In order to achieve the best effect of solar panels following the sun's rays, the existing solar automatic tracking systems usually set up two sets of completely independent control systems and structures for each solar panel to control the elevation angle of the solar panel, that is, the vertical direction The action and the movement from east to west, that is, the horizontal movement, so that each solar panel needs two sets of control systems to complete the solar panel perpendicular to the sun's rays, so that thousands of control systems are required in

solar power stations Tens of thousands of sets of control systems are used to complete the tracking of

solar energy for each solar panel. Although this control achieves the best tracking effect of solar panels on sunlight, the control structure is complex, which takes up a lot of space and is reliable. Poor performance, problems in the control process are not easy to maintain, the most important thing is to increase the cost of

solar power generation

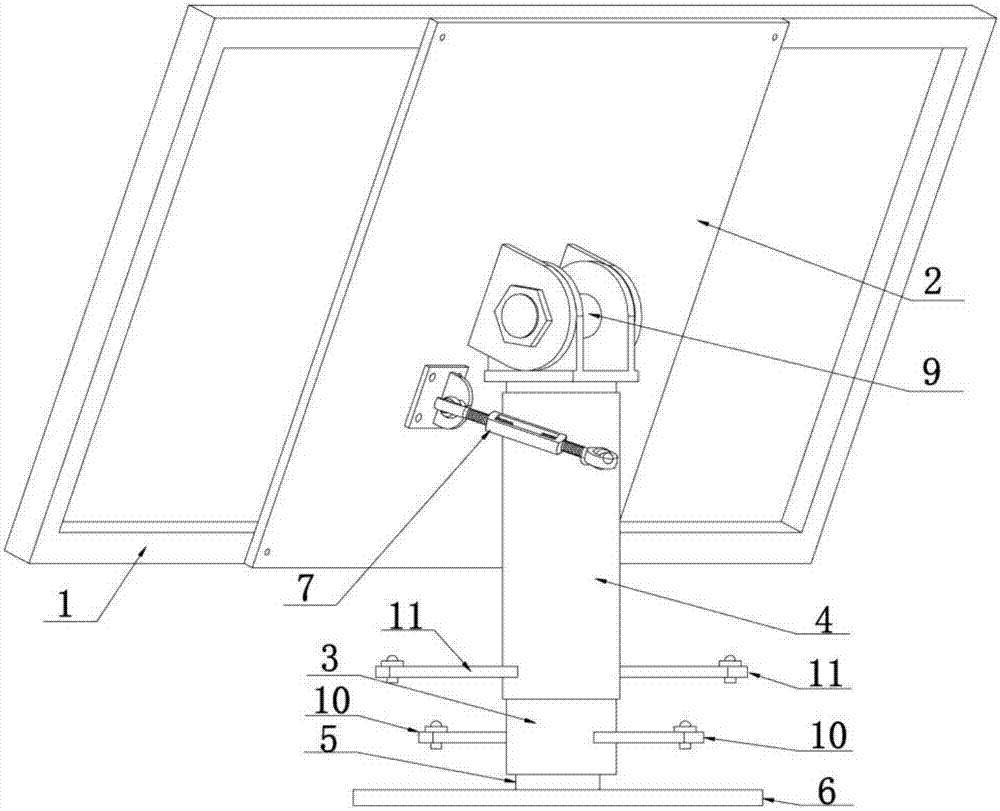

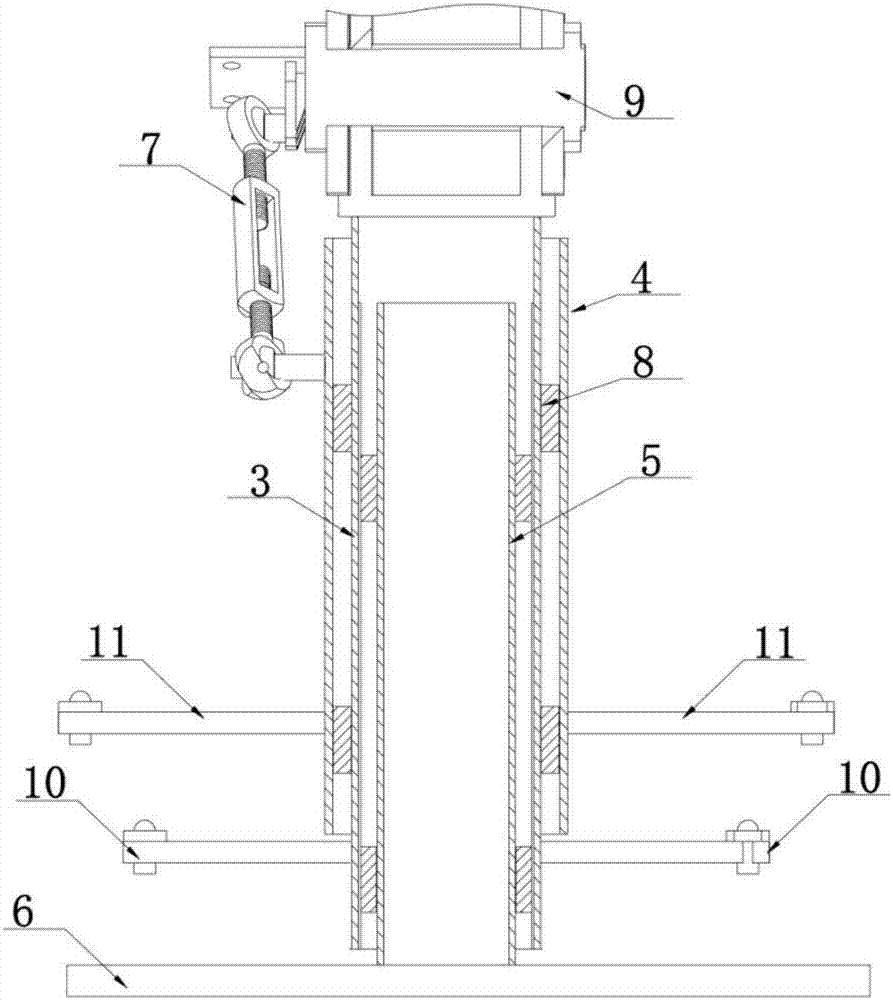

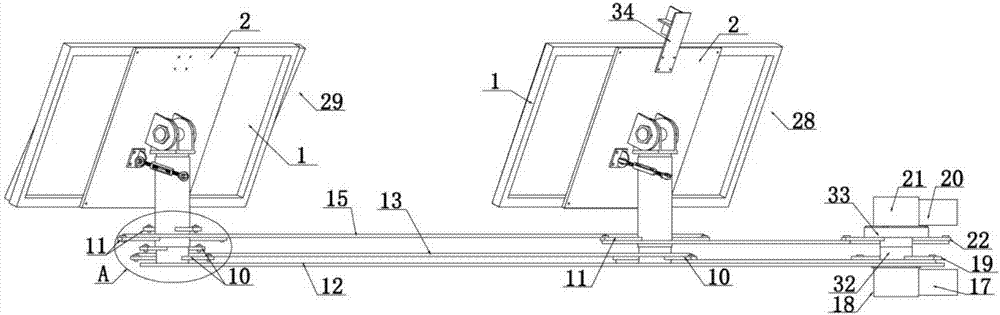

[0004] In order to simplify the

control system, a

solar tracking system with the existing publication number CN206193546U can control multiple solar panels through a set of control systems, but the tracking

system has the following defects: the horizontal adjustment

assembly of the panels can be adjusted horizontally The solar panel is adjusted. The adjustment of the elevation angle of the solar panel is not adjusted according to the light felt by the photoreceptor. After completion, the elevation angle of the solar panel is fixed. When the solar panel rotates on a fixed axis, the elevation angle of the solar panel will change. It is affected by the connection structure of the horizontal adjustment

assembly. The adjustment of the elevation angle in this patent is based on the change of the horizontal adjustment assembly, rather than adjusting the elevation angle of the solar panel according to the different angles of sunlight. In

actual use The change of the elevation angle in the process is greatly restricted, and it is impossible to accurately adjust the vertical direction of the solar panel. This patent only realizes the accurate adjustment of one degree of freedom of the solar panel in the horizontal direction. The effect of the solar panel tracking sunlight is poor, and it cannot Realize the purpose that the solar panel is always perpendicular to the sun's rays; the first and second photoreceptors receive the same

light intensity, and the solar panel does not need to be adjusted. When the first and second photoreceptors receive a deviation in the

light intensity, the photoreceptor The assembly transmits the

signal to the tracking controller, the tracking controller controls the

motor action, the motor drives the adjustment wheel to rotate, drives the tracking synchronous shaft to rotate, the first and second photoreceptors track the axis of the synchronous shaft to rotate, adjust the first and second The intensity of light received by the photoreceptor enables the solar panel to

follow the sun and move from east to west. The photoreceptor is only rotated and adjusted on the same horizontal plane, facing different heights of the sun's rays and irradiating both sides of the light shielding plate at the same time When it is on the first and second photoreceptors, no matter it is vertically irradiated or obliquely irradiated on the photoreceptors, as long as the first and second photoreceptors receive the same light, the tracking controller will not control the

motor action. From the above analysis, we can see The photoreceptor in this patent cannot distinguish the change in the height of the sun, that is, the photoreceptor in the above patent cannot adjust the elevation angle of the solar panel according to the height of the sun

In addition, the patent requires that multiple solar panels must be in the same row. If multiple rows of solar panels are designed, multiple sets of control systems are required. Each

control system controls multiple solar panels in the same row, although the control

system plays a certain role. However, the simplification effect is not good when faced with multiple rows of solar panels, and there are still problems of occupying a large space and high cost; therefore, there is an urgent need for a

solar tracking system with a simple structure and low cost, which can not only realize

solar energy The horizontal adjustment of the solar panel, and the elevation angle of the solar panel can be adjusted according to the sunlight to improve the effect of the solar panel tracking the sunlight

Login to View More

Login to View More  Login to View More

Login to View More