Spraying method capable of automatically generating spraying track and spraying device

A technology of automatic generation and spraying device, applied in the direction of spraying device, etc., can solve the problems of large workload, waste of paint, poor spraying quality, etc., to avoid waste, ensure spraying quality, and save labor costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

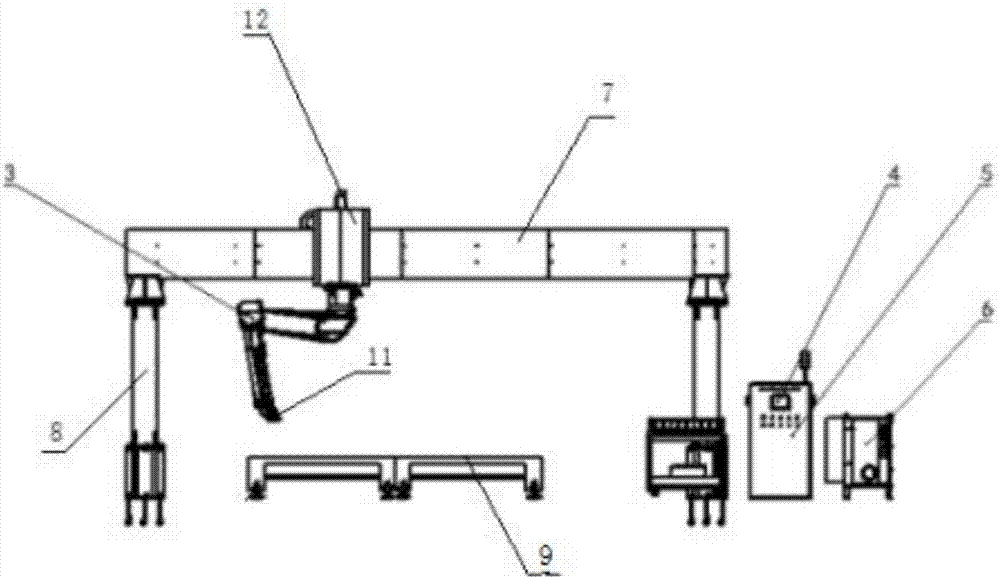

[0029] The present invention and the technical solutions in the embodiments of the present invention will be clearly and completely described below in conjunction with the accompanying drawings.

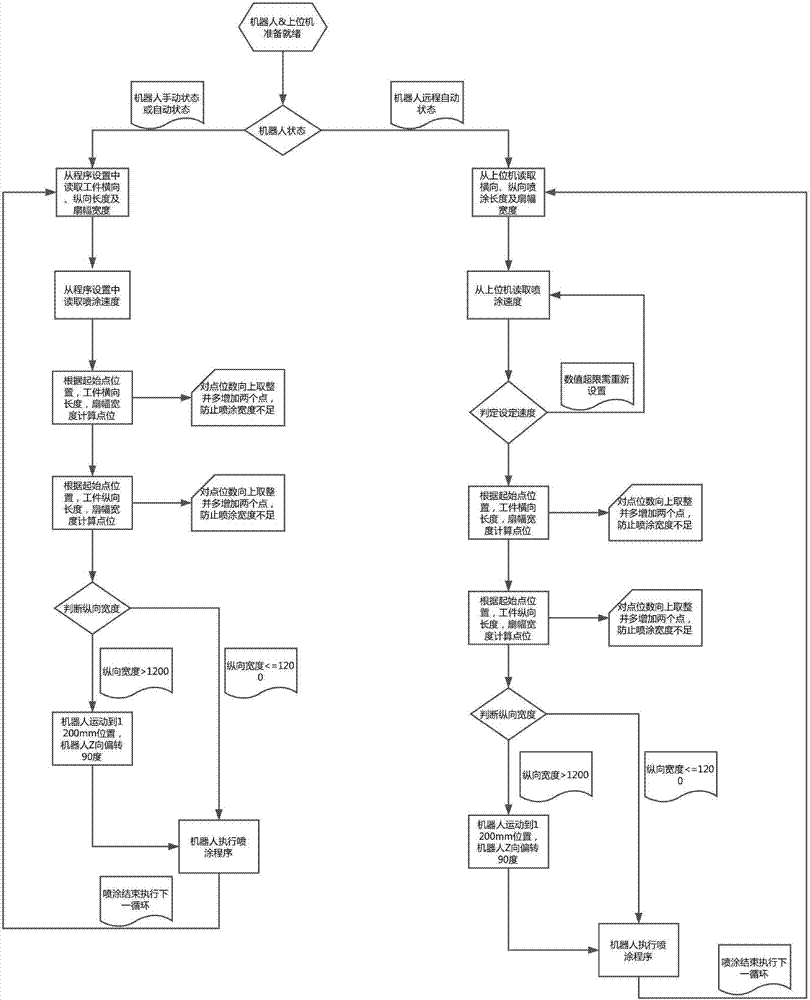

[0030] A spraying method capable of automatically generating spraying tracks, comprising the following steps;

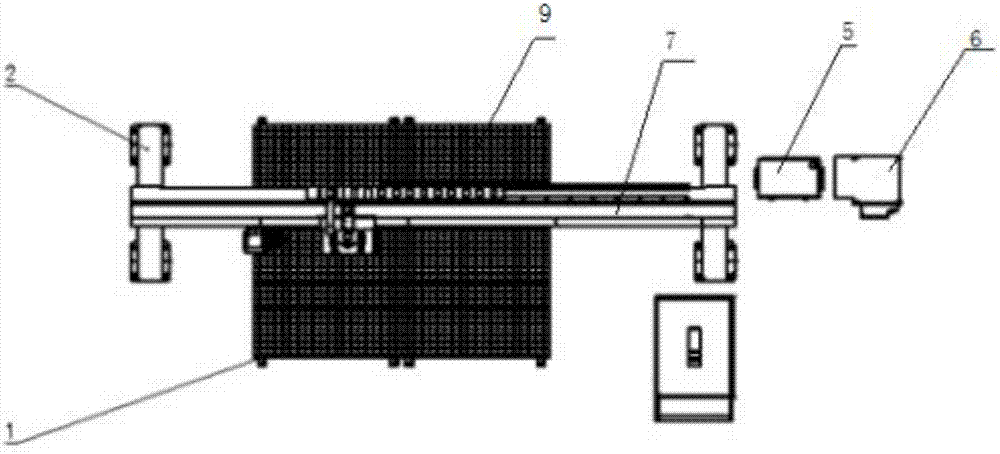

[0031] Step 1, place the workpiece to be sprayed on a tooling platform with a horizontal coordinate scale X axis and a vertical coordinate scale Y axis, and place the workpiece close to the coordinate origin and coordinate axis when placing;

[0032] Step 2, read the maximum value of the workpiece on the X axis and the maximum value on the Y axis, the main control cabinet 5 calls the system program of the robot 3, and enters these two values into the system program parameter input table, and sets the spraying speed Speed and fan width, that is, to generate the spray trajectory program;

[0033] Step 3, the starting point of the spray gun 11 controlled by the robot 3 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com