Gas, solid and liquid reaction device

A technology of reaction device and reaction tank, which is applied in feeding device, chemical/physical/physical-chemical stationary reactor, mixer with rotary stirring device, etc. Problems such as detachment damage, air intake pipe fixing and blockage are difficult to solve, so as to prevent easy blockage and prevent loose damage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention can be better described below in conjunction with the accompanying drawings and specific embodiments.

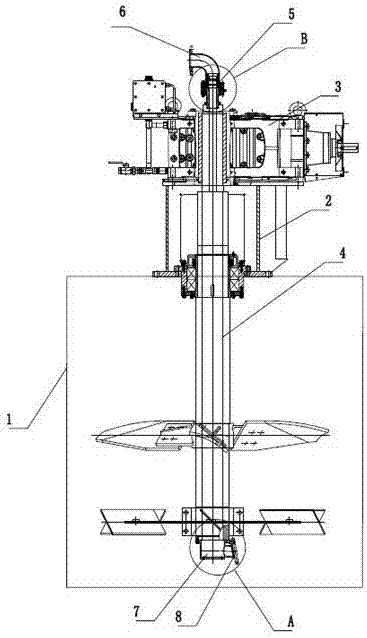

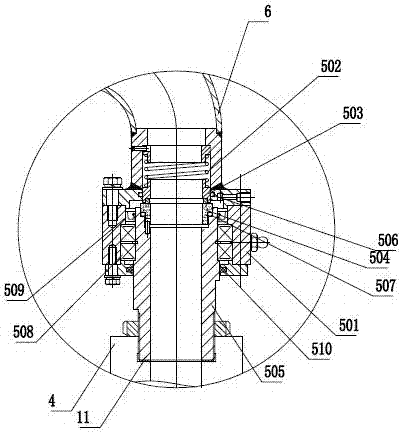

[0017] A gas, solid and liquid reaction device, comprising a reaction tank 1, a frame 2, a driving device 3 and a stirring shaft 4, the frame 2 is installed on the reaction tank 1, and the driving device 3 is installed on the frame 2, the driving device 3 drives the stirring shaft 4 to rotate, the stirring shaft 4 extends into the inner cavity of the reaction tank 1, the stirring shaft 4 is a hollow structure, and the upper end of the stirring shaft 4 passes through the rotary joint 5 It is connected with an air intake pipe 6 . The air is directly fed through the hollow stirring shaft, and there is no additional vent pipe inserted into the reaction tank, which eliminates the loosening, damage and easy blockage of the vent pipe that often occurs during the stirring operation of the reaction tank.

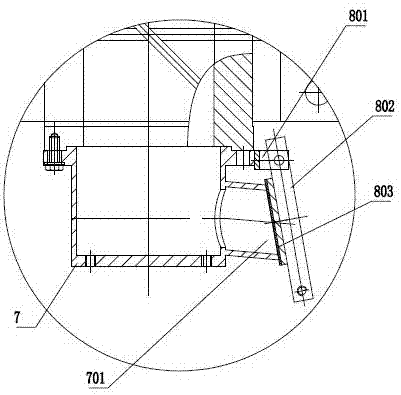

[0018] The lower end of the stirring shaft 4 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com