Uniformity restoration method after brightness correction of LED display screen

A technology of LED display and brightness correction, applied to static indicators, instruments, etc., can solve problems such as inaccurate calibration, dark on both sides, dark in the middle, bright on both sides, dark in the middle, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

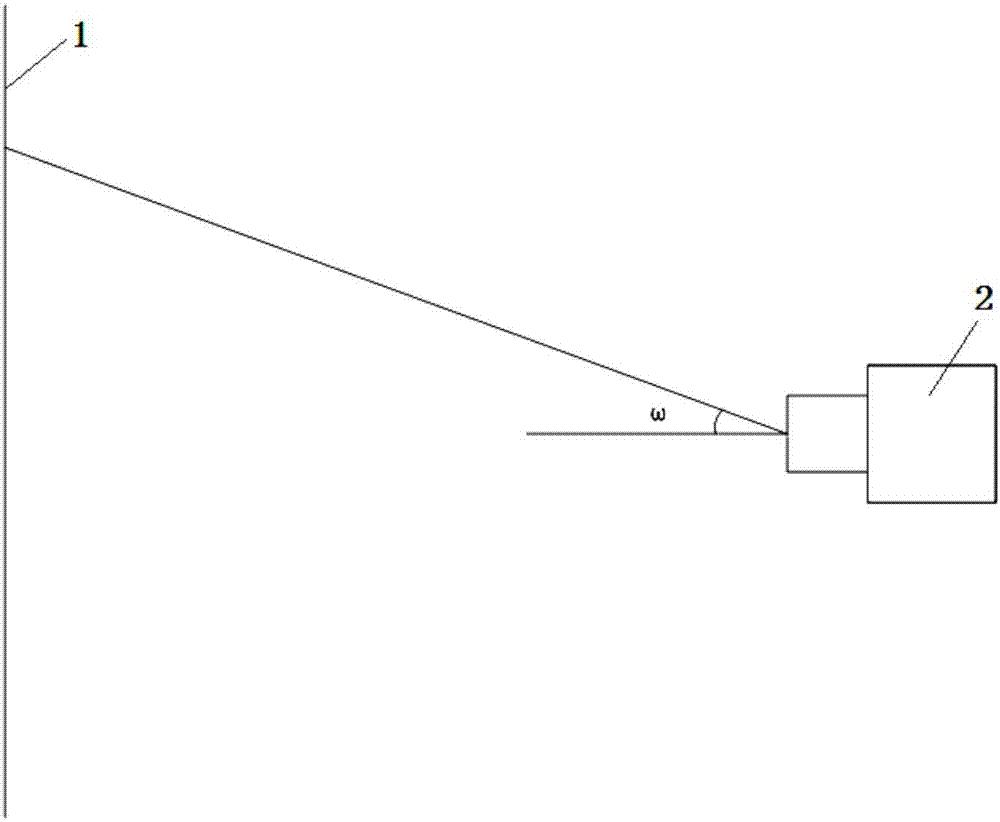

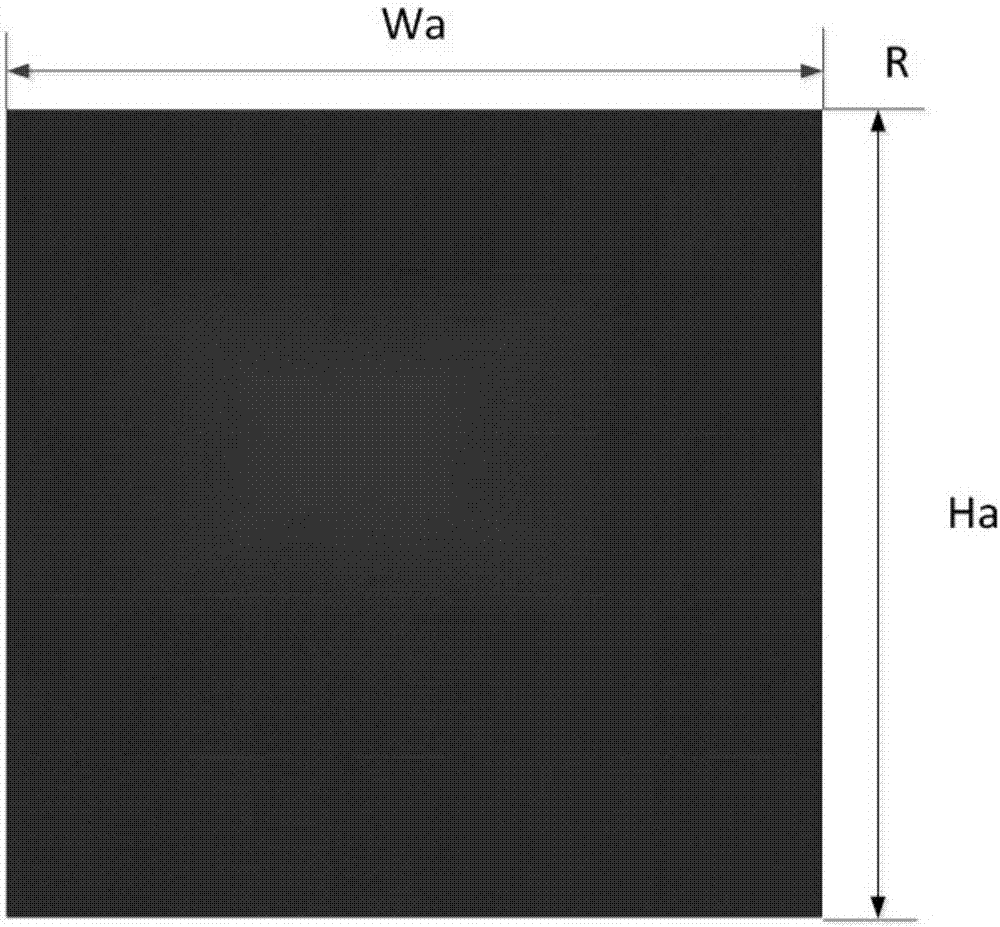

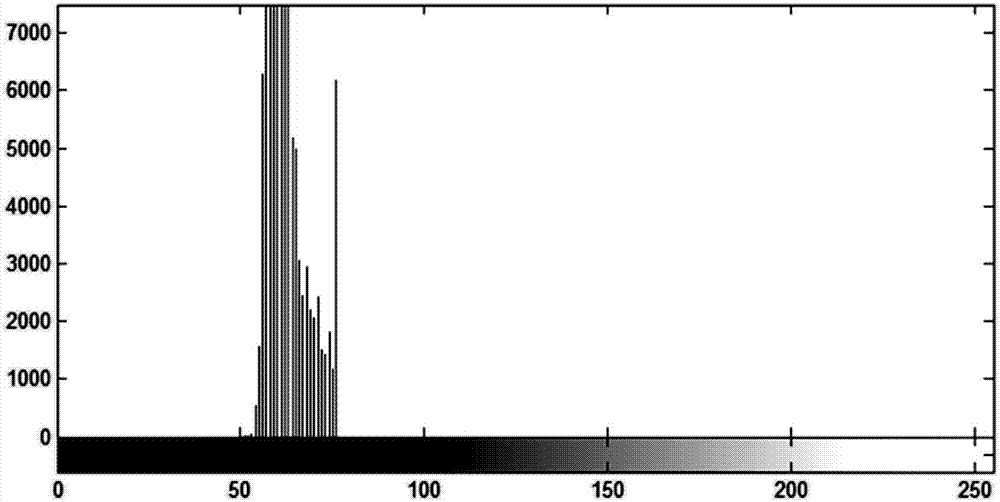

[0064] To calibrate the brightness of the LED display with the calibration equipment, it is first necessary to place the acquisition device 2 in front of the LED display 1 to collect the brightness parameters of the display, such as figure 1 As shown (ω in the figure is the incident angle of light collected by the LED at the off-axis point), the relative brightness values of red, green and blue colors of each LED light on the display screen are obtained, and then the respective correction coefficients are calculated according to the relative brightness values, and uploaded data and save it. Due to factors such as the inaccuracy of the acquisition equipment itself and optical imaging in the brightness correction acquisition system of the LED display, it will lead to the generation of the corrected curved surface.

[0065] The present invention realizes the uniformity restoration after the brightness correction of the LED display screen through the programming of the upper com...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com