Prediction method of flexible-packaging lithium-ion battery packaging stress

A technology for encapsulating stress and ion batteries, which is applied in electrical digital data processing, special data processing applications, instruments, etc. It can solve the problems of changing the force mode of soft-pack lithium-ion batteries without considering the increase in encapsulation stress and so on.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] Exemplary embodiments, features, and other aspects of the present invention will be described in detail below with reference to the accompanying drawings. The same reference numbers in the figures indicate functionally identical or similar elements. While various aspects of the embodiments are shown in drawings, the drawings are not necessarily drawn to scale unless specifically indicated.

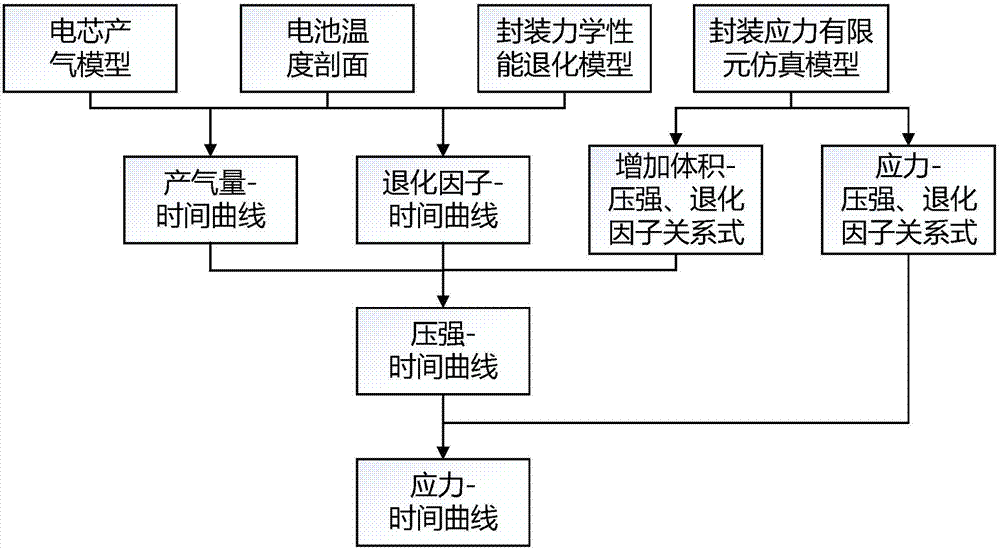

[0047] The present invention is described in further detail in conjunction with a specific soft pack lithium-ion battery for a certain new energy vehicle now, as figure 1 Shown, the specific implementation steps of its invention are as follows:

[0048] Step 1: Determine the battery temperature profile;

[0049] "Battery temperature profile" refers to the daily duration of soft-pack lithium-ion batteries at different temperatures in different states calculated based on historical monitoring data of similar models of soft-pack lithium-ion batteries or based on user usage frequency ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com