Negative Poisson's ratio yarn composite spinning device, method and application of pre-wrapped tube

A technology of negative Poisson's ratio and composite spinning, which is applied in spinning machine, yarn, textile and papermaking, etc., can solve the problem that it is difficult to obtain a higher negative Poisson's ratio, and achieve obvious negative Poisson's ratio effect, Easy to install effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

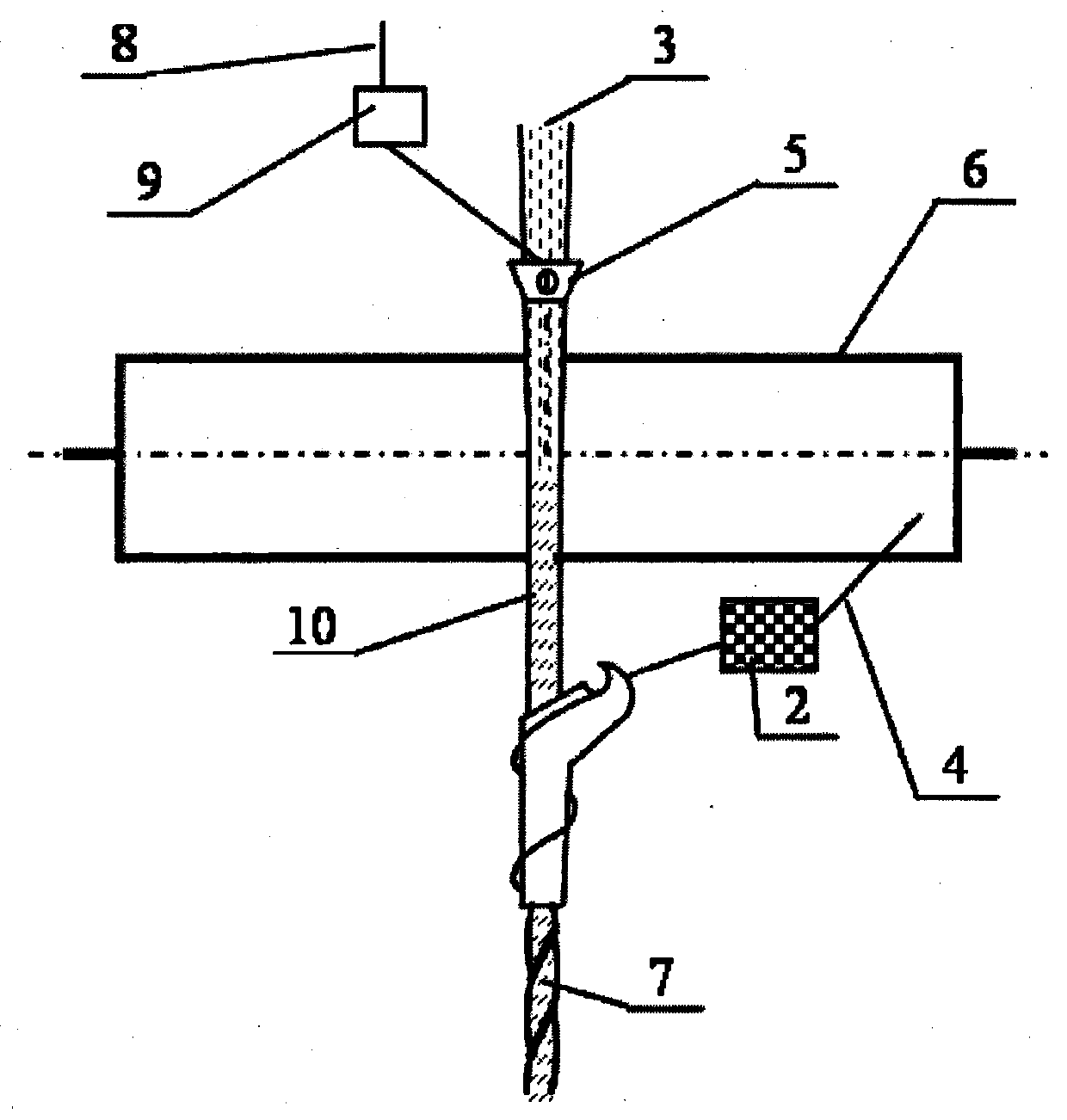

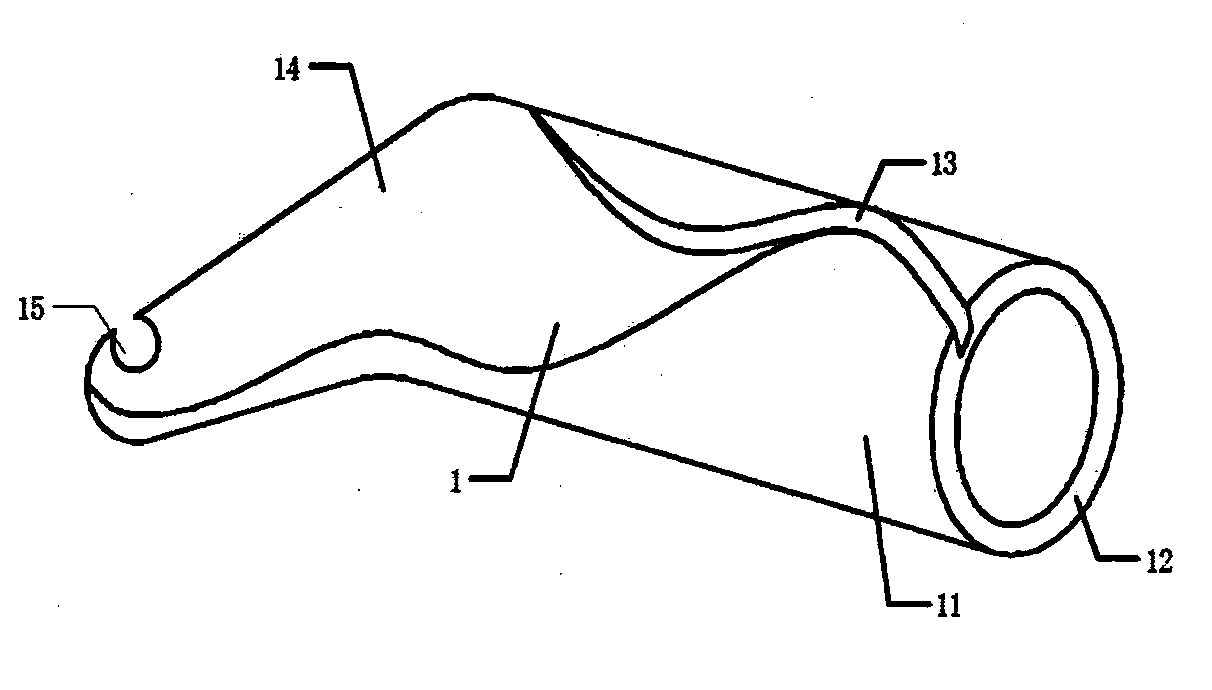

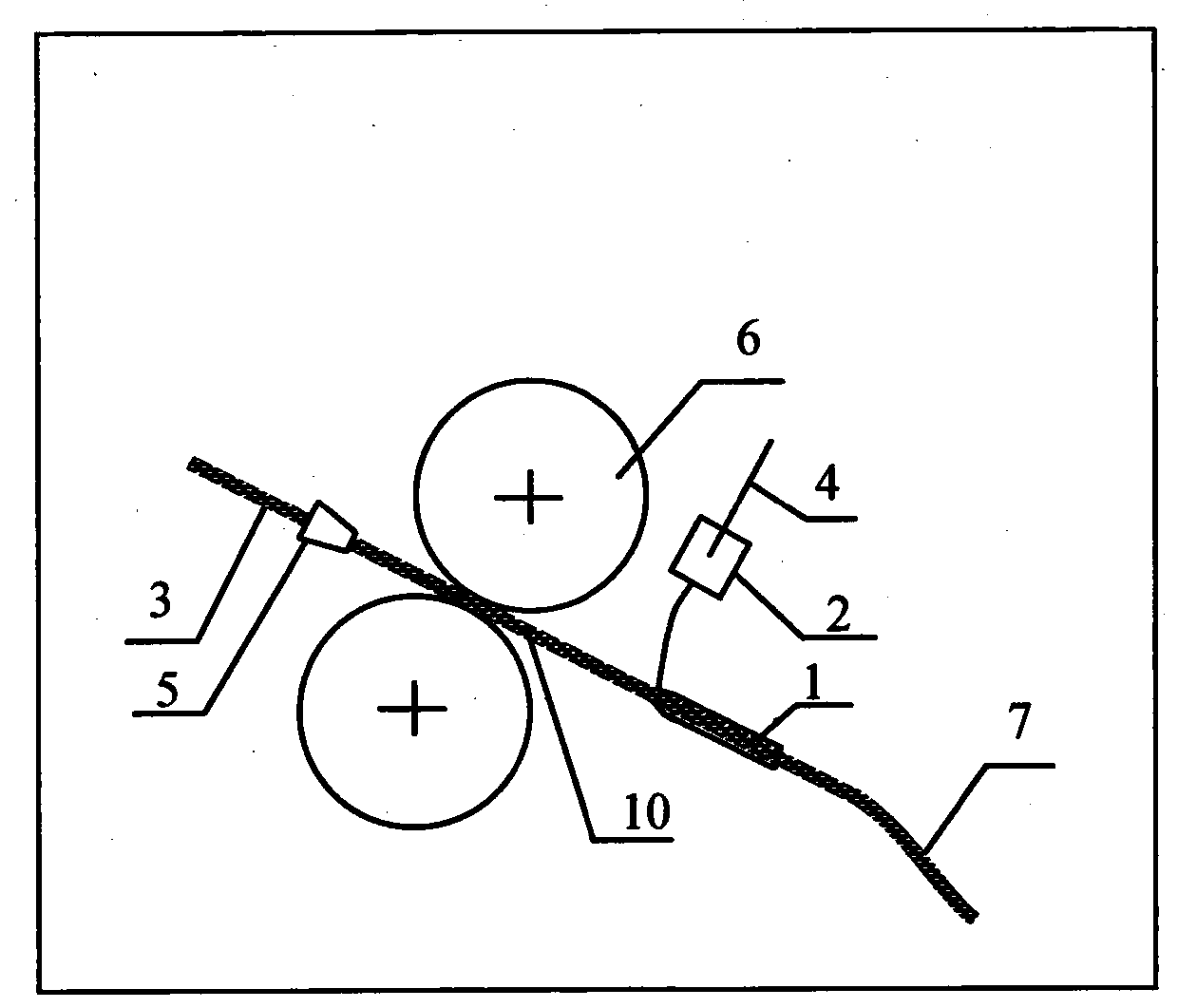

[0061] Example 1: Spinning of Nomex Staple / Kevlar Filament Composite Negative Poisson's Ratio Composite Yarn

[0062] Using the pre-wrapped tube composite spinning device of the present invention, the Kevlar filament bundles are fed into the holding roller pair of the overfeeding mechanism 2 in the above-mentioned manner, and then overfeed into the pre-wrapped tube 1, out of the pre-wrapped tube and out The yarn mouth 12 is axially converged with the Nomex sliver to be twisted to form a yarn. The specific process parameters and the measured data of the yarn are shown in the table. The physical and mechanical properties of the spun Nomex staple / Kevlar filament negative Poisson's ratio composite yarn are as follows. Among them, when the Nomex staple fiber / Kevlar filament composite yarn is stretched, the Nomex staple fiber strands change from straightening to spiral wrapping; Kevlar filament bundles change from spiral wrapping to straightening core yarn, that is, the composite ya...

Embodiment 2

[0063] Example 2: Negative Poisson's Ratio Composite Yarn of Polyester Cotton Staple Fiber + Elastane Yarn / High Strength Polyester Filament Filament

[0064] Using the pre-wrapped tube composite spinning device and process of the present invention, the elastic yarn (spandex) is fed into the holding roller pair of the overfeeding mechanism 2 in the above-mentioned manner, and then overfeeds into the pre-wrapped tube 1, and the pre-wrapped tube 1 is fed out. The yarn outlet 12 of the winding tube is axially converged with the spun polyester-cotton staple fiber sliver and twisted to form a yarn. The specific process parameters and the measured data of the yarn are shown in the table. The physical and mechanical properties of the spun (polyester-cotton staple fiber + elastic yarn) / high-strength polyester filament negative Poisson's ratio composite yarn are as follows. Among them, when the elastic core-spun yarn of polyester-cotton staple fiber and spandex yarn / high-strength polyes...

Embodiment 3

[0065] Example 3: Spinning of basalt staple fiber yarn / carbon fiber filament composite negative Poisson's ratio composite yarn

[0066] Using the above-mentioned overfeed asymmetric two-axis composite spinning device of the present invention, the carbon fiber filament bundle is fed into the holding roller pair of the overfeed mechanism 2 according to the above method, and then the overfeed enters the pre-wrap tube 1, and the pre-wrap is discharged. The yarn outlet 12 of the winding tube is axially converged with the spun basalt short fiber whiskers and twisted to form a yarn. The specific process parameters and the measured data of the yarn are shown in the table. The physical and mechanical properties of the spun basalt staple fiber / carbon fiber filament negative Poisson's ratio composite yarn are as follows. Among them, when the basalt staple fiber / carbon fiber filament composite yarn is stretched, the basalt staple fiber strands change from straight to spiral wrapping; the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com