Rotatable conveyor with improved structure

A technology of conveyors and turntables, which is applied to rotary conveyors, conveyors, transportation and packaging, etc., can solve the problems of high production costs and single use, and achieve the effects of saving costs, promoting health and saving resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

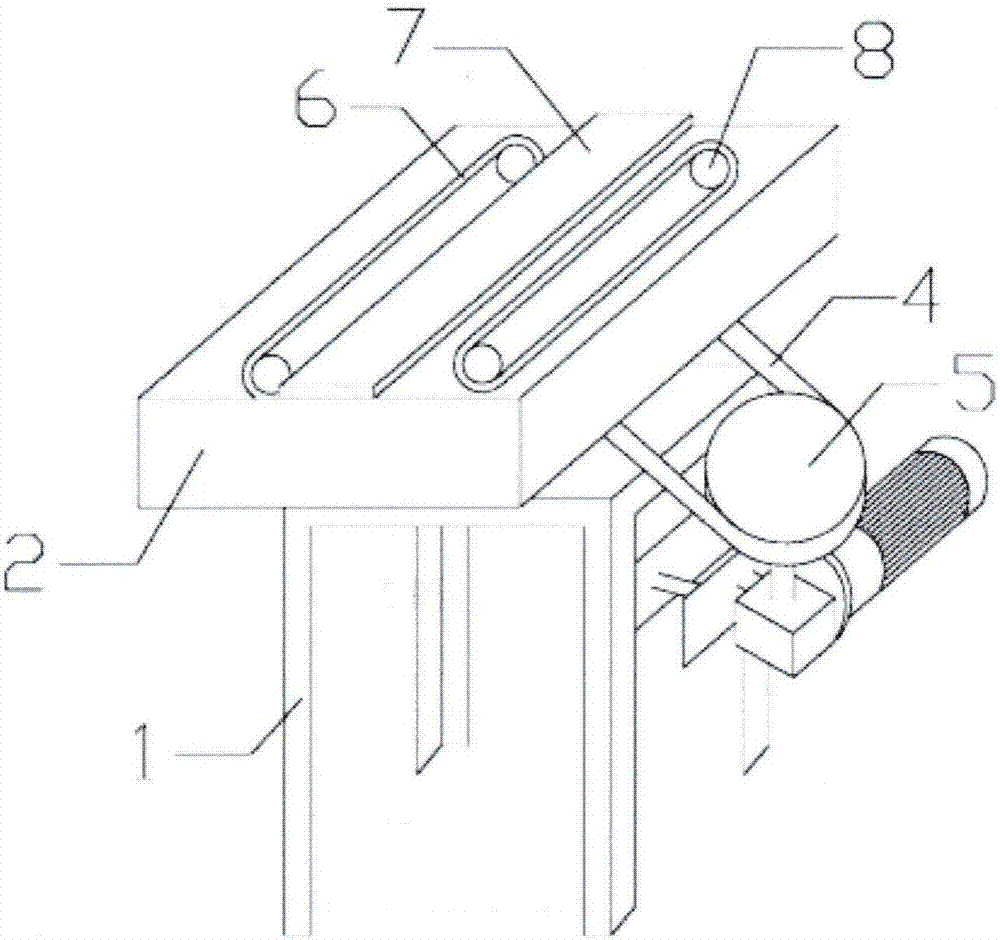

[0017] Such as Figure 1-2 As shown, a structure-improved rotatable conveyor of this embodiment includes a base 1, the base 1 is a metal platform, a delivery platform 2 is arranged on the base 1, and a delivery platform 2 is arranged between the base 1 and the delivery platform 2. There is a turntable 3, and the turntable 3 is connected to a turntable 5 through a belt 4, and a motor is connected below the turntable 5, and the turntable 5 and the motor are fixed on the side of the base 1.

[0018] The conveying platform 2 is provided with a chain 6 and a slide plate 7, and the chain 6 is connected to form a loop through the axles 8 at both ends, and the slide plate 7 is arranged between the two chains 6 for supporting during transportation. A motor is arranged on the side of the conveying platform 2, and the motor is connected to the wheel shaft 8 to drive the rotation of the chain 6, so that the goods can be transported.

[0019] The above-mentioned base 1 is provided with a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com