Sensor fixing device of acoustic emission test

A technology for fixing devices and sensors, which is applied in the direction of measuring devices, material analysis using acoustic emission technology, instruments, etc., can solve the problem of affecting the normal progress of uniaxial compression acoustic emission tests, inaccurate spatial position fixation of sensors, increasing specimen loss and Time-consuming test and other problems, to achieve the effect of simple structure, accuracy assurance, and easy replacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] An embodiment of the present invention will be further described below in conjunction with accompanying drawing:

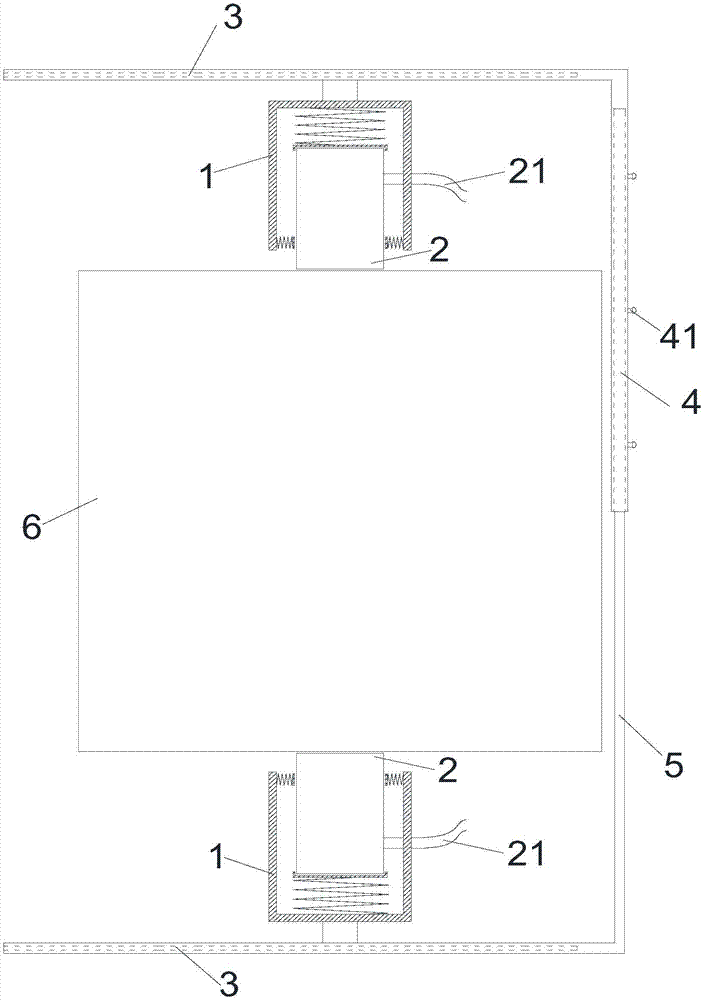

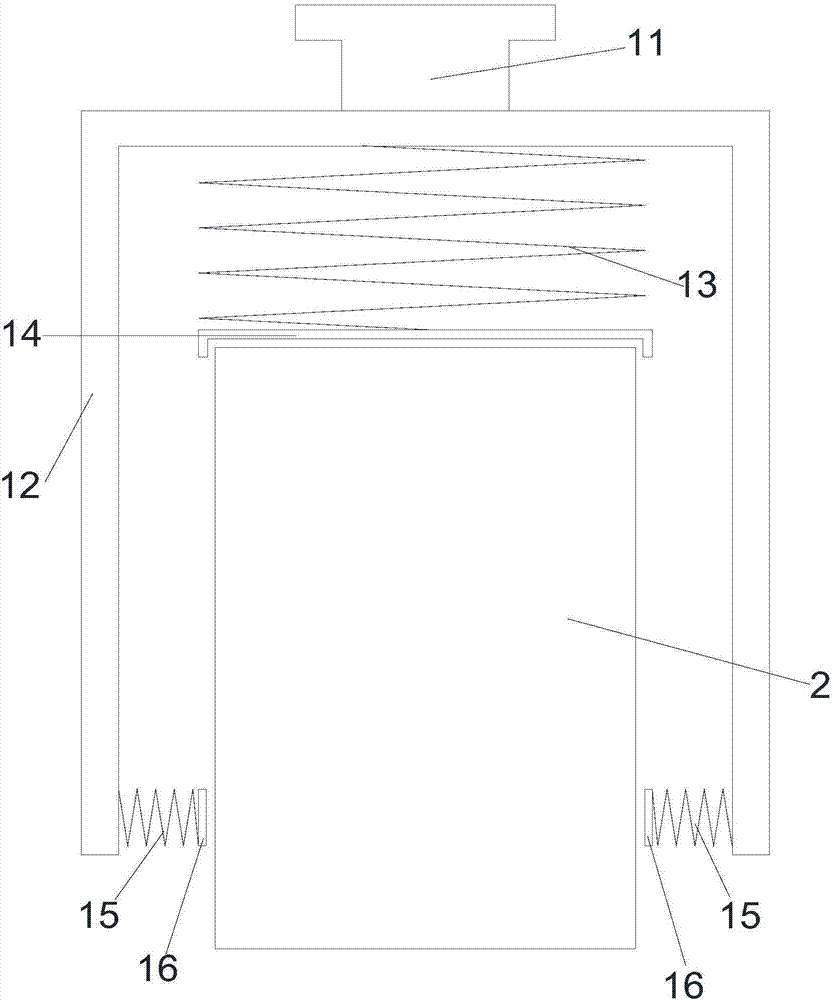

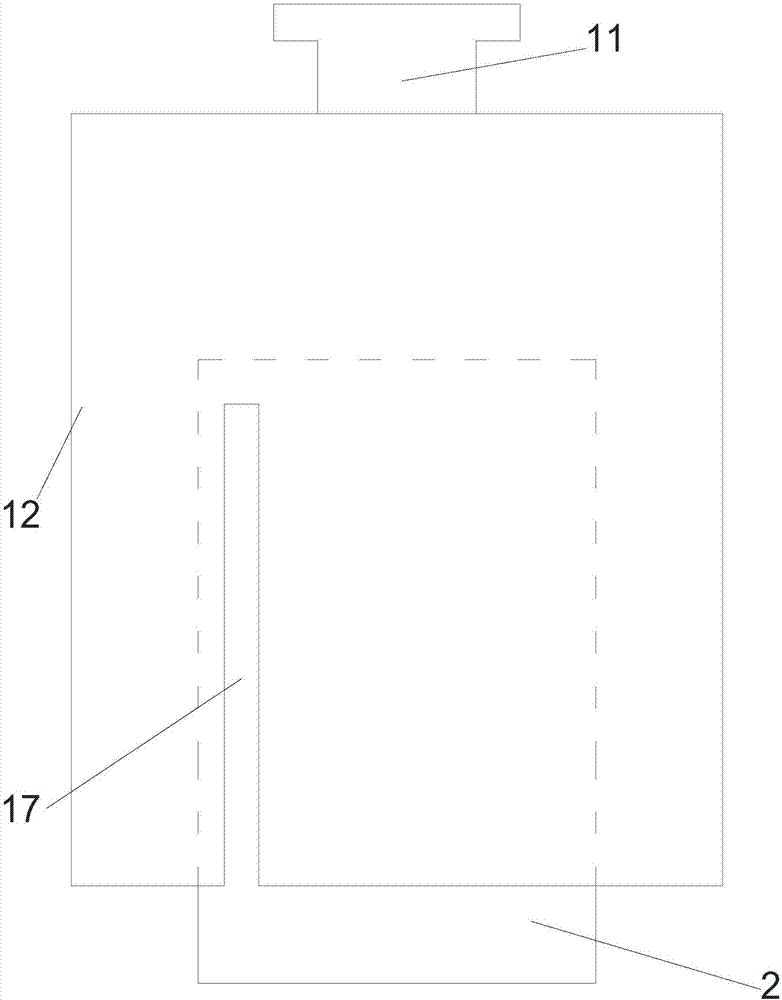

[0024] Such as figure 1 As shown, a sensor fixing device for acoustic emission test of the present invention includes a fixing mechanism 1 of the sensor body, a socket bracket 3 , a socket rigid bracket 4 , and a solid rigid bracket 5 . Such as figure 1 , figure 2 , image 3 As shown, the fixing mechanism 1 of the sensor body is used to adjust and fix the sensor, and the mechanism is arranged inside the hollow cylindrical shell 12; the fixing mechanism of the sensor body is inserted into a slot bracket provided with a half-shaped slot 31 through a plugboard 11 3; the sensor body 2 is put into the mechanism by the sensor cover 14, the limit spring 15, and the limit plate 16 is fixed to it, and the sensor wire is protruded from the bar-shaped gap 17; The sensor body is closely combined with the test piece 6. Such as figure 1 , Image 6 As shown, two s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com