Railway shed tunnel T-shaped beam hoisting construction method

A construction method and shed hole technology, which are applied in hoisting devices, transportation and packaging, and load hanging components, etc., can solve the problems of on-site prefabrication and hoisting of T-beams on site, and high design requirements.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

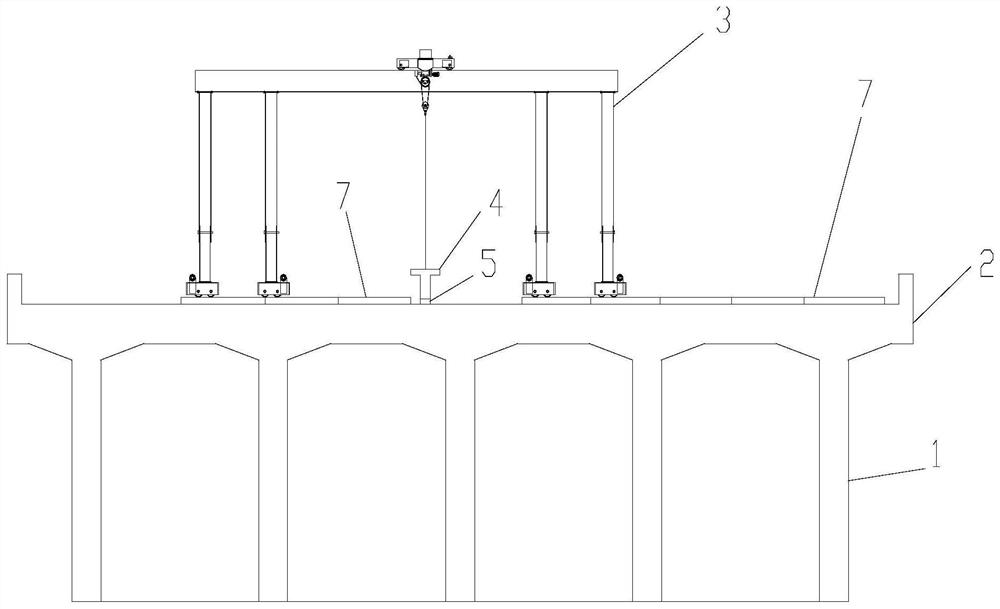

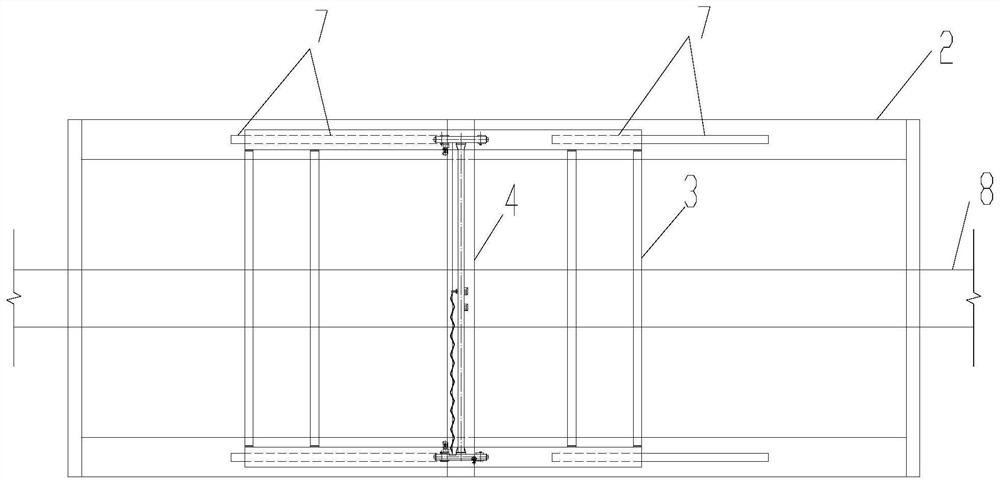

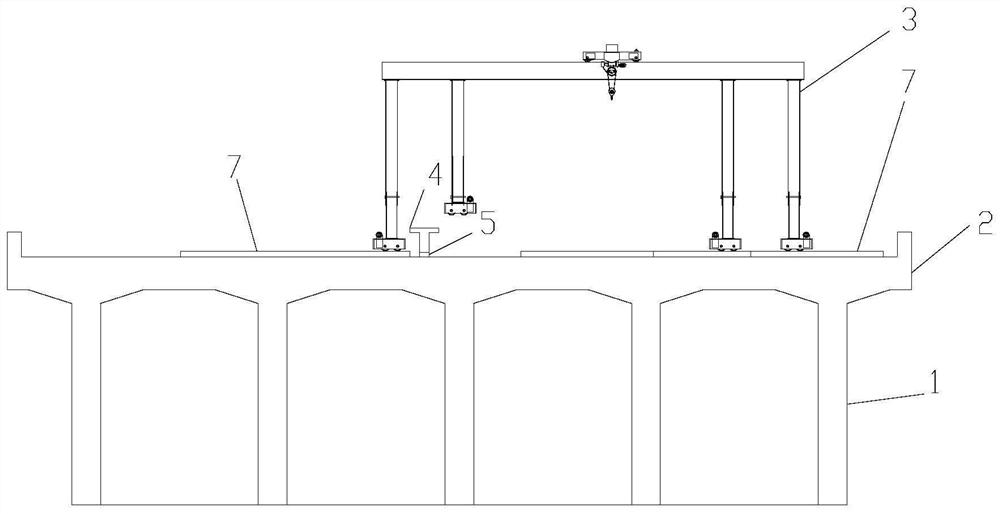

[0043] The construction method for hoisting the T-beam of the railway shed tunnel in this embodiment, wherein the T-beam 4 is prefabricated off-site, and the column 1 and the longitudinal beam 2 are installed in the foundation pit of the excavated shed cave, and the following steps are performed :

[0044] S1, such as figure 1 As shown, the ground under the longitudinal beam 2 is the existing railway track 8 leading to the off-site off-site (prefabricated T-shaped beam), hoists 6 are respectively installed on the ground at both ends of the longitudinal beam 2, and a simple gantry crane 3 is erected on the longitudinal beam 2 and crane tracks.

[0045] The simple gantry crane 3 is a telescopic multi-leg gantry crane with 4 groups of 8 outriggers along the traveling direction, with four front legs and four rear legs. The four front legs are divided into two parallel and opposite pairs along the running direction of the longitudinal beam 2, which are respectively a pair of fron...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com