Organic waste gas treatment system and method

A technology of organic waste gas and treatment method, applied in gas treatment, separation methods, chemical instruments and methods, etc., can solve the problem of high energy consumption, achieve the effect of improving treatment efficiency and avoiding easy saturation

Inactive Publication Date: 2017-10-24

ZHEJIANG UNIV

View PDF6 Cites 6 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

General processing 10000m 3 /h of exhaust gas requires about 90kW

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Login to view more

Login to view more PUM

Login to view more

Login to view more Abstract

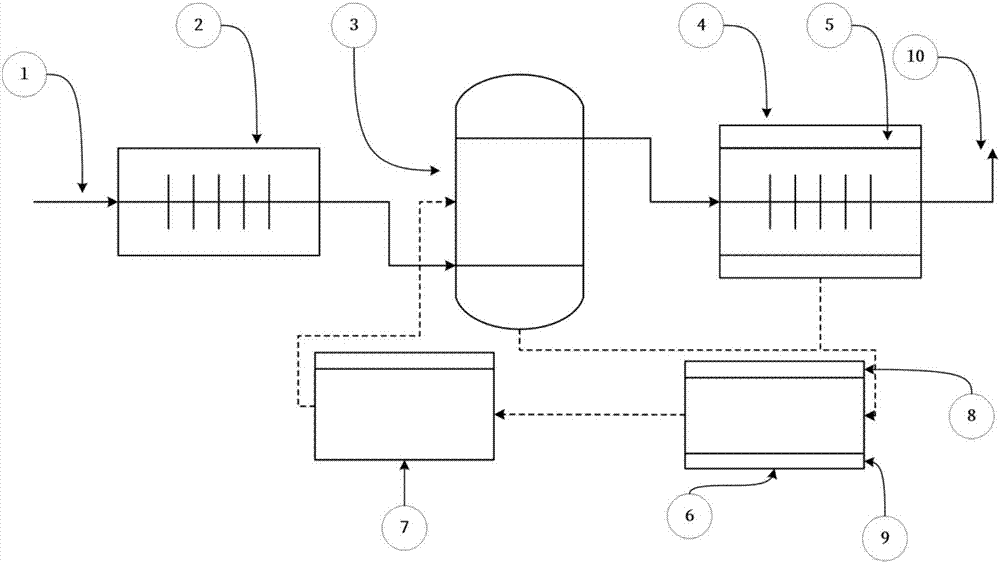

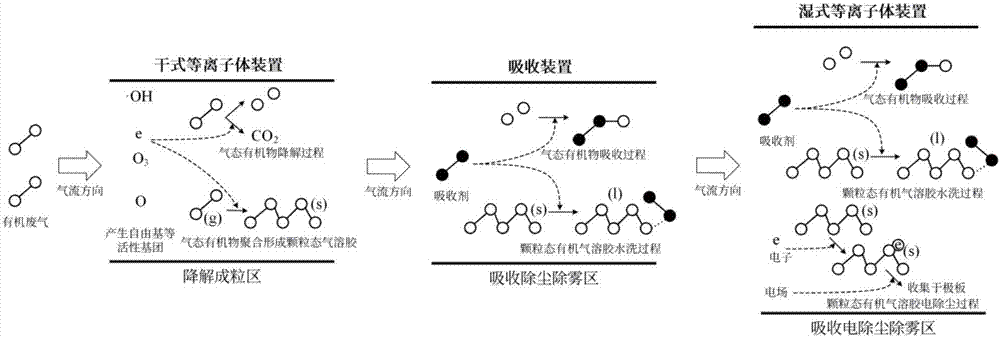

The invention discloses an organic waste gas treatment method, comprising: introducing organic waste gas into a dry plasma device to perform degrading and granulating so as to form a charged aerosol solid byproduct, as well as primarily-purified gas and charged aerosol solid byproduct; feeding the primarily-purified gas and charged aerosol solid byproduct into an absorbing device to primarily absorb and capture gas and aerosol solid byproduct so as to obtain further-purified gas and aerosol solid byproduct; feeding the further-purified gas and aerosol solid byproduct into a wet plasma device to further degrade and intensively absorb organic waste gas and capture aerosol solid byproduct so as to obtain purified gas. The invention also discloses an organic waste gas treatment system and application thereof. The method of the invention has the advantages that organic waste gas is treated via low-temperature plasma in combination with the absorbing device and a demisting device, organic waste gas collection conditions are lowered, collection efficiency is improved, and treatment cost is lowered.

Description

technical field [0001] The invention relates to the field of waste gas treatment, in particular to a treatment system and method for organic waste gas. Background technique [0002] Volatile organic gases (VOCs) refer to various organic compounds with a boiling point of 50-260°C under normal pressure. According to its chemical structure, it can be divided into: aromatic hydrocarbons, halogenated hydrocarbons, aldehydes, alcohols, mercaptans, amines, ketones, ethers, etc. The discharge of these VOCs into the air not only directly harms the human nervous and immune system, but also easily produces secondary pollutants such as aerosols, causing more serious environmental problems. The total amount of VOCs emissions in my country is very large, and the VOCs pollution in typical industries is very serious, and there is a continuous growth trend. The control of VOCs emissions is very urgent. [0003] For traditional technologies, such as combustion and condensation, the removal ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to view more Application Information

Patent Timeline

Login to view more

Login to view more IPC IPC(8): B01D53/74B01D53/72

CPCB01D53/74B01D53/72B01D2257/708B01D2259/818

Inventor 李树然邓官垒黄逸凡郑钦臻闫克平

Owner ZHEJIANG UNIV

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap