Special tool for dismounting intermediate joint of disconnecting switch

A technology of intermediate joints and special tools, which is applied in the direction of switchgear, electrical components, etc., can solve the problems of cumbersome operation steps, high operation risk, equipment damage, etc., and achieve the effect of fast and efficient removal, ensuring operation safety and fixed force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

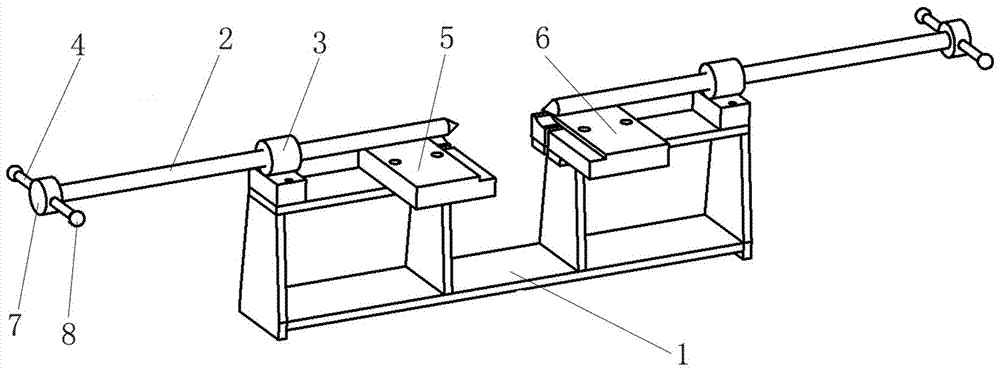

[0020] Such as figure 1 As shown in the figure, a special tool for dismantling the intermediate joint of a disconnector includes a base 1 and two screw rods 2. A screw positioning seat 3 is provided on both sides of the upper surface of the base 1, and the screw positioning seat 3 has internal threads. The two screw rods 2 are threadedly connected with a screw rod positioning seat 3 respectively and the two screw rods 2 are located on the same axis, and the opposite ends of the two screw rods 2 are provided with operating handles 4 .

[0021] The opposite ends of the two screw rods 2 are conical heads. The tapered head is more conducive to applying a thrust to the main shaft of the intermediate joint, and at the same time reduces the resistance when the screw rod 2 rotates.

[0022] The middle part of the upper surface of the base 1 is also provided with a positioning jig for fixing the intermediate joint. The positioning jig includes a left jig 5 and a right jig 6. The oppos...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com