Belt scale weight calibration method equivalent to material calibration

A calibration method and belt scale technology, applied in the field of belt scales, can solve the problems of many external constraints, untimely calibration, and high calibration cost, so as to achieve complete control of the calibration cost, stable calibration conditions, and high calibration costs. low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will now be described in further detail.

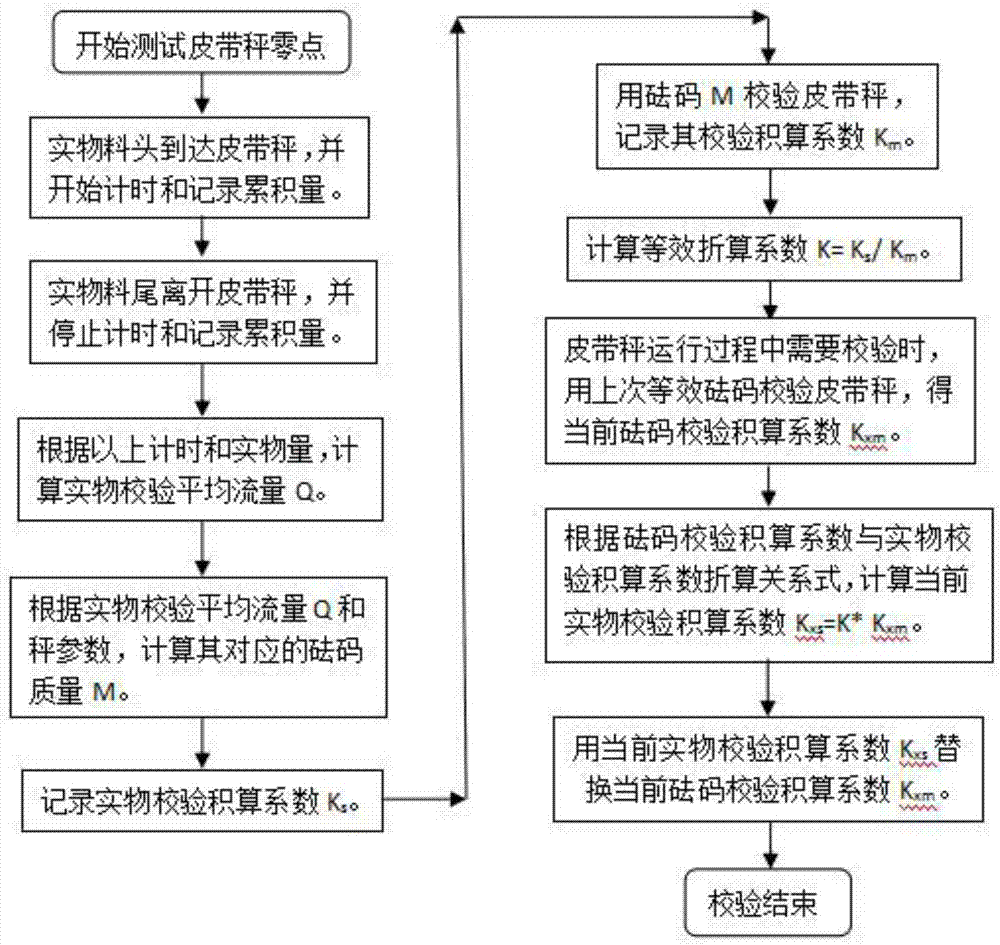

[0015] Such as figure 1 A method for verifying the weight of a belt scale equivalent to physical verification is shown, comprising the following steps:

[0016] Step 1: Under the condition that the parameters of the belt conveyor and its belt scale are the same as the external operating conditions (normal average load), respectively test the integration coefficients Ks and Km of the belt scale in the two verification methods of the physical object and the weight, where Ks is the actual object Calibration integral coefficient, Km is the calibration integral coefficient of weight M;

[0017] Step 2: Calculate the proportional coefficient K=Ks / Km between the two according to Ks and Km;

[0018] Step 3: When the belt scale needs to be calibrated during operation, use the last equivalent weight to calibrate the belt scale to obtain the current weight calibration cumulative coefficient Kxm; according to the cu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com