Rotary core-pulling device for outer deep undercut of fixed mold side of injection mold

An injection mold and core-pulling technology, which is applied in the field of deep-reverse rotary core-pulling devices on the fixed mold side of the injection mold, can solve the problems of large internal space, many links, and complex structure in the mold.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

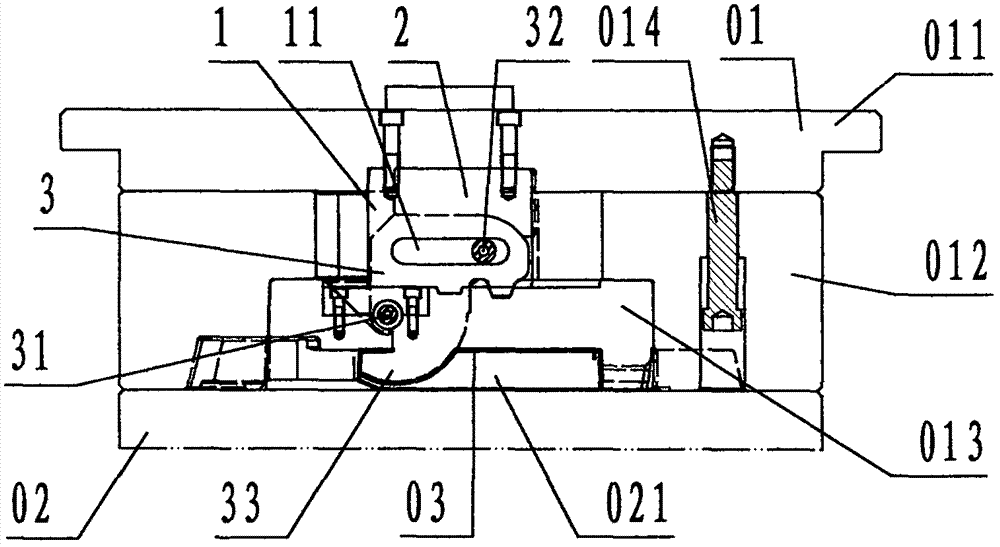

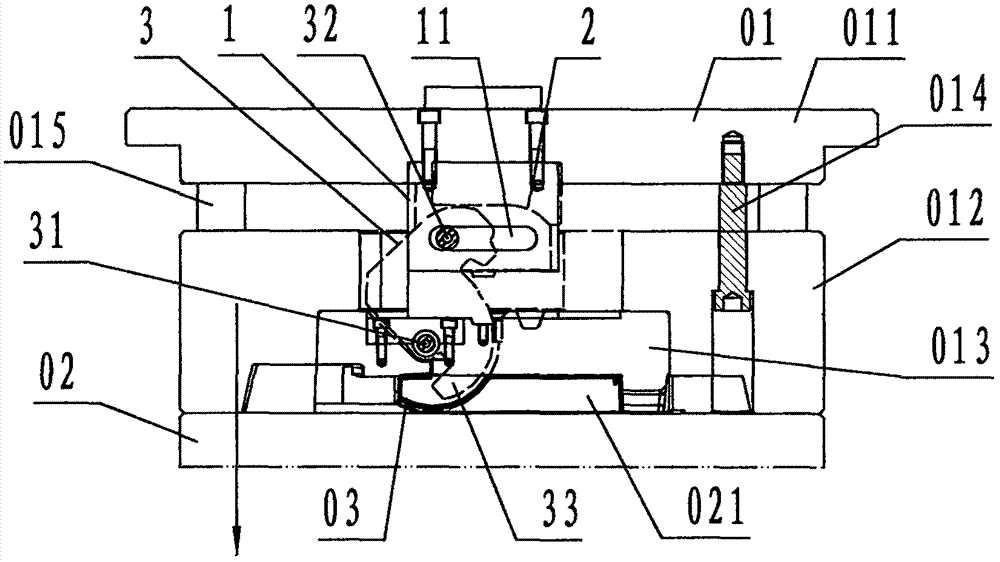

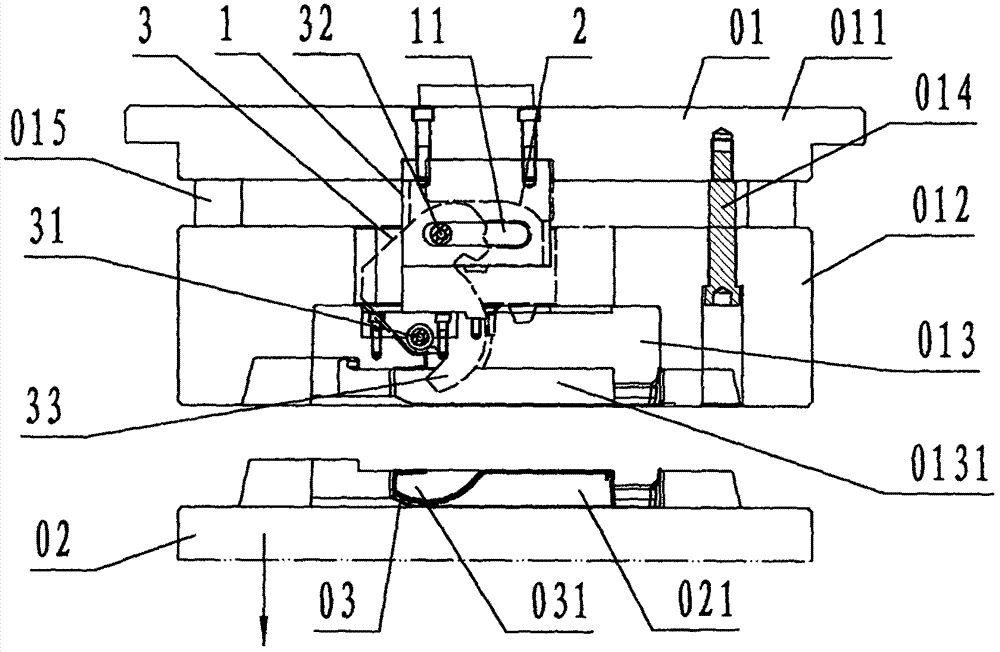

[0023] refer to Figure 1 to Figure 4 , a deep undercut rotary core-pulling device on the fixed mold side of the injection mold of the present invention, comprising a pull plate 1, a pressing block 2 and a deep buckle core block 3, wherein: the pull plate 1 is a rectangular plate-shaped steel Components, the lower part of the pull plate 1 is provided with a through hole in the shape of a horizontal oblong and the direction is the front and rear direction, which is called the guide hole 11;

[0024] The briquetting block 2 is an elongated block-shaped steel member that is rectangular in plan view and whose long side is in the front-rear direction. The bottom of the briquetting block 2 is provided with a shape corresponding to the top of the deep buckle core block 3;

[0025] The deep buckle core block 3 is a J-shaped hook-shaped main view, and a long block-shaped steel member whose long side is the front and rear direction when viewed from above. Cylindrical guide pin 32, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com