Automatic travelling pipeline repair device and pipeline repair method

A pipeline repair and automatic walking technology, applied in the direction of pipes/pipe joints/fittings, pipe components, special pipes, etc., can solve the problems of green space and garden damage, underground pipes are not ventilated, and cannot enter the pipes, etc., to achieve convenient construction and improve Labor efficiency, the effect of ensuring safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

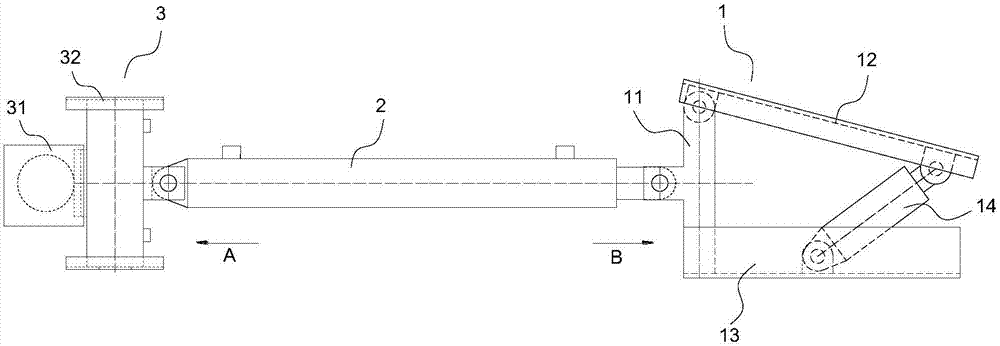

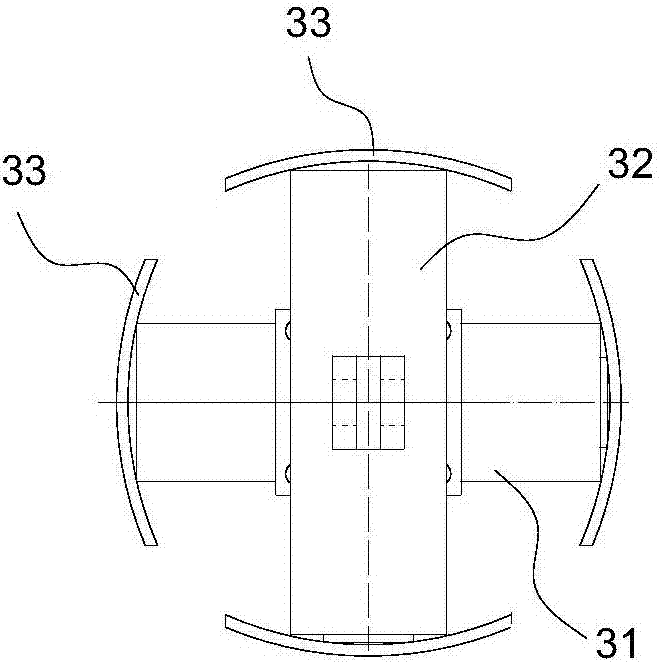

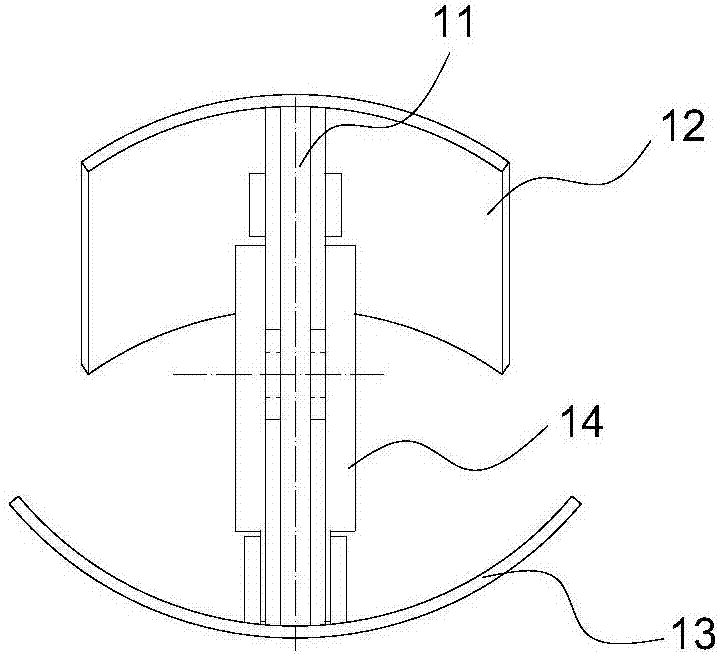

[0033] Such as Figure 1-4 As shown, an automatic walking pipeline repair device includes a repair device 1 for repairing a pipeline with a sunken inner wall, a travel cylinder 2 for driving the repair device, and a support cylinder for keeping the travel cylinder parallel to the inside of the pipeline to be repaired 3.

[0034] Specifically, the support cylinder 3 includes a first support cylinder 31 and a second support cylinder 32 arranged staggeredly on one side of the first support cylinder; the travel cylinder is horizontally arranged in the pipeline A to be repaired, that is, the travel cylinder and the central axis of the pipeline to be repaired Overlapping, one end of the travel cylinder is connected to the second support cylinder, and the other end is connected to the repair device. The walking oil cylinder can be a walking oil cylinder with a telescopic rod at one end in the prior art, or a walking oil cylinder with a telescopic rod at both ends. In addition, this...

Embodiment 2

[0041] A pipeline repair method, using the above automatic walking pipeline repair device for pipeline repair, specifically includes the following steps:

[0042] (1) Place the self-propelled pipeline repair device inside the sunken pipeline, and at the same time make the reset end fit the inner wall of the sunken pipeline;

[0043] (2) Start the first support oil cylinder and start the second support oil cylinder, so that the telescopic rods at both ends of the first and second support oil cylinders are extended outward until the entire automatic walking pipeline repair device is fastened in the pipeline to be repaired;

[0044] (3) Start the repair oil cylinder, the telescopic rod of the repair oil cylinder is extended, and drives the top reset plate to lift the sunken pipeline to the restoration state;

[0045] (4) Start the reset oil cylinder, and the telescopic rod of the repair oil cylinder shrinks back to the original state, driving the top reset plate to fall back;

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com