A three-dimensional design method for the filling system of high-level water-receiving cooling tower

A high-level water collection and three-dimensional design technology, applied in the field of cooling towers, can solve the problems of inability to achieve linkage modification, high requirements for engineers, and heavy workload, and achieve the effect of reducing manual reading, simplifying design procedures, and inputting less data

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described below in conjunction with the accompanying drawings.

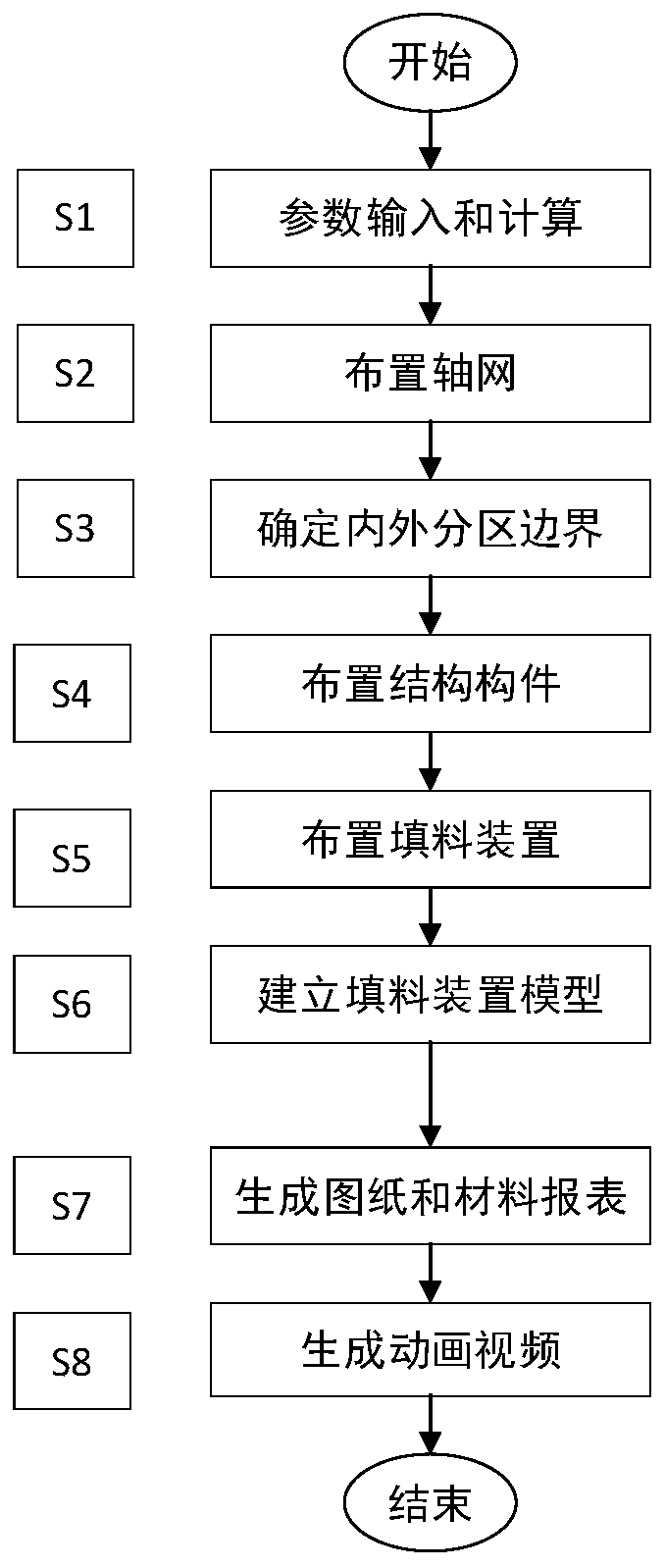

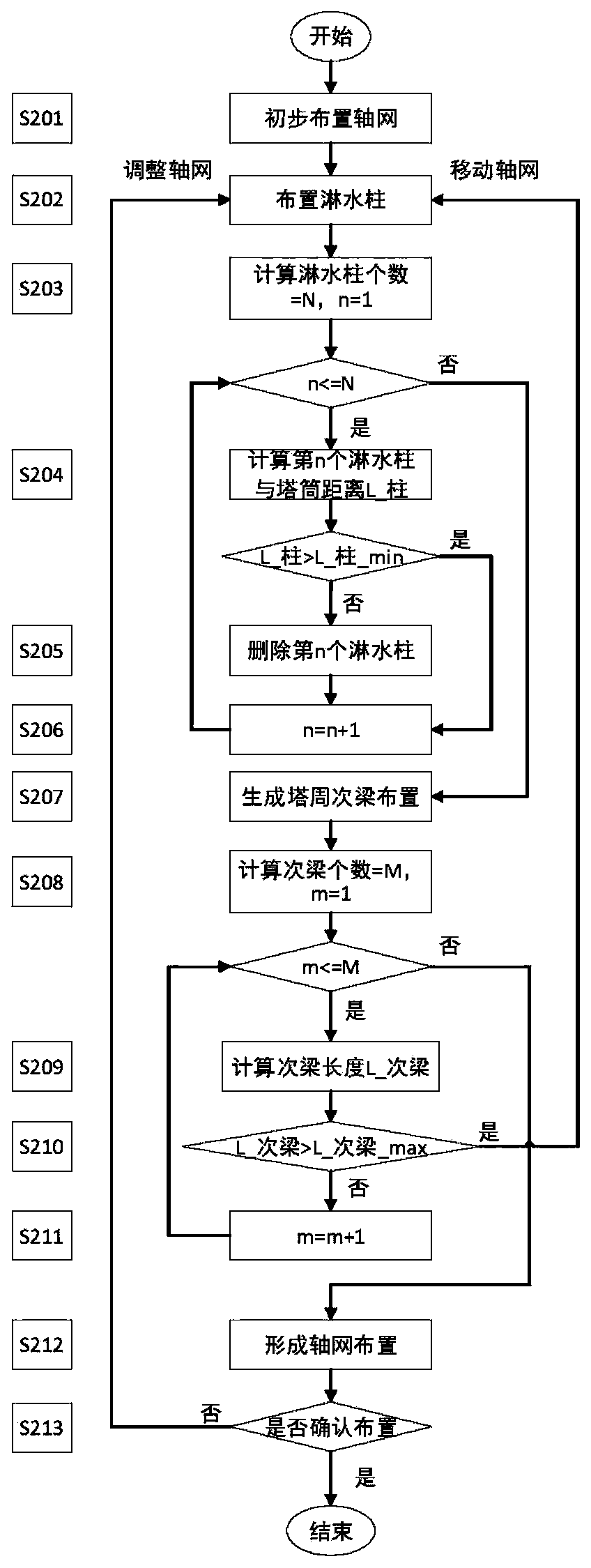

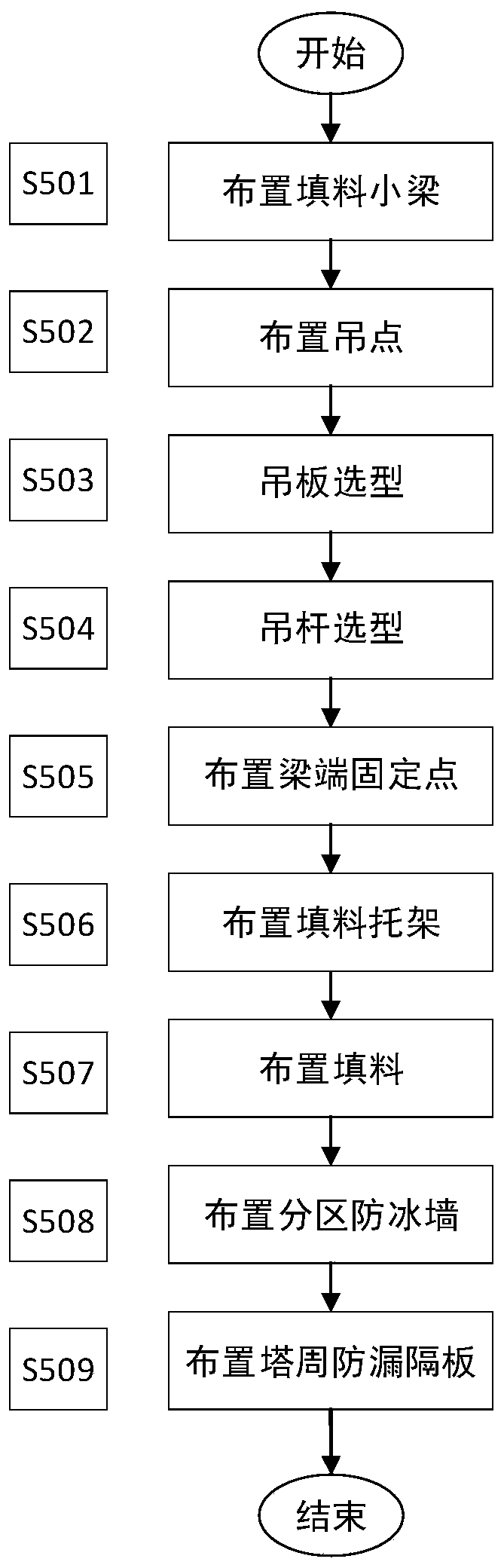

[0029] A three-dimensional design method for a filling system of a high-level water collection cooling tower, specifically comprising the following process: step S1, inputting design parameters of the filling system; step S2, selecting a quadrant to arrange a grid; step S3, determining the inner and outer partition boundaries on the grid; Step S4, arranging structural components on the grid to form a simplified model with component occupancy; Step S5, arranging the packing system on the basis of the simplified model; Step S6, establishing a packing system model according to the symmetric relationship of quadrants; Step S7, generating drawings and Material statistics report; step S8, generating video animation. In this embodiment, Revit can be used as the BIM three-dimensional design software, and C# can be used as the secondary development tool. Through this implementa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com