Adjustable spray coating hoisting mechanism

An adjustable and hoisting technology, applied in the direction of the spraying device, can solve the problems of large paint distribution area, long hoisting distance, waste, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

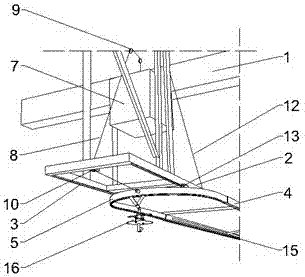

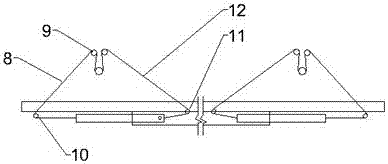

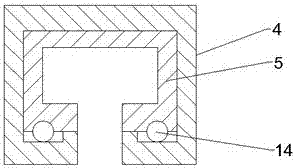

[0014] Below in conjunction with all accompanying drawings the present invention will be further described, and preferred embodiment of the present invention is: see appended figure 1 to attach image 3 , the adjustable spraying hoisting mechanism described in this embodiment includes several hoisting brackets 1 arranged in turn and fixed in the spraying workshop. The two ends of the position track 2 are provided with a limit chute 3, and the bottom of the limit track 2 is fixed with a fixed track 4. There are two fixed tracks 4, which are respectively located at the bottom of both sides of the limit track 2 in the length direction. The length of the fixed track 4 is less than the limit. The length of the bit track 2, and the center line of the vertical direction of the fixed track 4 and the center line of the vertical direction of the limit track 2 are on the same straight line, and the movable track 5 is installed at both ends of the fixed track 4, and the movable track 5 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com