MEMS magnetic field sensor of folded beam structure and preparation method

A magnetic field sensor and beam structure technology, applied in the direction of the size/direction of the magnetic field, instruments, measuring magnetic variables, etc., can solve the problems of low sensitivity, complex manufacturing process, poor stability, etc., and achieve the effect of high applicability and high sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

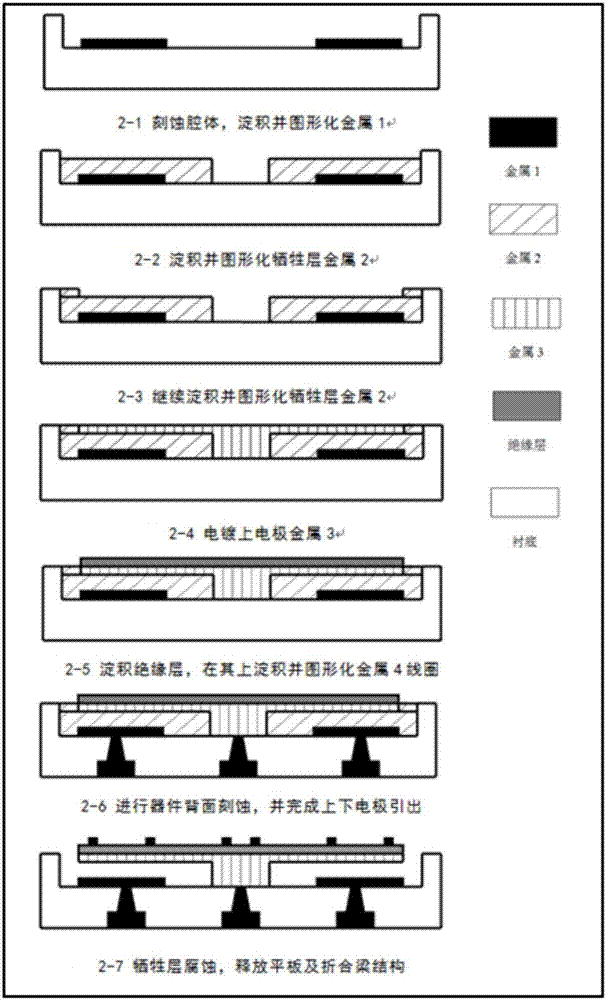

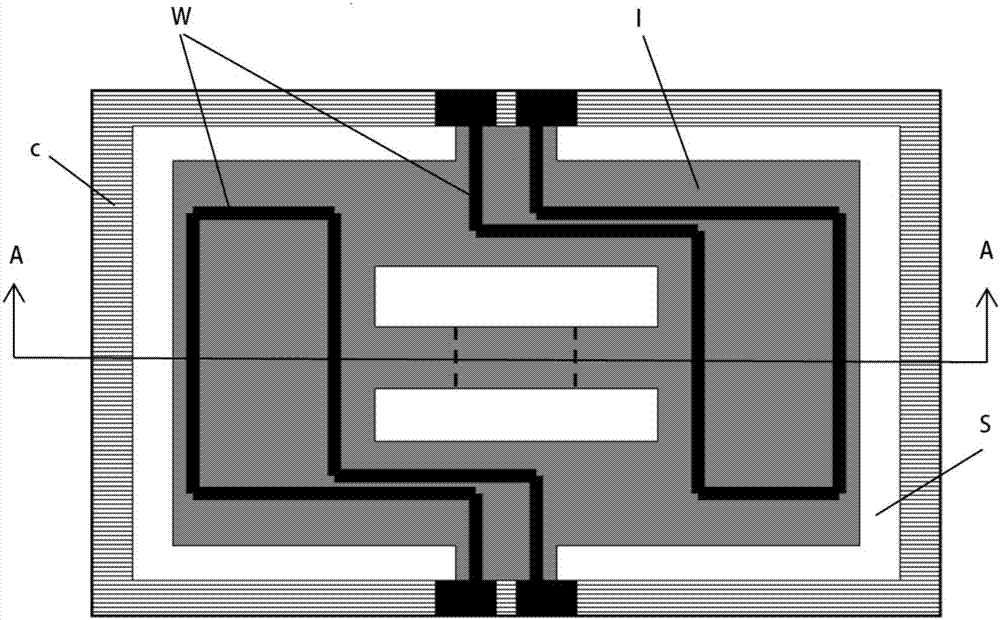

[0049] The structural features and technical details of the present invention will now be described in detail in conjunction with the accompanying drawings.

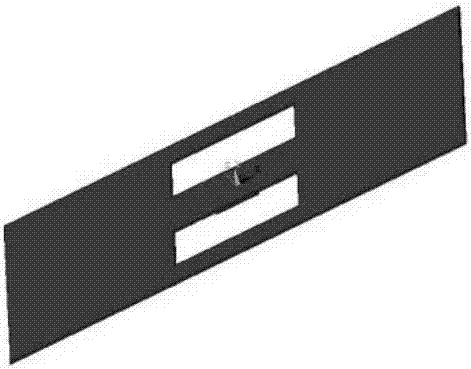

[0050] see figure 1 , 3 And 4, a kind of MEMS magnetic field sensor of folded beam structure, is made up of folded beam structure and substrate; The electrodes of the beam structure and the electrodes on the substrate form a variable capacitance; an insulating layer is provided on the upper surface of the folded beam structure, and a metal coil is provided on the insulating layer; after the current is passed through the metal coil, it is subjected to Lorentz in the magnetic field. The force makes the folded beam structure bend and deform, thereby changing the electrode spacing between the folded beam structure and the substrate, and realizing the change of the capacitance value; the capacitance change trend at both ends of the folded beam structure is opposite, forming a differential capacitance; the magnetic field is o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com