Narrow flake composite fiber material compression molding

A narrow sheet and fiber technology, applied in the field of compression molding of narrow sheet composite fiber materials, can solve problems such as orientation changes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

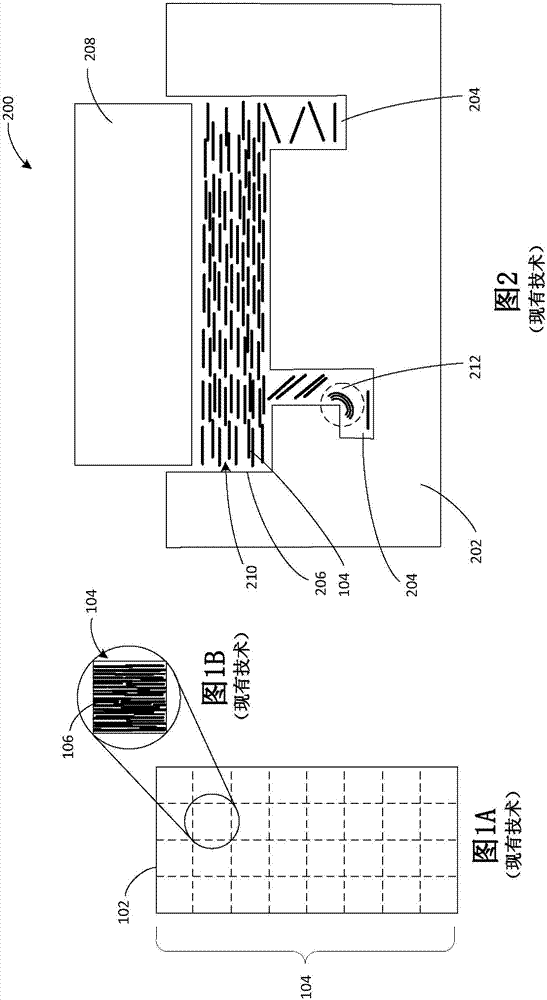

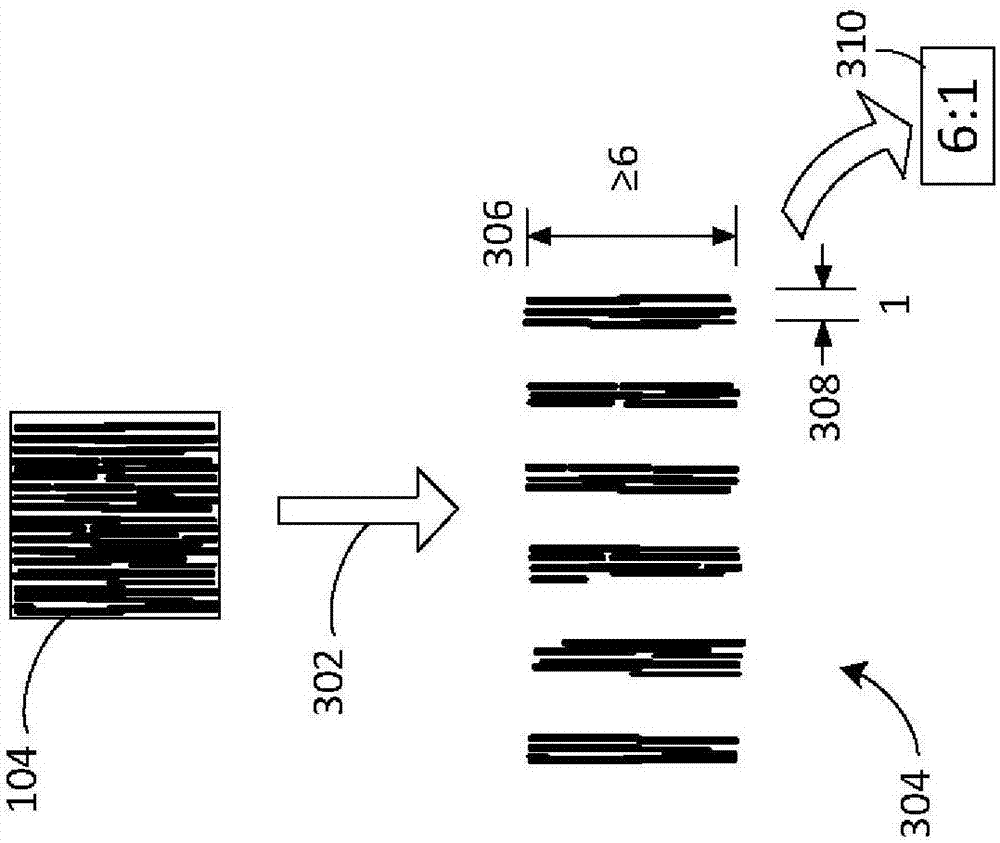

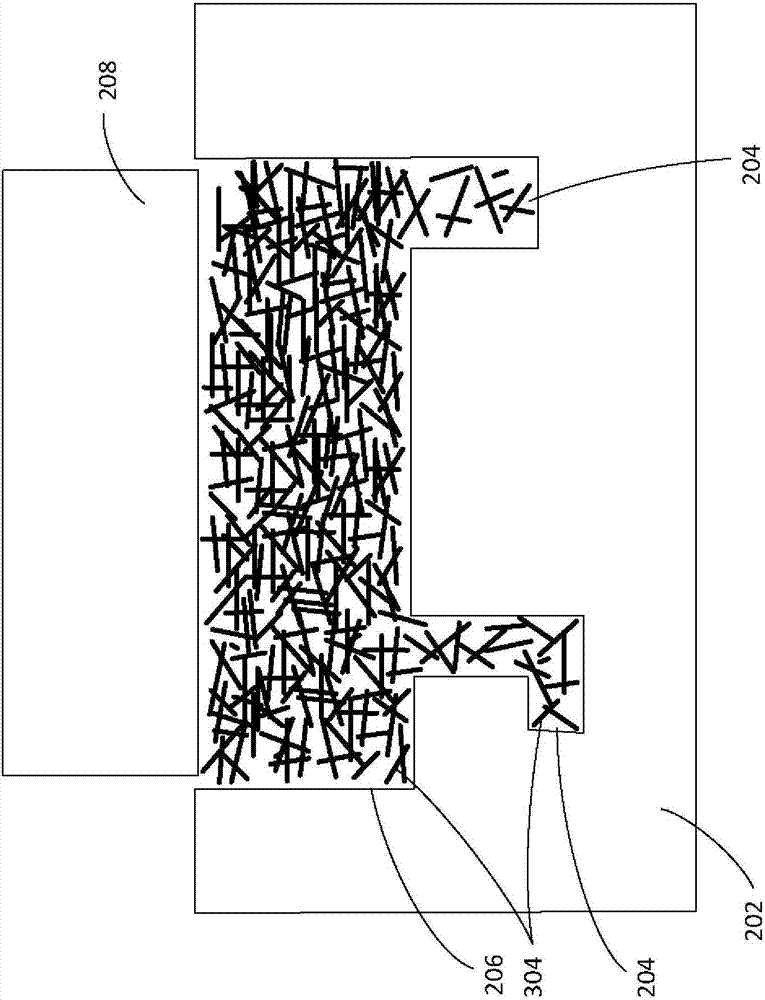

[0020] The detailed description below is directed to methods for producing three-dimensional random fiber orientations in composite components. As briefly discussed above, conventional composite assemblies made using compression molding techniques often include undesired areas of the laminate stack of composite sheets that have been pushed through the mold. The resulting assembly may include thinned regions corresponding to in-mold regions with substantially laminated stacks, particularly when these regions are subjected to shear or tensile forces during use of the composite assembly.

[0021] Utilizing the concepts described herein, composite components are fabricated in a manner that produces composite fibers with consistent, three-dimensionally random fiber orientation throughout the component. Doing so can increase the strength of the composite component, and most importantly, the strength of the component can be consistent and predictable throughout the component and all ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com