Both-way iron wire bending device

A bending device and iron wire technology, which is applied in the field of iron wire processing equipment, can solve the problems of large bends, poor control of bend angles at bends, and inability to produce products, achieving rapid production and high bending efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

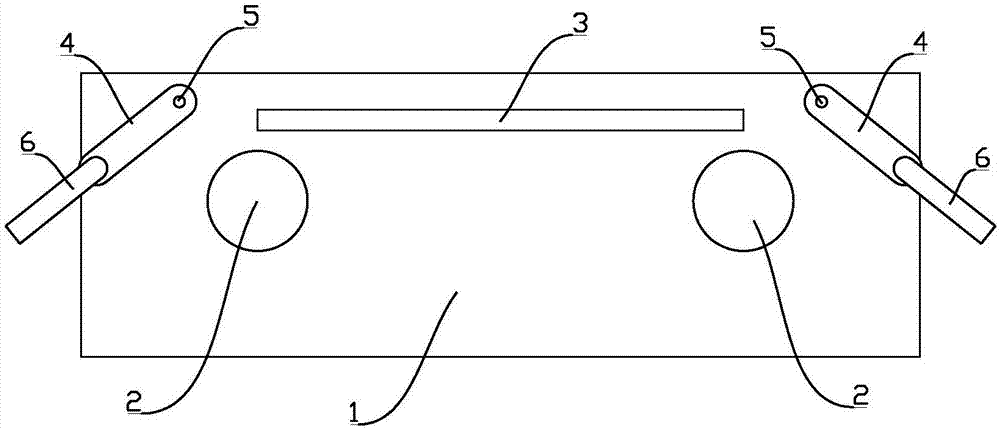

[0012] Such as figure 1 As shown, a two-way bending device for iron wire includes a bottom plate 1, a disc-shaped boss 2 is fixed at both ends of the bottom plate 1, and the bottom plate 1 is above the two disc-shaped bosses 2. A retaining bar 3 is fixed, the distance between the two disc-shaped bosses 2 and the retaining bar 3 is equal, and the base plate 1 is respectively provided with a bending drive rod 4 on the outer side of the disc-shaped boss 2, so that One end of the bending driving rod 4 is rotationally connected with the bottom plate 1 through a rotating shaft 5 , and a handle 6 is fixed at the other end of the bending driving rod 4 .

[0013] The rotating shaft 5 is located above the outer side of the disc-shaped boss 2, and when the bending drive rod 4 is rotated to the vertical position, the distance between the bending drive rod 4 and the disc-shaped boss 2 is equal to the disc shape. The distance between the boss 2 and the bar 3 is equal.

[0014] When the pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com