A Method for Determining the Load-end Contraction Curve of Longitudinal Multi-span Instability

A method for determining the longitudinal bone, applied in the direction of instrumentation, geometric CAD, design optimization/simulation, etc., can solve the problems of high requirements, large modeling and calculation time, etc., to achieve ship design safety, expand calculation accuracy, improve accuracy and speed effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0055] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

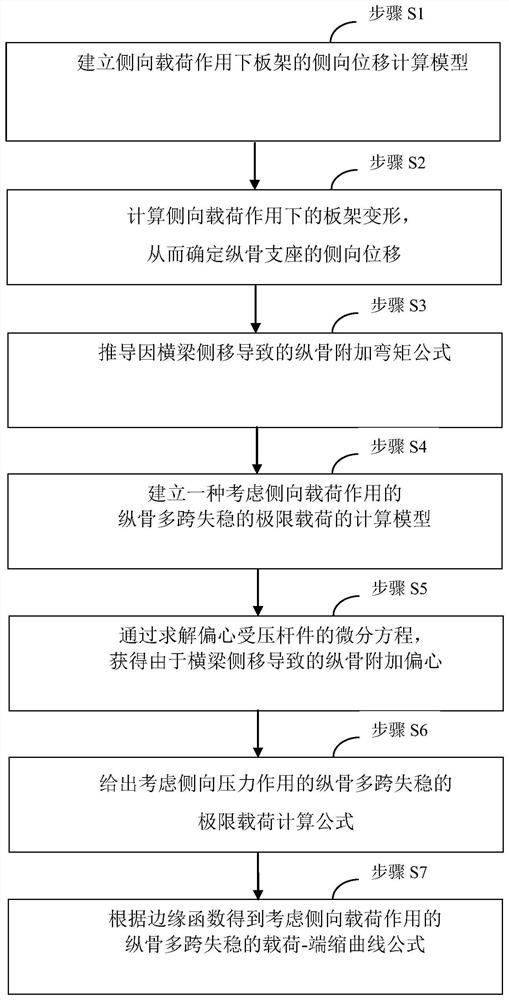

[0056] In a preferred embodiment, as figure 1 As shown, a method for determining the load-contraction curve of longitudinal multi-span instability considering the lateral load.

[0057] Methods of determination may include:

[0058] Step S1, establishing a calculation model for the lateral displacement of the plate frame under the action of the lateral load;

[0059] Step S2, using the beam as the elastic support of the longitudinal frame, according to the simple frame theory of "Ship Structural Mechanics", calculate the deformation of the frame under the action of lateral load, so as to determine the lateral displacement of the longitudinal frame support;

[0060] Step S2, deriving the formula for the additional bending moment of the longitudinal bone caused by the lateral movement of the beam;

[0061] Step S3, introduce the overall deformation of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com