Axial flow turbine

A technology of axial-flow turbines and fluids, applied in non-variable engines, mechanical equipment, engine components, etc., to achieve the effect of reducing short-circuit loss and leakage loss, and increasing rotation rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

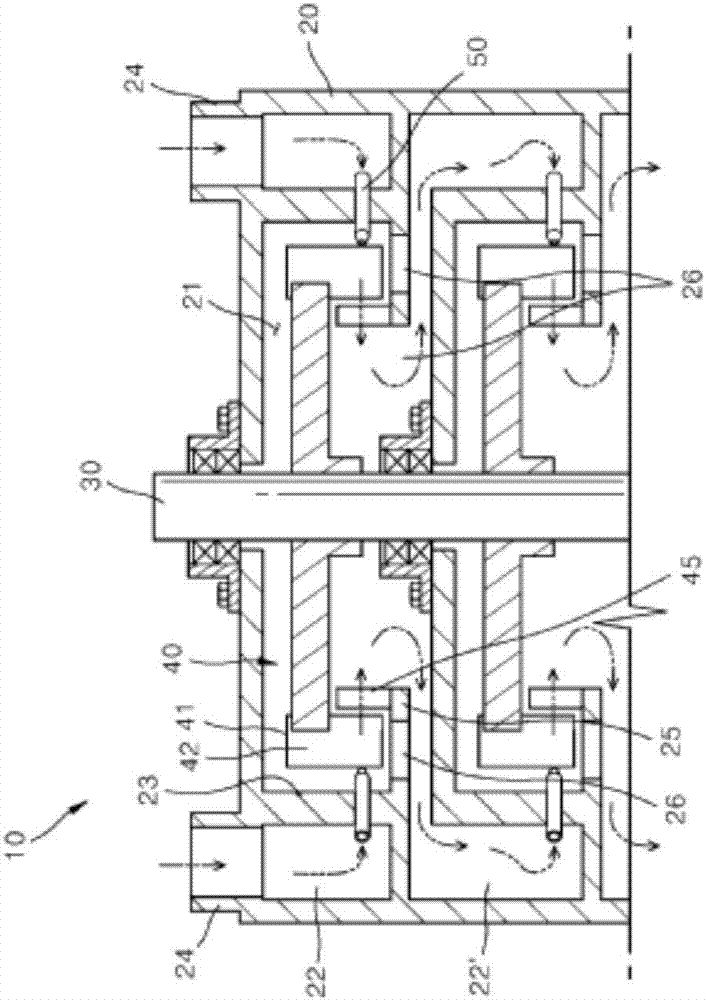

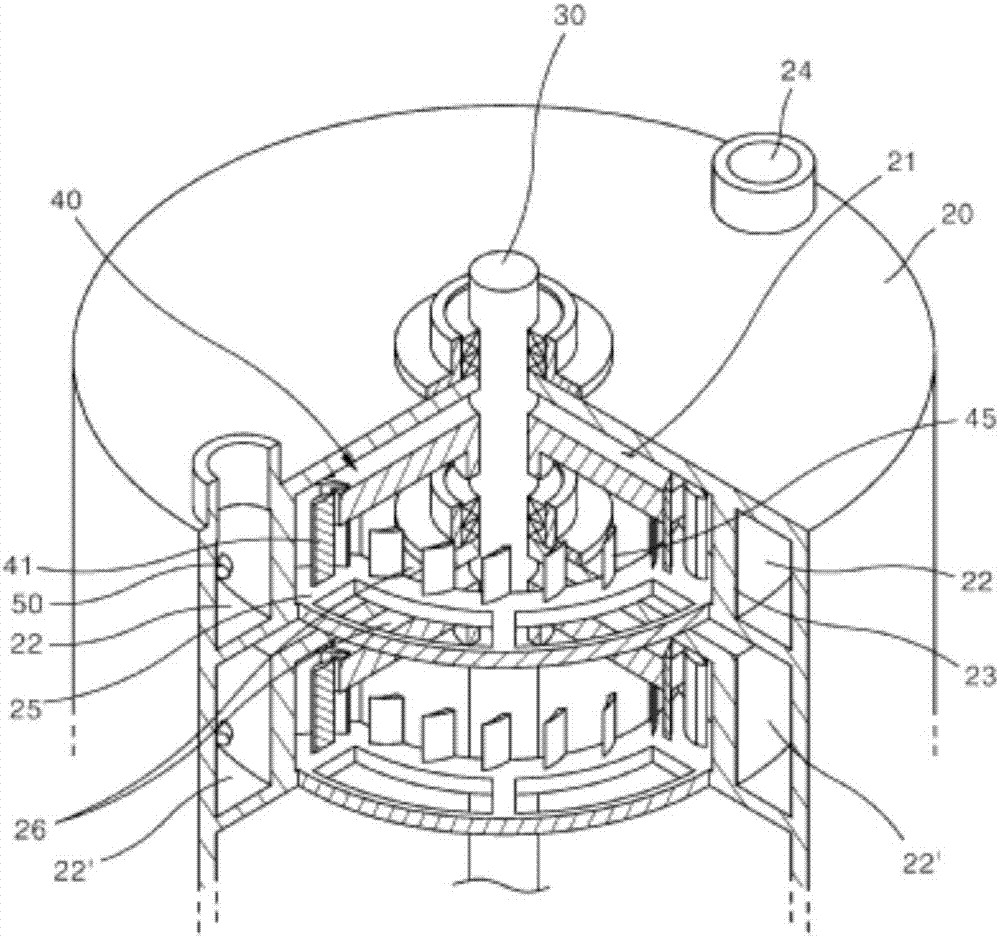

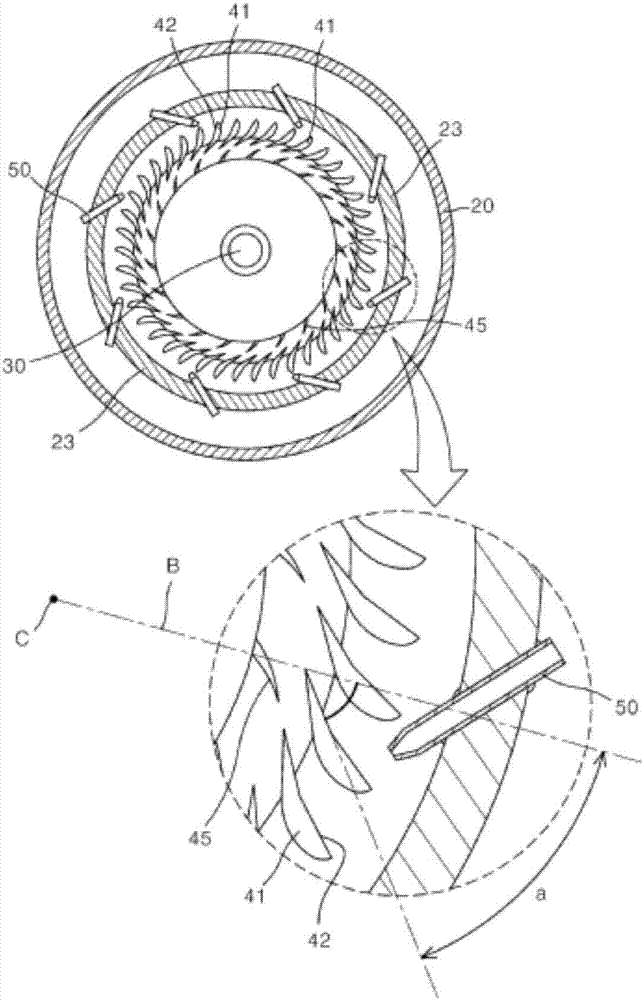

[0024] An embodiment of the axial turbine of the present invention is presented in Figure 1 to Figure 4 .

[0025] With reference to the drawings, the axial turbine 10 of the present invention includes: a housing 20 in which a rotor mounting portion 21 is formed, and the rotor mounting portion 21 and a fluid supply portion 22 partitioned by partition walls 23 are formed; the rotor 40 is provided in the above The rotating shaft 30 provided in the housing 20 is provided on the rotor mounting portion 21 to install a plurality of blades 41 along the circumferential direction; and a plurality of nozzles 50 are provided on the partition wall 23 and spray to the fluid collision surface 42 of the blade 41 The fluid supplied to the fluid supply unit 22 causes the rotor 40 to rotate.

[0026] A plurality of rotor mounting parts 21 of the housing 20 are stacked in the vertical direction of the rotating shaft 30 inside the housing 20, and a rotor 40 is provided in each rotor mounting part 21...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com