Heat exchanger and air conditioning device

A heat exchanger and heat exchange tube technology, applied in the details of space heating and ventilation, household heating, heating methods, etc., can solve the problems of impact resistance, poor vibration ability, low connection strength, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments, but not as a limitation of the present invention.

[0034] In view of this situation, the present invention provides a heat exchanger resistant to tilting, swaying, impact and vibration, especially a falling film heat exchanger.

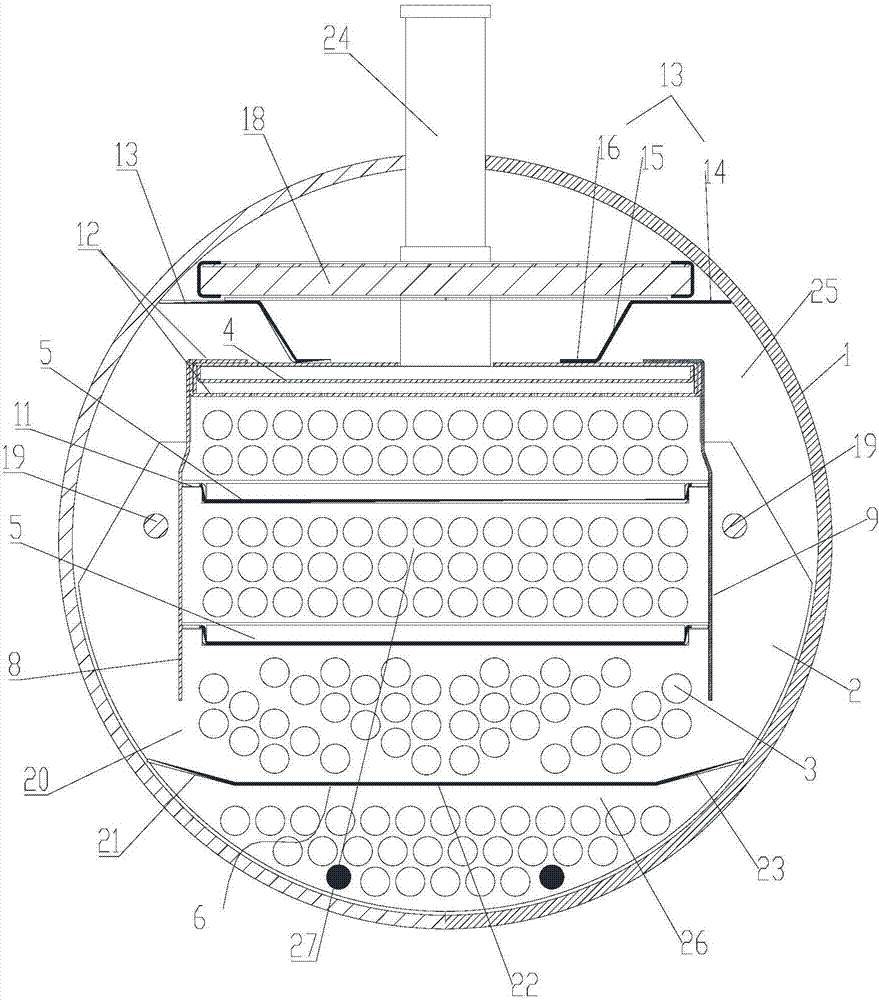

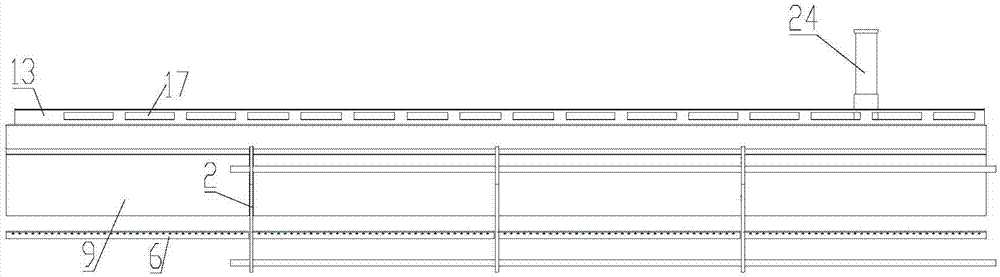

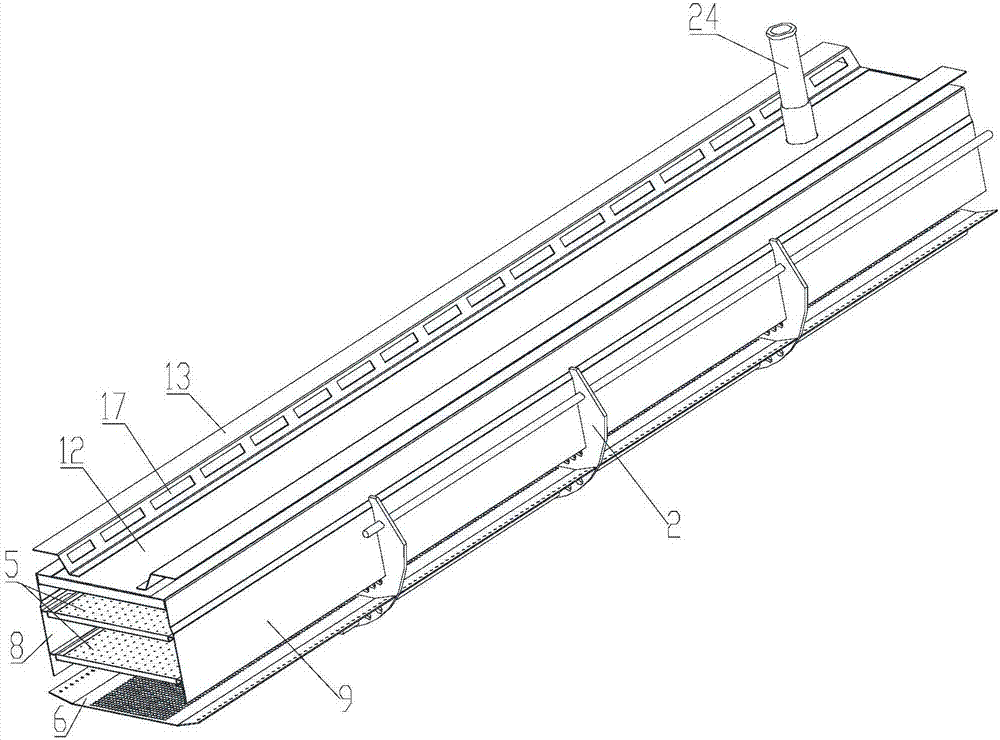

[0035] In one embodiment, the heat exchanger includes: a housing 1 and a liquid distributor assembly disposed in the housing 1, the liquid distributor assembly includes a support plate 2 and heat exchange tubes 3, the support plate The lower edge of 2 is formed into an arc matching the shape of the inner wall of the housing 1, the heat exchange tube 3 passes through the support plate 2, and the heat exchange tube 3 is connected to the housing through the arc. The contact structure between the inner walls of 1 is supported in the housing 1. Preferably, the central angle of the sector formed by the arc and the i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com