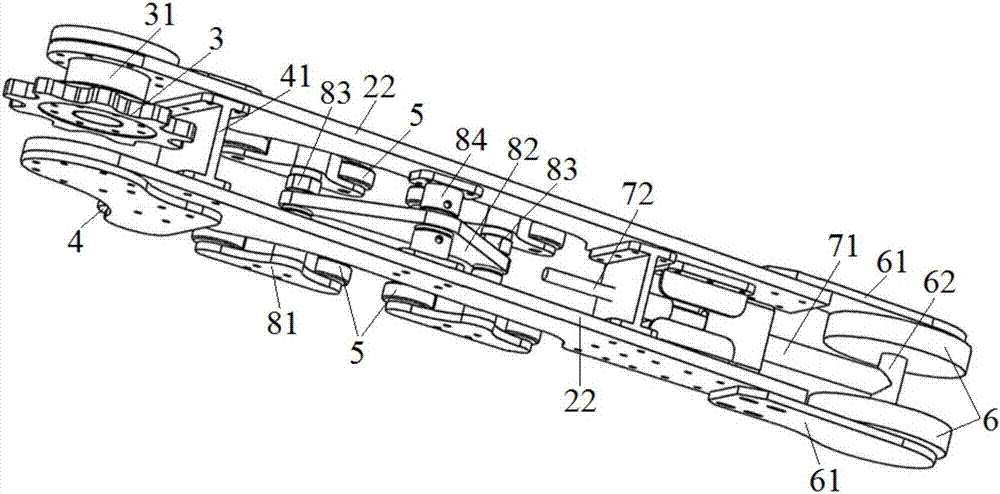

[0026] combine figure 1 and figure 2 Shown: a crawler running mechanism provided in this embodiment, including a crawler 1, a crawler beam 2, a driving wheel 3, a fixed supporting wheel 4, a floating supporting wheel 5 and a tensioning wheel 6, the driving wheel 3 Located at the front end of the track beam 2, the tension wheel 6 is located at the rear end of the track beam 2, and the fixed track roller 4 and the floating track roller 5 are located between the driving wheel 3 and the tension wheel 6, and are fixed The fixed roller 4 is located in front of the floating roller 5, and the fixed roller 4 is on the same ground plane as the floating roller 5 and the tension roller 6. The distance d between the centers of gravity of the floating rollers 5 accounts for 40% to 70% (preferably 50% to 60%) of the length L of the ground track 11, so that the overall center of gravity can move forward to the fixed rollers when climbing. 4), the track 1 surrounds the driving wheel 3, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com