Photovoltaic module with novel battery string connection structure

A photovoltaic module and connection structure technology, applied in photovoltaic power generation, circuits, electrical components, etc., can solve the problems of increasing the recovery period, the investment of related cable costs, and affecting the use of cables, so as to reduce the use of wires and improve the safety factor. , the effect of reducing internal resistance consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment example 1

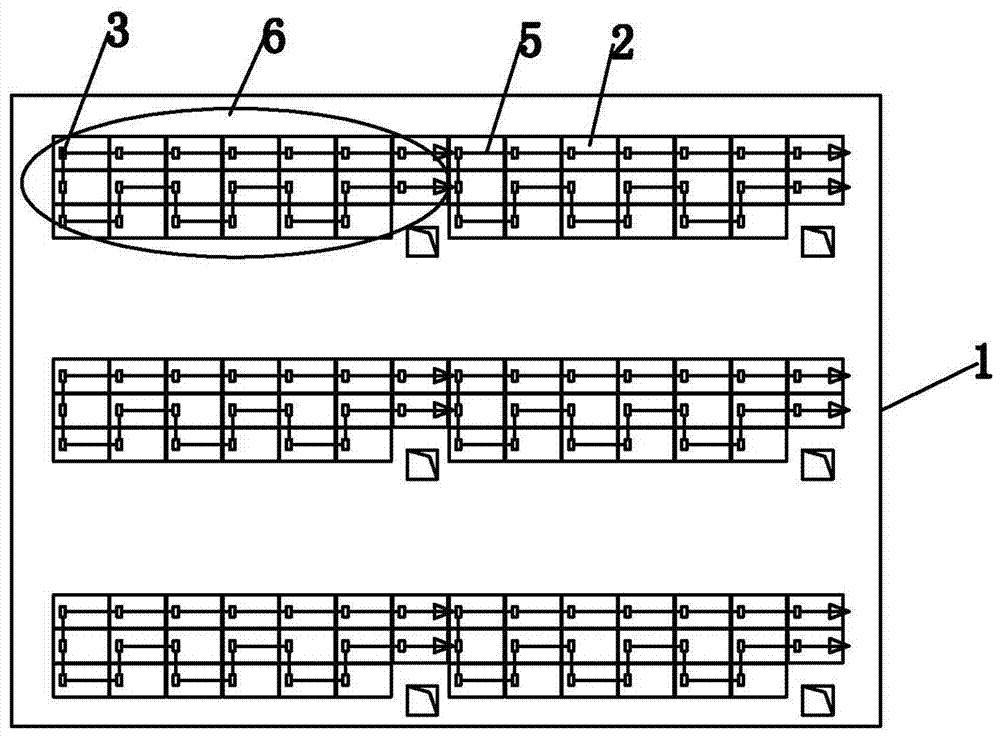

[0026] Depend on figure 1 , figure 2 It can be seen that each photovoltaic module 1 is composed of M (M=120) cells 2, and the M cells 2 are divided into P (P=3) groups, and each group of cells 2 is divided into left and right groups. , the right two parts,

[0027] The battery slices 2 of the battery string I6 in the first group are distributed in the column I (I is within the integer range of 1-7) and the row J (J=1, 2, 3), and the battery slices 2 of the battery string II7 are distributed in the I ( I is in the range of 8-14 integers) column, J (J=1, 2, 3) row;

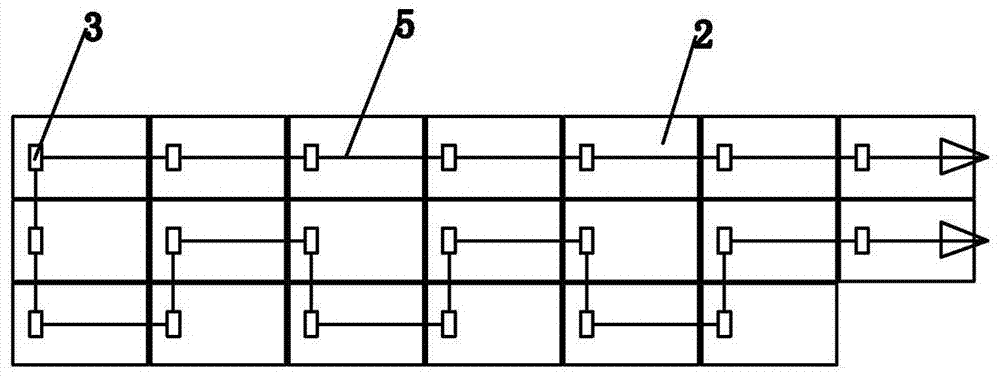

[0028] Taking the battery string I6 as an example, the figure 2 It can be seen that one end of the wire 5 is fixed on the battery sheet 2 with J=1 and I=7, and the other end of the wire 5 crosses the first row, and then connects with the battery sheet with J=2, I=1, J=3, I=7 in sequence. =1 cell, J=3, I=2 cell, J=2, I=2 cell, J=2, I=3 cell, J=3, I=3 cell, J=3, I =4 cells, J=2, I=4 cells, J=2, I=5 cells, J=3,...

Embodiment example 2

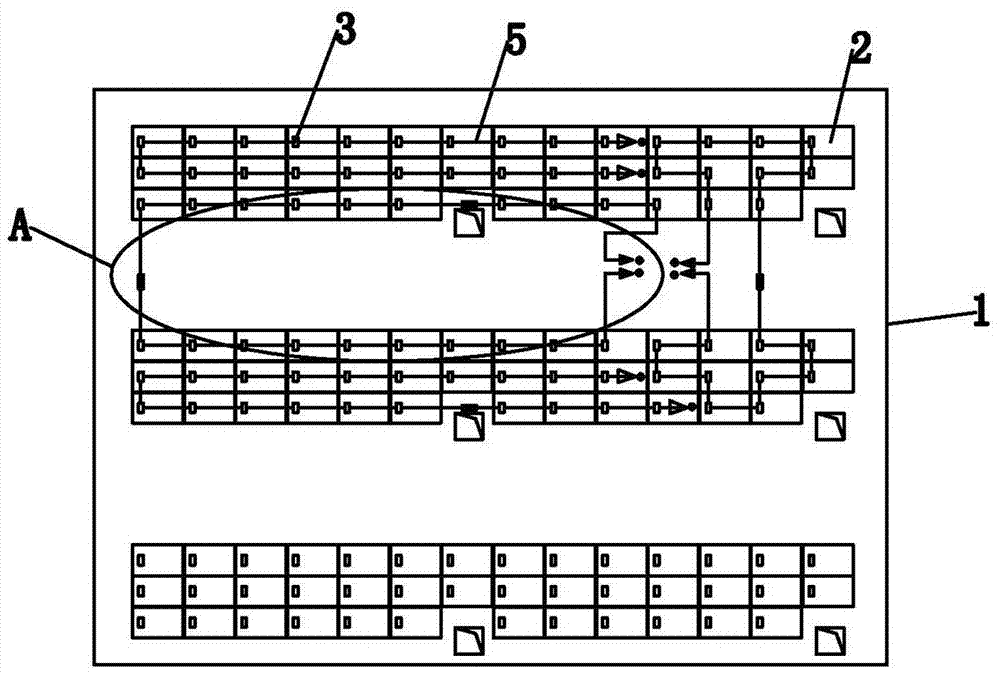

[0033] Depend on Figure 5 , Figure 6 It can be seen that each photovoltaic module 1 is composed of M (M=132) cells 2, and the M cells 2 are divided into P (P=3) groups, and each group of cells 2 is divided into left and right groups. , the right two parts,

[0034] The battery slices 2 of the battery string I6 in the first group are distributed in column I (I is within the integer range of 1-6) and row J (J=1, 2, 3, 4), and the battery slices 2 of battery string II7 are distributed in I (I is within the integer range of 7-12) column, J (J=1, 2, 3, 4) row;

[0035] Taking the battery string II7 as an example, the figure 2 It can be seen that one end of the wire 5 is fixed on the battery sheet 2 with J=1 and I=12, and the other end of the wire 5 crosses the first row, and then connects with the battery sheet with J=2, I=7, J=2, I=7 in sequence. =8 cells, J=3, I=8 cells, J=3, I=7 cells, J=4, I=7 cells, J=4, I=8 cells, J=4, I =9 cells, J=3, I=9 cells, J=2, I=9 cells, J=2, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com