Safe three-dimensional garage

A three-dimensional garage and safety technology, applied in the field of garages, can solve problems such as uneven driving skills, potential safety hazards, unbalanced force on chains, etc., and achieve the effects of reducing safety hazards, reducing weight, and reducing pulling force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

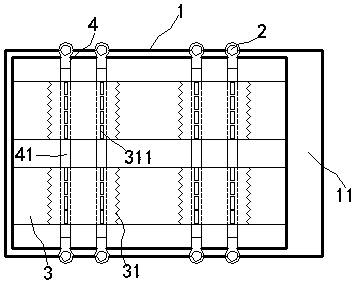

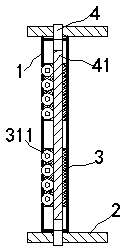

[0016] exist figure 1 , figure 2 In the shown embodiment, the safe three-dimensional garage includes a frame 1 and a lifting column 2, and the lifting column 2 is driven to rotate by a drive motor; the lifting column 2 passes through the side of the frame 1; have a wedge-shaped inlet 11;

[0017] On the frame 1 are fixedly provided with two bearing plates 3 vertically arranged in the horizontal direction, and two ends of each bearing plate 3 are provided with adjustment areas 31, and adjustment wheels are equidistantly arranged on the adjustment areas 31 311, the adjustment wheel 311 can freely rotate around its own axis; the axle of the adjustment wheel 311 is parallel to the bearing plate 3; the outer wheel surface of the adjustment wheel 311 is wrapped with a rubber layer;

[0018] Four transverse bearing rods 4 are also installed on the frame 1, the two ends of the bearing rods 4 are sleeved on the lifting column 2, and the bearing rods 4 and the lifting column 2 are ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com