Preparation method of mems magnetic field sensor using folded beam structure

一种磁场传感器、梁结构的技术,应用在磁场的大小/方向、仪器、测量磁变量等方向,能够解决制作工艺复杂、灵敏度低、稳定性差等问题,达到提高灵敏度、不易材料疲劳断裂、好机械性能稳定性的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

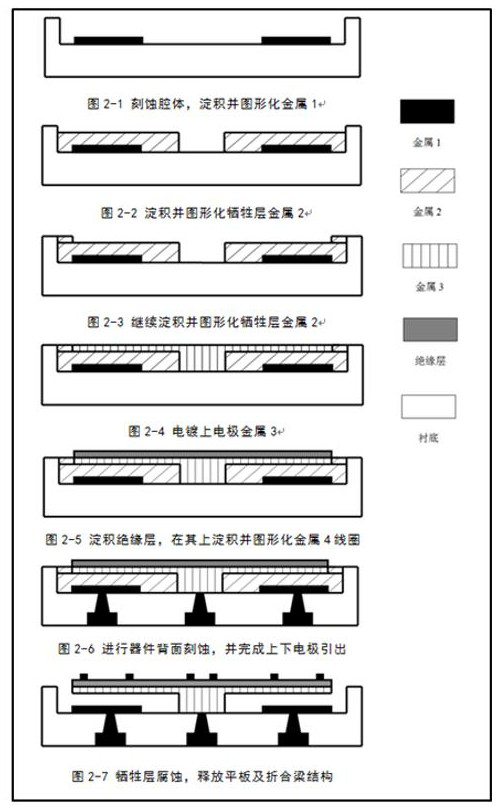

[0050] Presently combined with the accompanying drawings in detail the structural characteristics and technical details of the present invention.

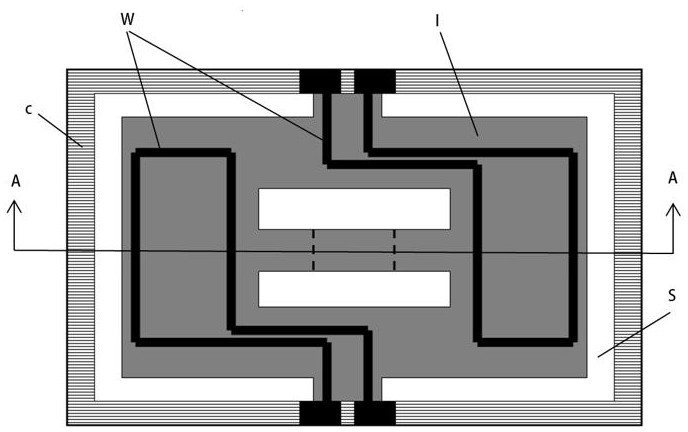

[0051] See Figure 1 、 3and 4, using a mems magnetic field sensor with a folded beam structure, consisting of a folded beam structure and a substrate; The material of the folded beam structure is metal and is T-shaped; The folded beam structure itself becomes an electrode, and there is an electrode on the substrate; The electrodes of the folded beam structure form a variable capacitance with the electrodes on the substrate; An insulating layer is provided on the upper surface of the folded beam structure, and a metal coil is provided on the insulation layer; After the metal coil is introduced into the current, it is subjected to the Lorentz force in the magnetic field to bend and deform the folded beam structure, thereby changing the electrode spacing between the folding beam structure and the substrate, and realizing the change of the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

| Sensitivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com