Threading device

A threader and threading technology, which is applied in the field of threaders, can solve the problems of low threading efficiency, lower threading work efficiency, and slow traction speed, etc., and achieve the effects of speeding up threading efficiency, speeding up movement, and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

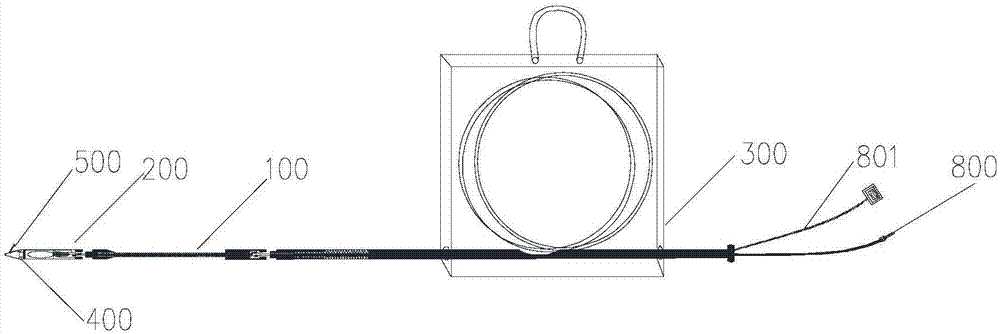

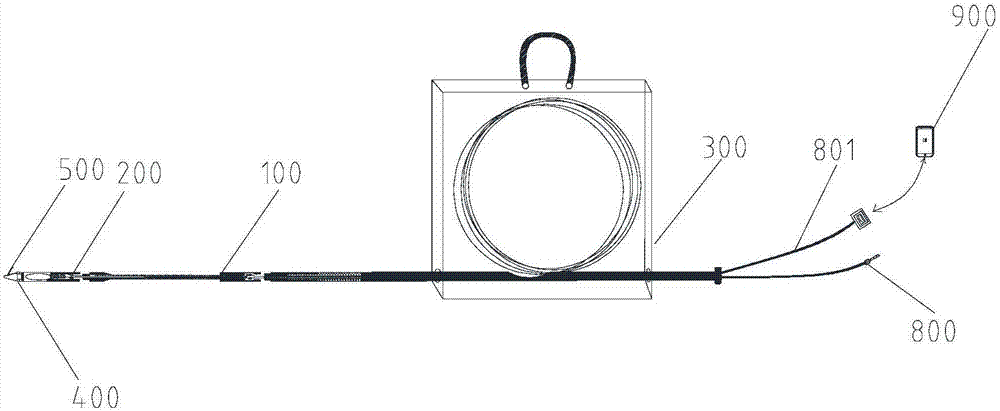

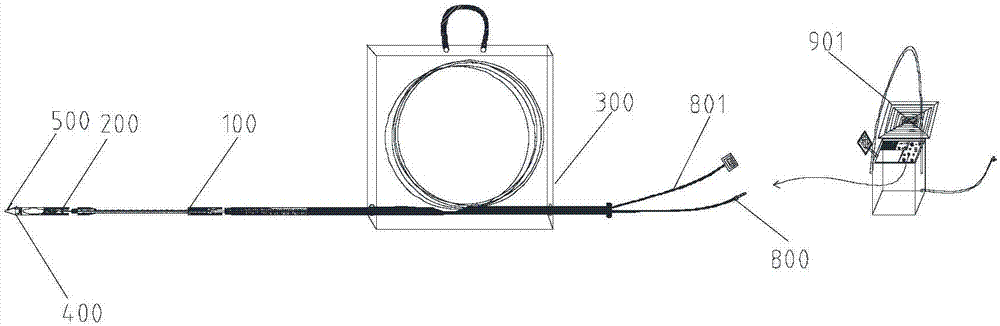

[0049] According to one aspect of the present invention, as figure 1 As shown, a threader is provided, including a threader main body 100, a threading probe 200, a hanging wire assembly 300, and a plurality of rolling assemblies 400 rollingly connected with the pipeline;

[0050] The threading probe 200 is arranged at one end of the threader main body 100, and the thread hanging assembly 300 is arranged at the other end of the threader main body 100;

[0051] Each rolling assembly 400 is installed on the threading probe 200 so that the threading probe 200 is in rolling connection with the pipeline.

[0052] According to the threader of the present invention, during the threading process of the threader in the pipeline, since the rolling assembly 400 on the threading probe 200 is rollingly connected with the pipeline, the rolling assembly 400 can roll in the pipeline, and the rolling assembly 400 The rolling of the threading probe 200 can speed up the movement of the threading...

Embodiment approach

[0063] According to an embodiment of the threader of the present invention, the cleaning component 500 is a scraper 501 and a hook 502; the tip 201 is provided with an opening 503 compatible with the scraper 501 and a depression 504 compatible with the hook 502;

[0064] One end of the scraper 501 is equipped with a hook 502;

[0065] The other end of the scraper 501 is rotatably connected to the tip 201 so that the scraper 501 and the hook 502 have a first station and a second station relative to the tip 201;

[0066] When the scraper 501 and the hook 502 are in the first position relative to the tip 201, the scraper 501 covers the opening 503, and the hook 502 is hooked at the recess 504; when the scraper 501 and the hook 502 are relative to the tip When 201 is in the second position, the scraper 501 and the hook 502 form an angle with respect to the tip 201 .

[0067] According to the threader of the present invention, the main function of the cleaning assembly 500 is to d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com