Linear up-down vibration motor comprising shell formed by magnetic field closed circuit

A technology of closed circuit and vibrating motor, which is applied in the direction of electric components, electrical components, electromechanical devices, etc., can solve the problems of high vibration difficulty and unguaranteed life, and achieve the effect of reducing the combination failure rate, improving vibration force and reducing tremor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

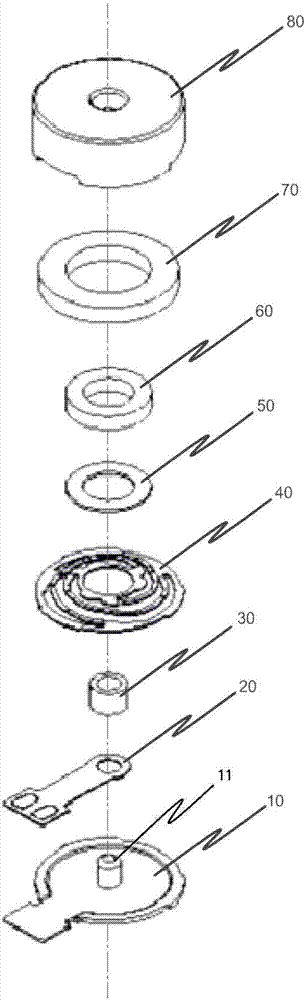

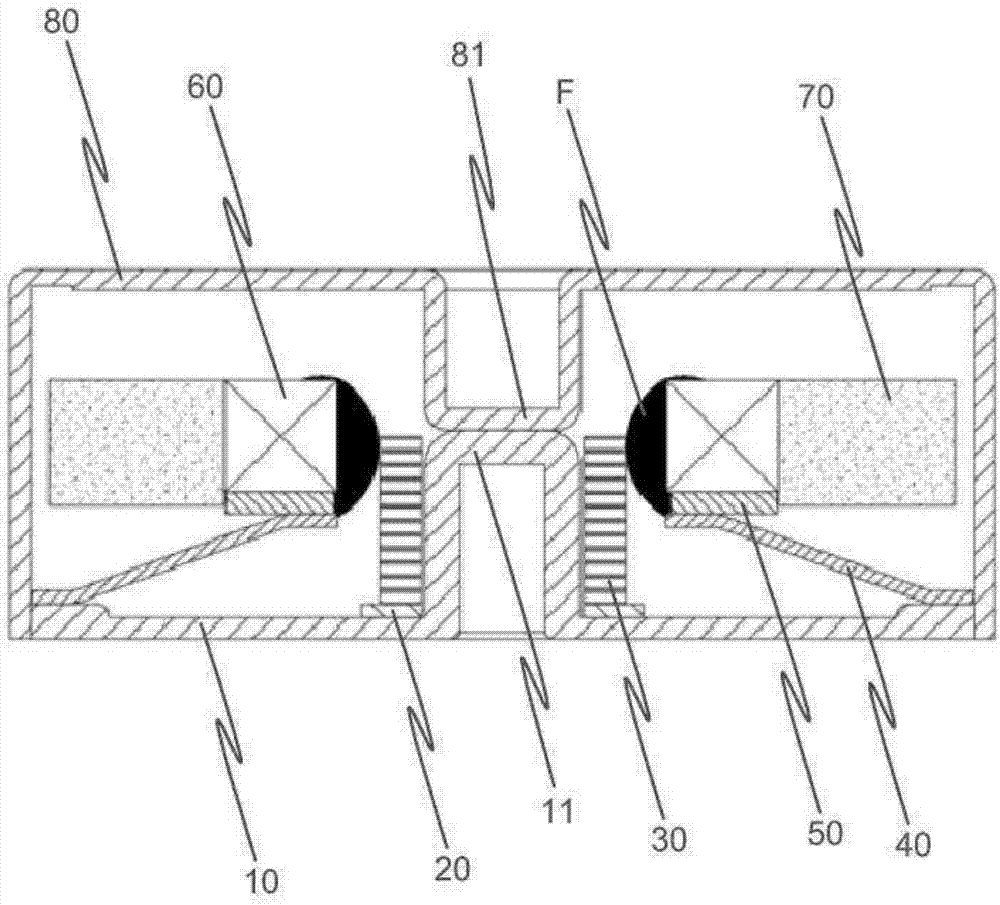

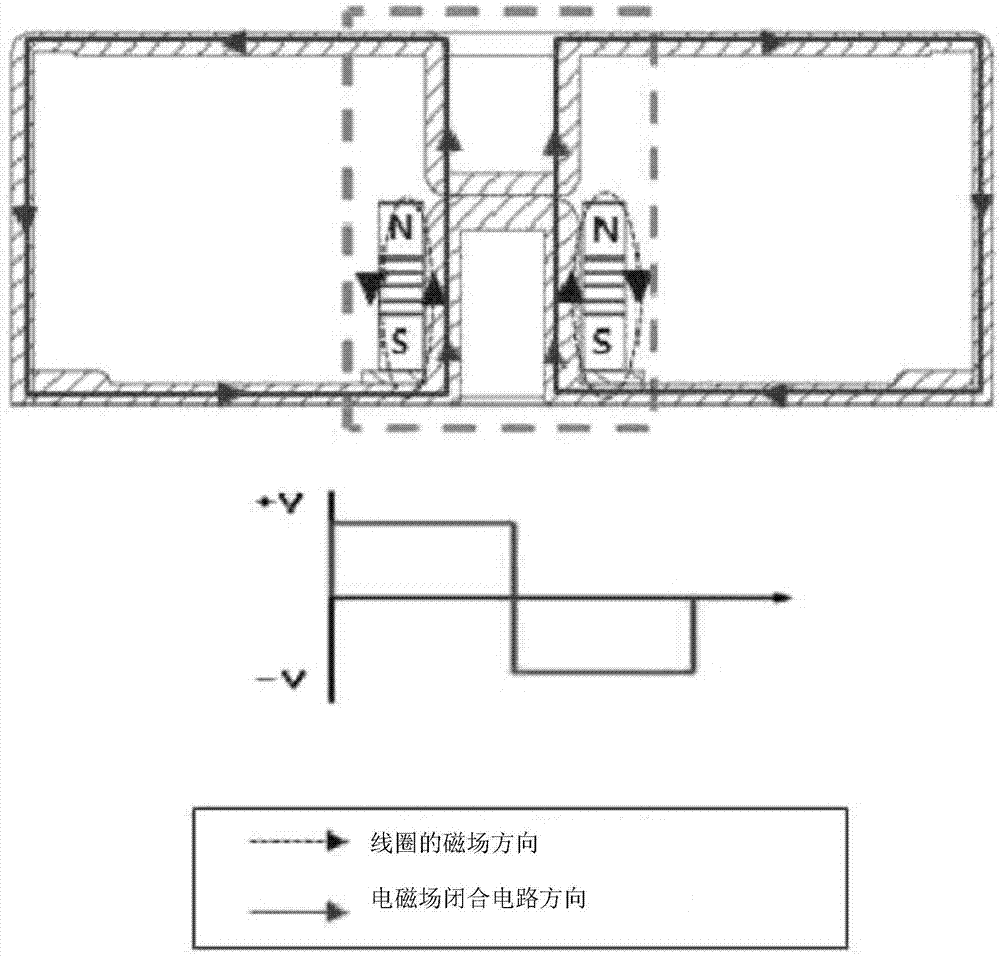

[0049] Hereinafter, various modifications and various embodiments of the present invention are possible, and specific embodiments are illustrated in the drawings and described in detail. However, the present invention is not limited to a specific embodiment, and all modifications, equivalents, and substitutions belonging to the spirit and technical scope of the present invention are included. The purpose of this embodiment is to help those skilled in the art better understand the present invention. Therefore, in order to better explain the shape of each element shown in the drawings, the shape may be exaggerated. In the process of describing the present invention, if it is considered that the specific description of the related disclosed technology hinders the understanding of the present invention understanding, its detailed description will be omitted.

[0050] Hereinafter, preferred embodiments of the present invention will be described in detail with reference to the acco...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com