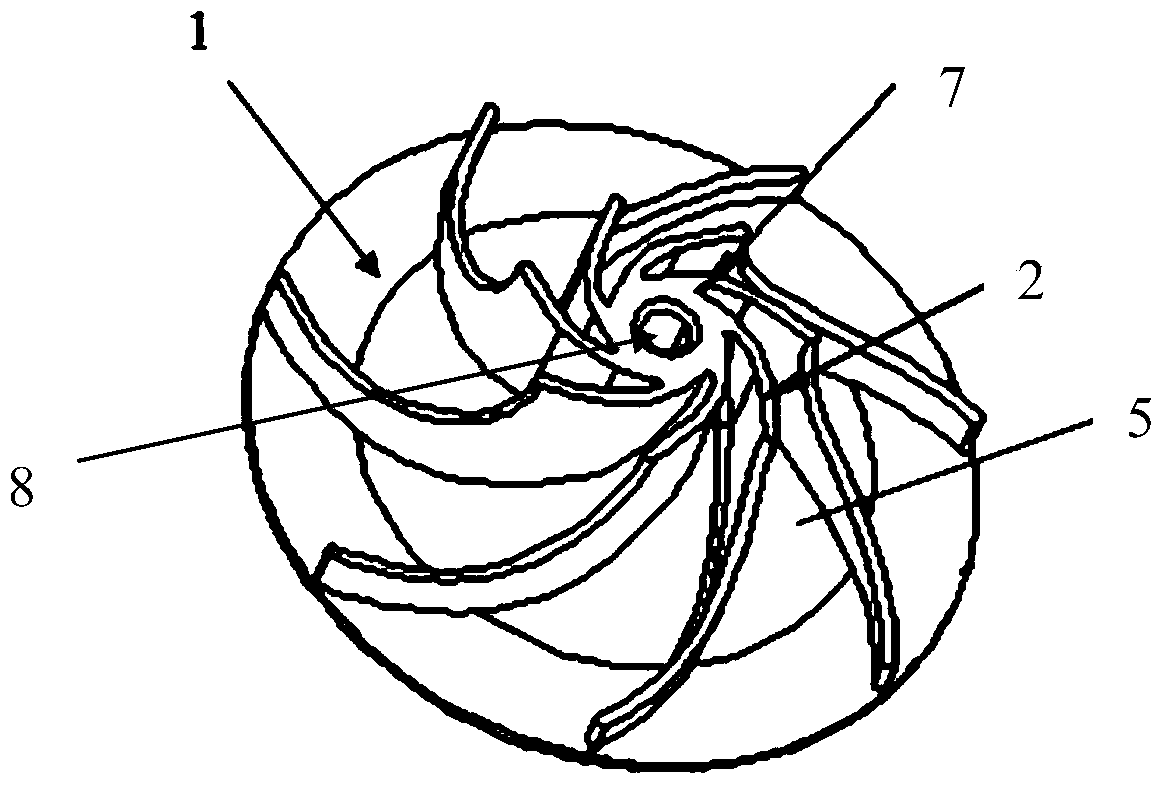

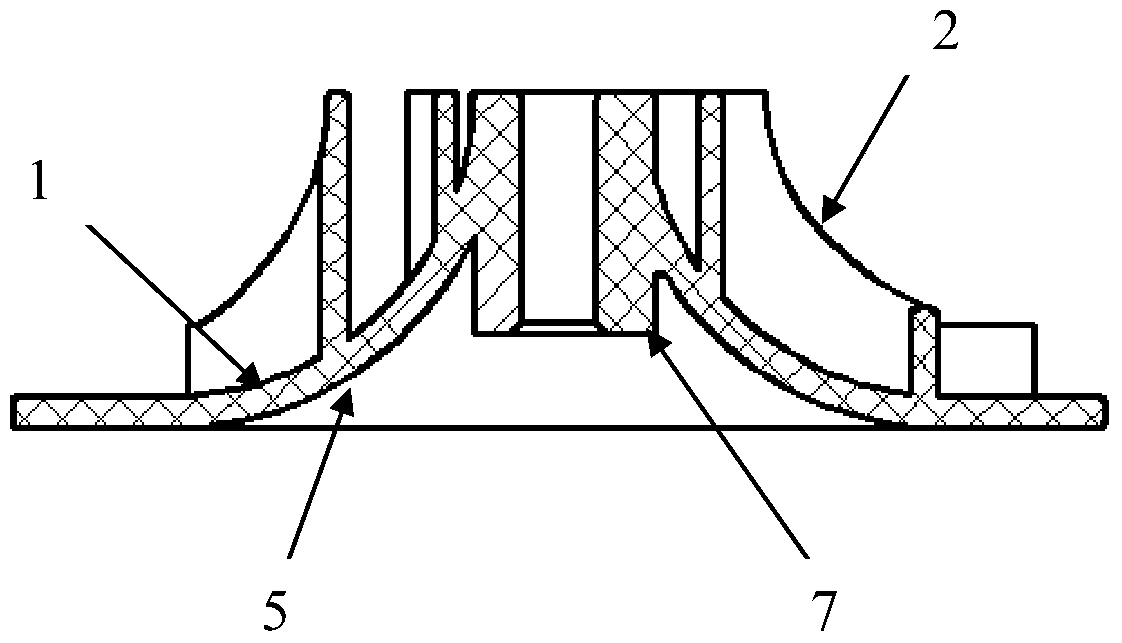

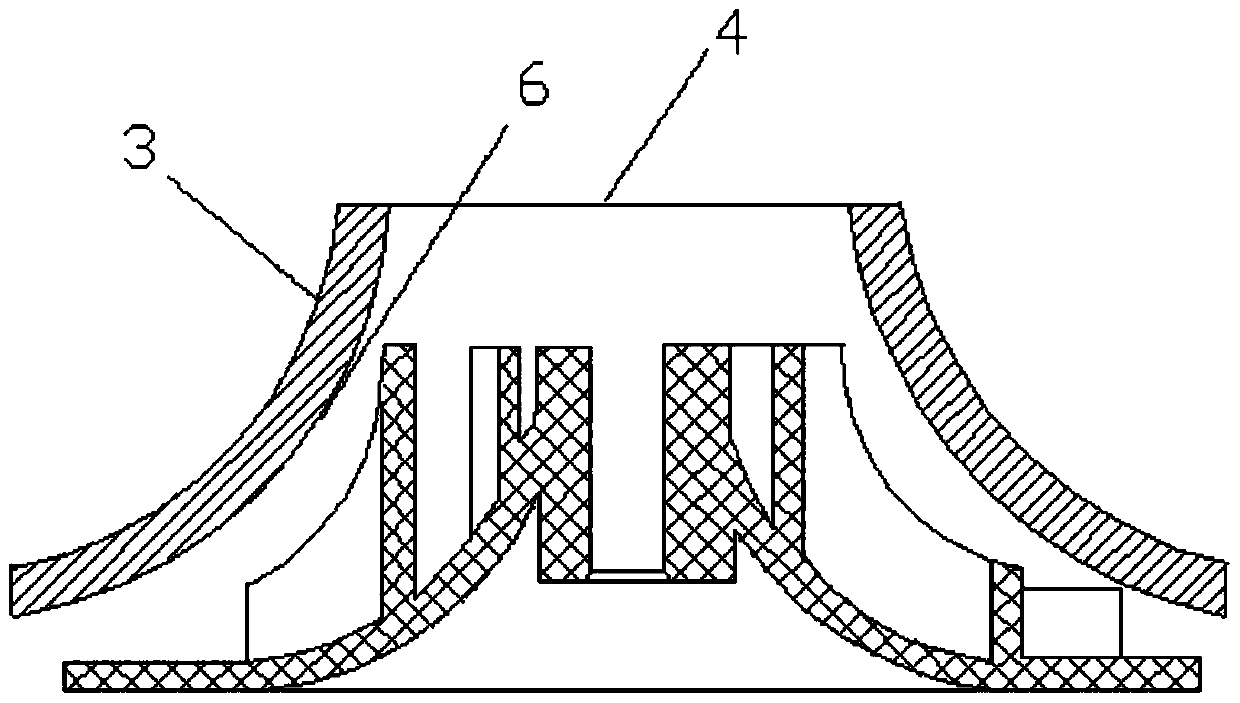

an impeller

An impeller and impeller cover technology, which is applied to the components of the pumping device for elastic fluids, non-variable displacement pumps, machines/engines, etc., can solve the problems of low impeller structure performance, high use cost, high energy consumption, etc. , to achieve the effect of compact structure, less material usage and high structural strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The impeller of the traditional vacuum cleaner motor is made of aluminum, which is a closed impeller structure, usually including an upper cover, a lower cover, and blades arranged between the upper and lower covers. The closed impeller has a higher working efficiency, but It is difficult to manufacture, and the upper and lower cover plates and blades of the aluminum impeller are assembled, the structure is complex, the upper and lower cover plates are easy to loosen and damage, and generally the volume is large, the quality is heavy, the production cost is high, and the noise during operation larger. Moreover, generally the upper and lower cover plates are of flat plate structure, and the blades are evenly distributed between the upper and lower cover plates. In order to increase the working efficiency of the impeller, the length of the blades must be increased, so that the area of the upper and lower cover plates needs to be enlarged, resulting in the Overall volume...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com